At CES 2020 (the major consumer electronics trade show in Las Vegas), the Sony Group announced that it would be venturing further into the mobility business, with a sleek prototype car called the VISION-S. At that time, though, what it displayed seemed to be a concept car to show off various technologies, which is also done by other electronics companies

However, the company was actually going further with the concept car and began quietly developing it into a running prototype. By CES 2021, it revealed that there was a running prototype and it was being tested on public roads and on a test track in Austria. Engineers also started verification tests of the safety and user experience of the imaging and sensing technology installed inside and outside the vehicle, along with the human-machine interface (HMI) system.

Second prototype displayed

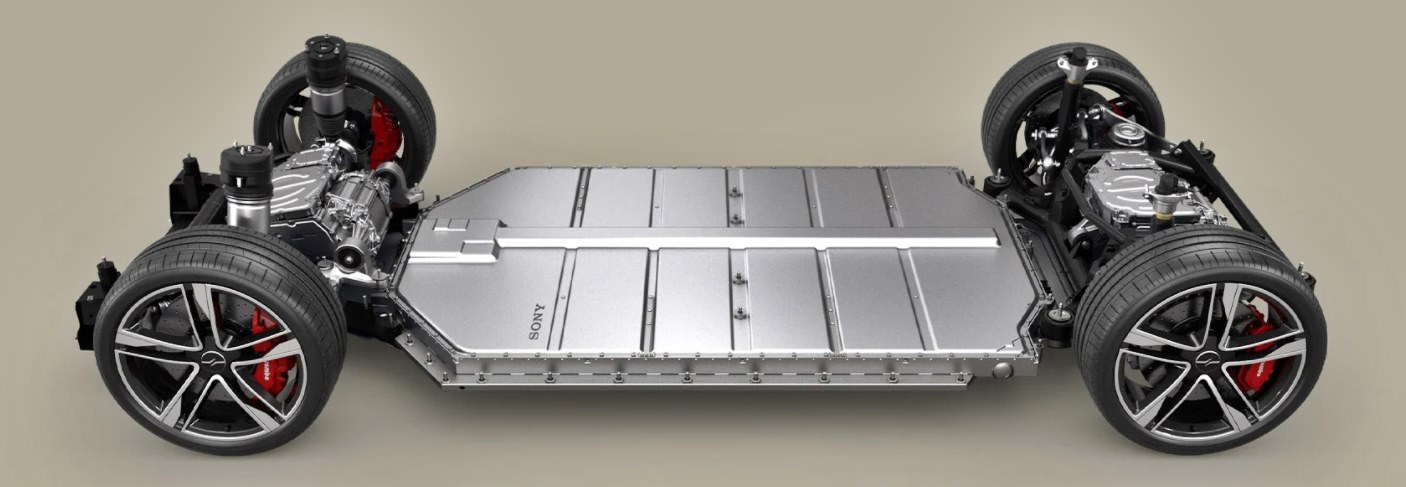

At CES 2022 this week, Sony has not only provided an update on the progress of the project but is also displaying a second prototype, the VISION-S 02. This has a SUV design as a new form factor and rides on the same EV/cloud platform as the original VISION-S 01 prototype. By offering entertainment experiences utilizing the large interior space and variations of a 7-seater, this new prototype will promote the accommodation of a large variety of lifestyles within a society where values are becoming increasingly diversified.

The VISION-S 02 measures almost 4900 mm long and 1930 mm wide, which is about the size of a Lexus RX300. It has 200 kW electric motors powering the front and rear wheels so there’s all-wheel drive and the claimed top speed is expected to be over 180 km/h.

Advanced sensor system

Electronics are obviously one of Sony’s strengths and it has been developing a sensors system to support the driver. The system recognizes and analyzes the surrounding environment in real-time, using sensors installed to cover all around the vehicle. These sensors include high-sensitivity, high-resolution, wide dynamic range CMOS image sensors and LiDAR sensors that accurately sense 3-dimensional space.

In addition, the system provides intuitive driver interaction in conjunction with the vehicle’s sound system and HMI system, so that the driver can accurately judge the status of the surrounding environment, such as the presence of emergency vehicles, even from inside the vehicle.

Time-of-Flight (ToF) sensors are used to provide monitoring functions for driver authentication and to watch over passengers. They also support intuitive gesture and voice commands that are intended to enhance usability of the car interface. Additionally, in order to deliver an environment that suits each user’s preferences, the vehicle will include a new function that allows users to customize the display theme and the acceleration and deceleration sounds of the vehicle.

Vehicle settings, key locks, and user settings can be synchronized by linking the vehicle to the cloud using mobile communication, including 5G communication, which features low-latency, high-capacity, and high-speed capabilities. In addition, since updates are reflected in the vehicle via over the air (OTA), it is possible to provide security and evolve service functions and value-added offerings continuously.

5G connectivity

5G driving tests were also conducted from April 2021, the next-generation network connectivity enabling a continuous connection between the in-vehicle systems and the cloud, in order to synchronize data and control signals, and update the systems OTA (Over The Air).

“Real time mobile communication turns cars into databases on wheels. In our 5G Mobility Lab, the VISION-S Prototype learns to communicate in real time. Together with Sony, we are preparing the first prototype for 5G so that in the future new features can be imported into the car over the air and with a simple software update,” said Hannes Ametsreiter, CEO of Vodafone Germany, which is collaborating with the Japanese company.

Utilizing Sony’s in-house technologies and knowledge of communication technology and security cultivated through the development of smartphones, it has positioned remote operation as an important technology in anticipation of the arrival of the autonomous driving era.

Enriching the mobility entertainment space

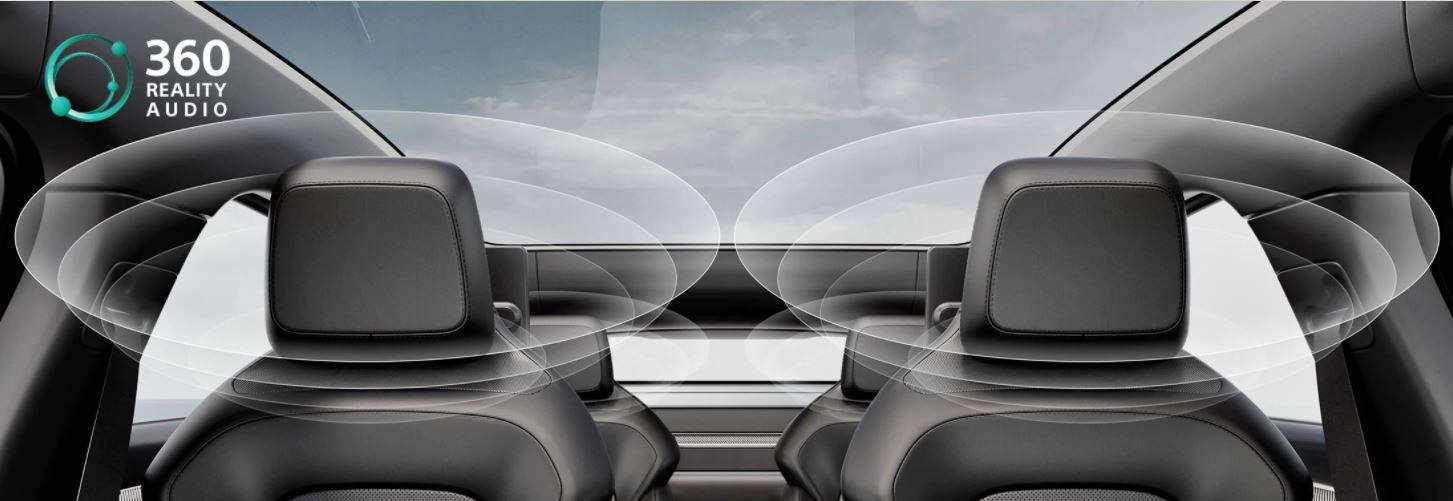

The seat speakers, which create a three-dimensional sound field, and the streaming service compatible with ‘360 Reality Audio’ provide an immersive music experience. The high quality would only be expected from Sony, which has a strong reputation in this field.

In addition, to provide a high-quality movie experience, the VISION-S models include the fully integrated digital video service ‘BRAVIA CORE for VISION-S’. The service enables shared or individual video playback on the front panoramic screen and individual rear-seat displays. Further extending the possibilities of in-vehicle entertainment, gaming capabilities have expanded to being able to play PlayStation games through a remote connection to a console at home, in addition to the ability to play streaming games through the cloud.

To make the best use of AI and robotics technologies, Sony will soon establish an operating company called Sony Mobility Inc., through which the company intends to explore entry into the EV market.