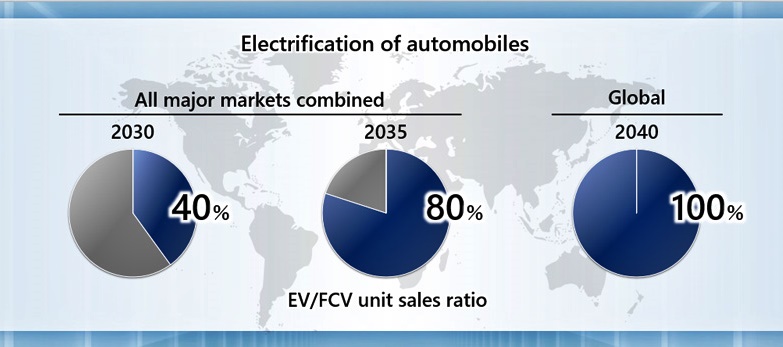

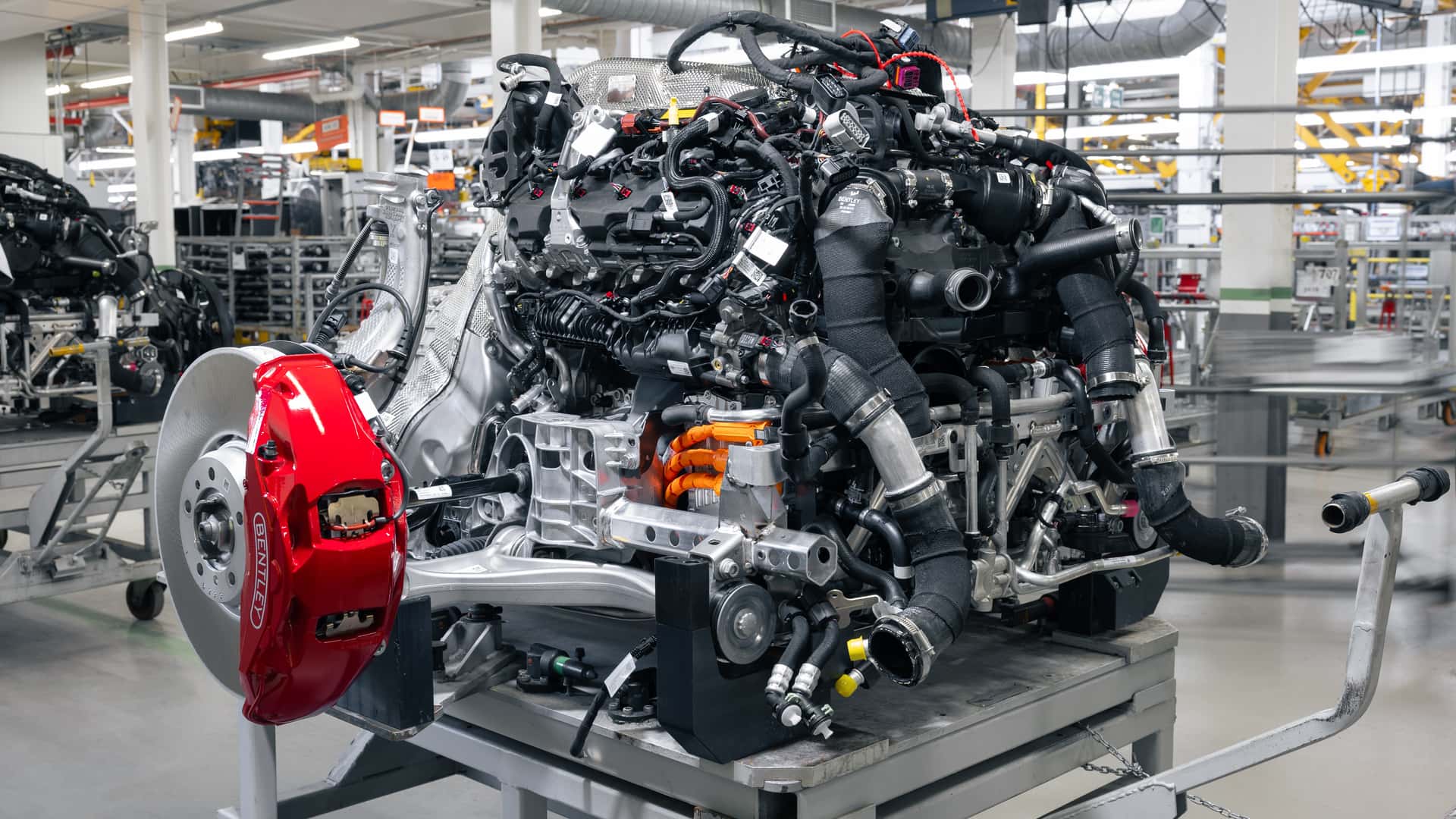

The auto industry is accelerating towards electrification of products, ultimately leaving behind the combustion engine that has been blamed for causing pollution of the environment and bringing on climate change. However, unlike previous transitions, this one is a radical one that calls for a change in the ecosystem of the industry. The existing ecosystem has evolved over 100 years around the combustion engine and now, with electrification, manufacturing processes and supply chains need to be changed.

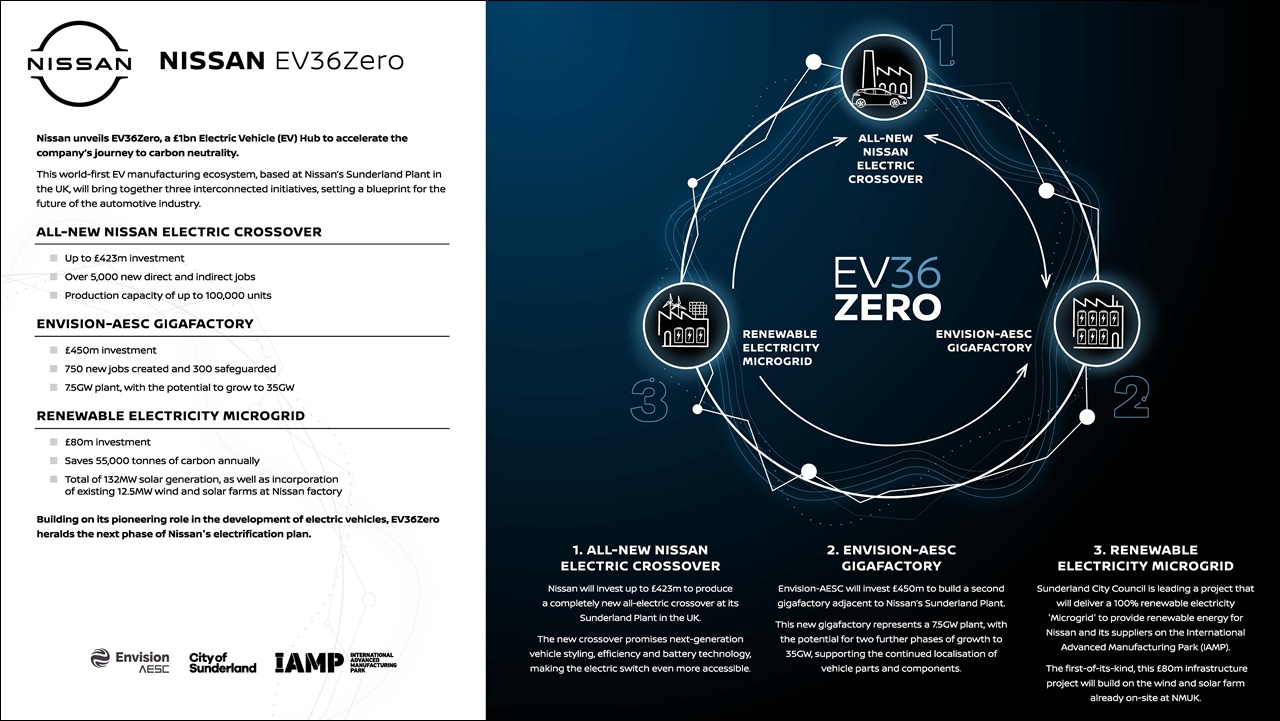

Different carmakers are taking different approaches and Nissan will make a total investment of £1 billion (about RM5.82 billion) in establishing a flagship Electric Vehicle (EV) Hub as a world-first EV manufacturing ecosystem. To be known as Nissan EV36Zero, the core of this hub will be at its 35-year old manufacturing complex at Sunderland in the United Kingdom.

The transformational project has Envision AESC, a global player in world-leading battery technology, and the Sunderland City Council as partners. Made up of three interconnected initiatives, Nissan EV36Zero brings together electric vehicles, renewable energy and battery production, setting a blueprint for the future of the automotive industry.

“This project comes as part of Nissan’s pioneering efforts to achieve carbon neutrality throughout the entire lifecycle of our products. Our comprehensive approach includes not only the development and production of EVs, but also the use of on-board batteries as energy storage and their reuse for secondary purposes,” said Nissan President & CEO, Makoto Uchida. “The experience and know-how gained through the project will be shared globally, enhancing Nissan’s global competitiveness.”

Building on Nissan’s historic presence in Sunderland, the projects represent 6,200 jobs at Nissan and its UK suppliers, including more than 900 new Nissan jobs and 750 new Envision AESC jobs at its new smart, low-carbon battery plant. Longer-term, the transformational project modernises and expands Nissan’s EV production capability in the UK.

Envision AESC will deploy integrated AIoT smart technology to monitor and optimize energy consumption, manufacturing and maintenance at its new gigafactory, enabling it to rapidly increase production and provide batteries to power up to 100,000 Nissan electric vehicles a year.

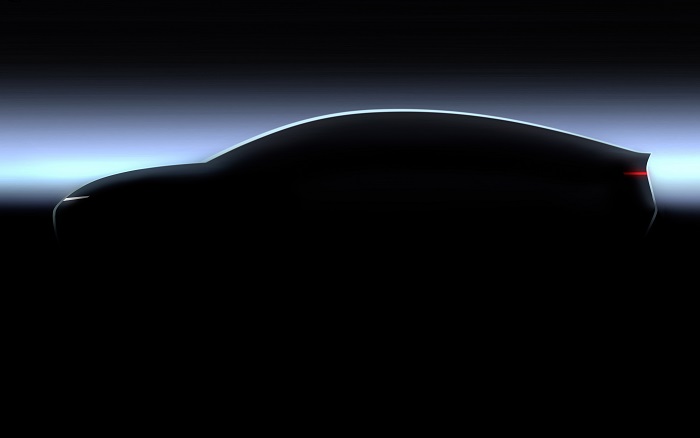

New-generation electric crossover

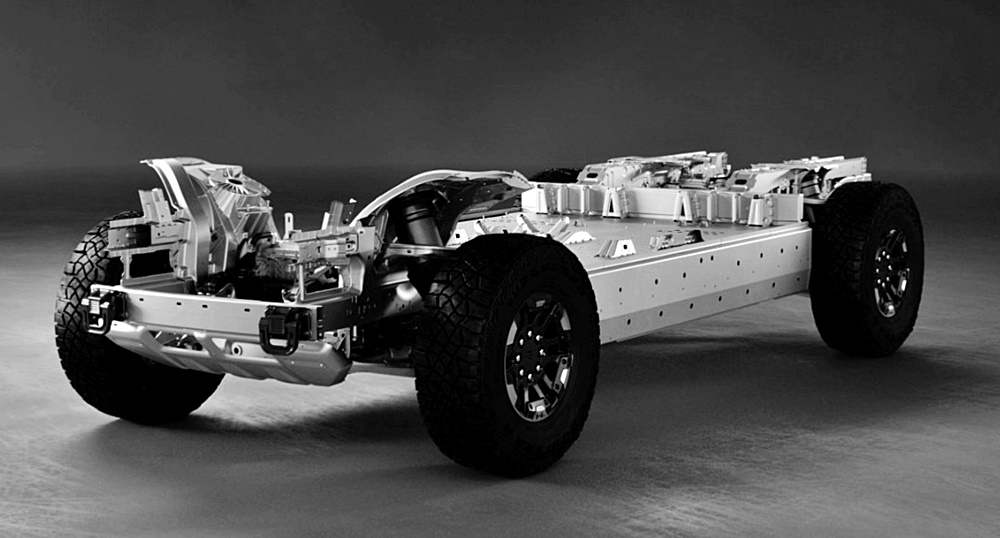

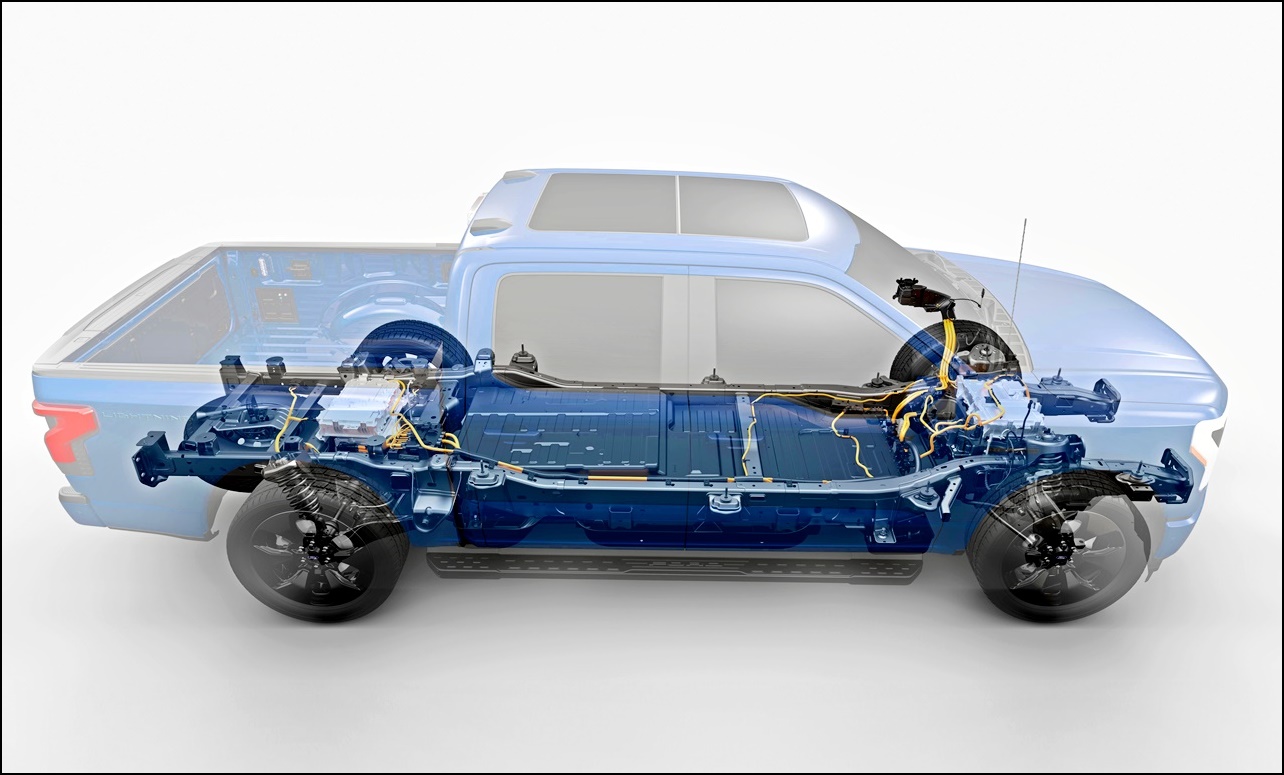

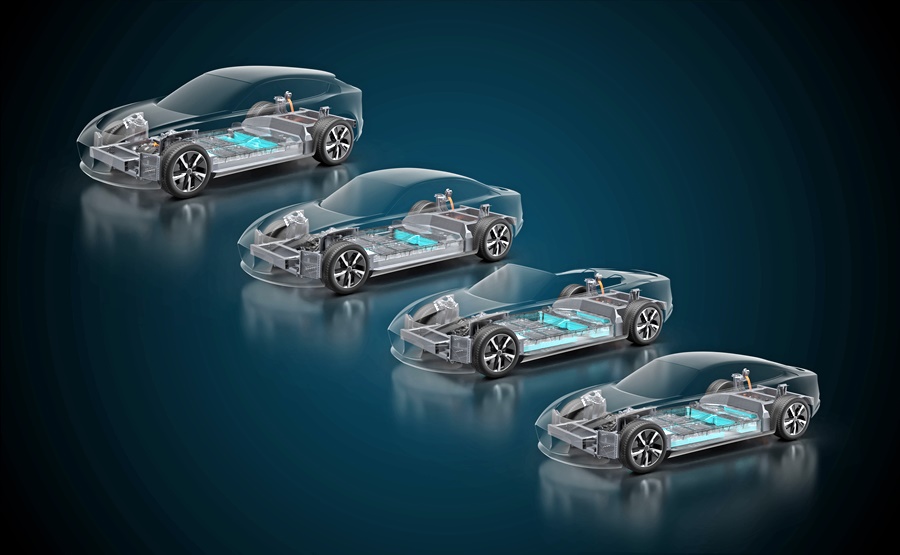

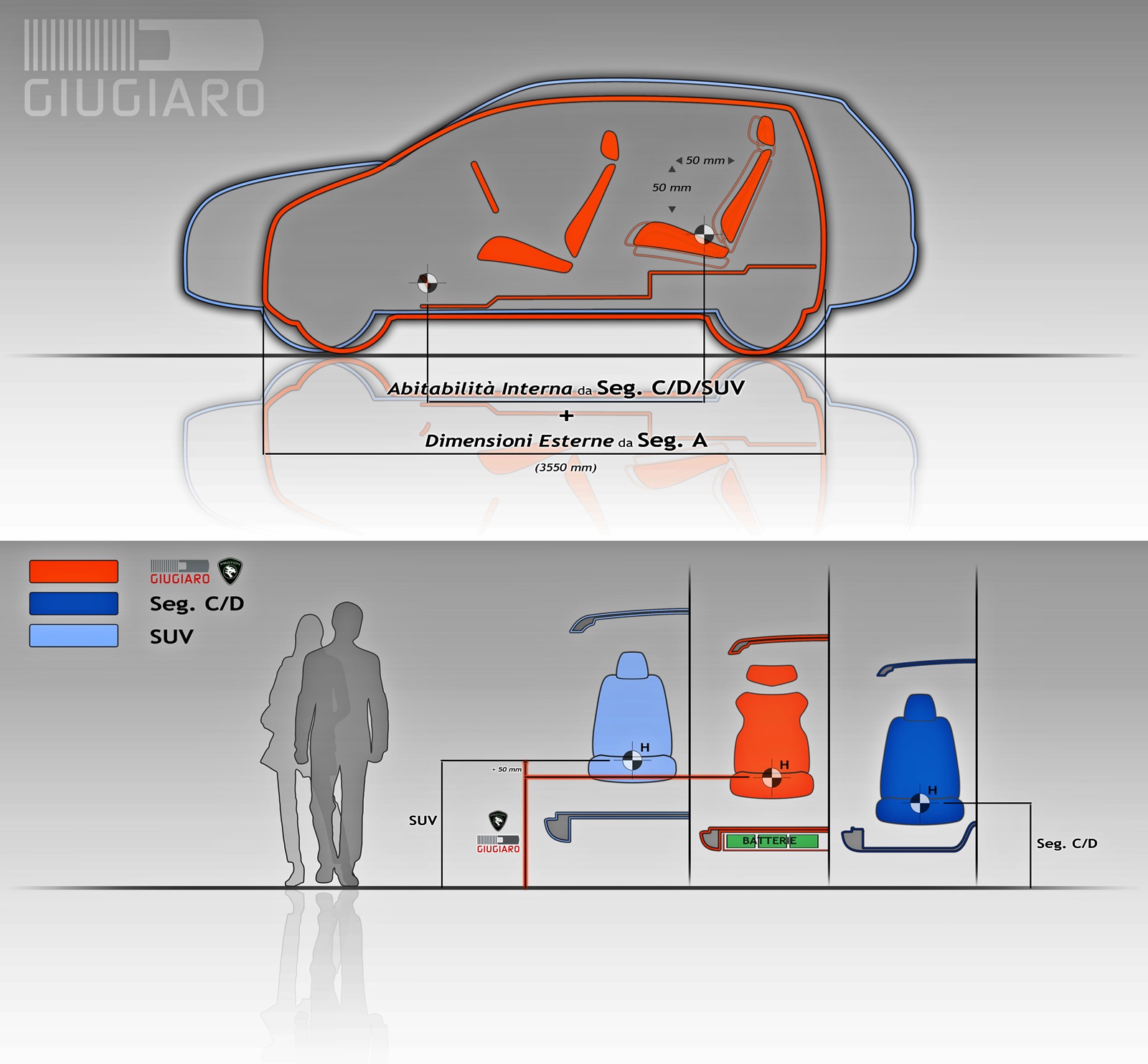

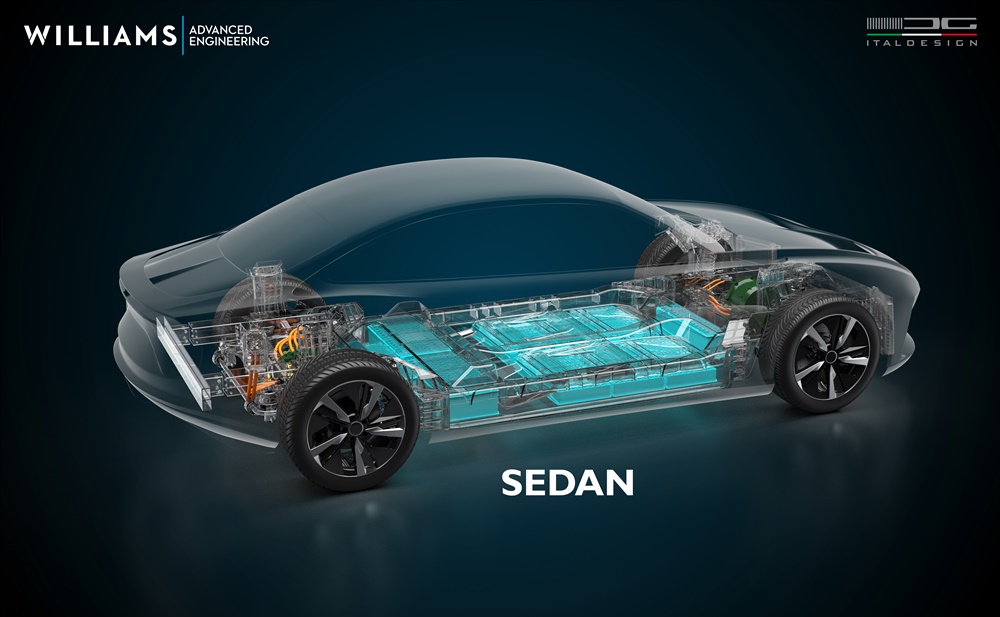

As part of the investment, Nissan will invest up to £423 million to produce a new-generation EV in the UK. Utilising the Alliance CMF-EV platform, it will be designed for global markets with forecasted production capacity of up to 100,000 units to be installed.

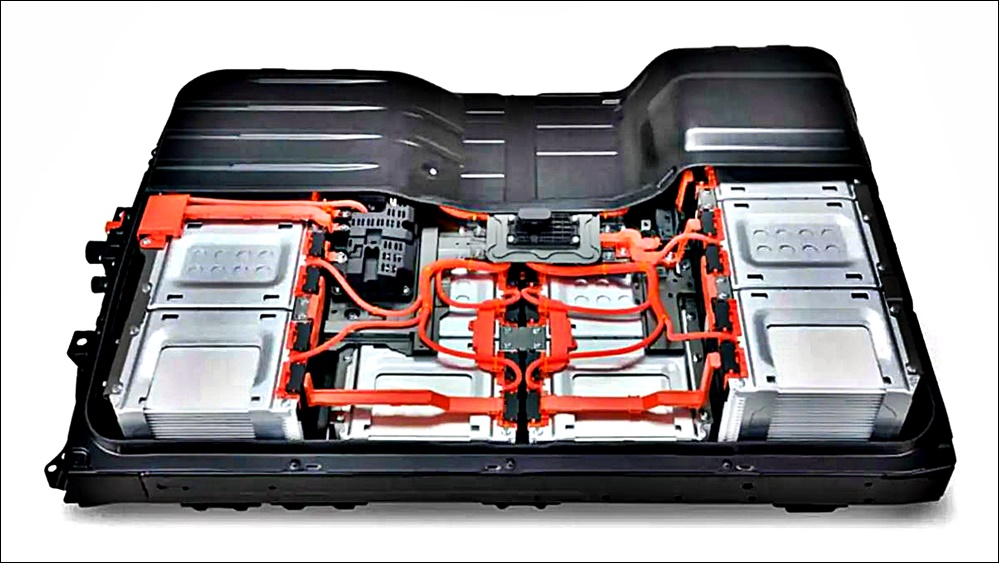

Next-generation EV batteries

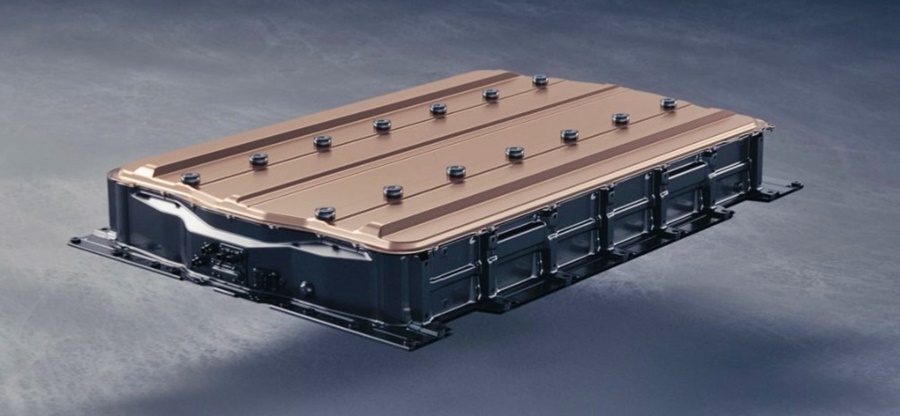

Envision AESC already owns and operates Europe’s first battery plant in Sunderland, established in 2012 for the localisation of Nissan LEAF battery production. The factory’s UK team therefore has 9 years’ expertise of supplying batteries to the Nissan LEAF and eNV200, having produced enough cells, modules and packs to power over 180,000 electric vehicles in 44 countries, meeting global benchmark levels of quality, performance, safety, reliability and cost.

Supporting this new model allocation, Envision AESC will invest £450 million (about RM2.62 billion) to build the UK’s first gigafactory on the International Advanced Manufacturing Park, adjacent to the Nissan plant, powered by renewable energy and pioneering next-generation battery technology. This new plant will increase the cost-competitiveness of EV batteries produced in the UK, including through a new Gen5 battery cell with 30% more energy density which improves range and efficiency. It will also make batteries cheaper and EVs more accessible to a growing number of customers in the future.

Used battery packs have second life

There are also plans for a 1MW battery storage system using second-life Nissan EV/Envision AESC batteries, which will also allow for excess energy generated during daylight hours to be captured and used at another time, helping to balance demand on the grid.

Nissan EVs as mobile power supply units in disaster areas (w/VIDEO)

Nissan EVs as mobile power supply units in disaster areas (w/VIDEO)