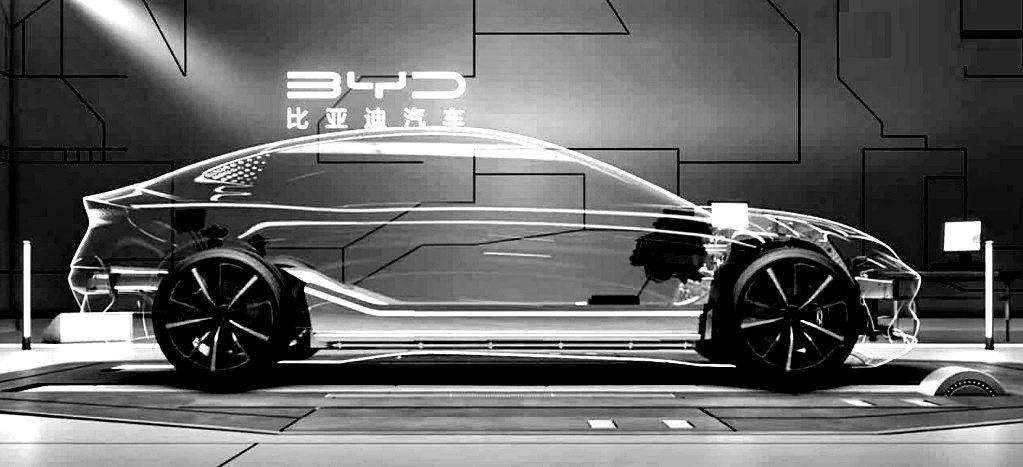

Since being established 73 years ago, Honda Motor has been able to remain independent instead of becoming part of a bigger group. On its own, it has been able to successfully manage its business and endure even the most challenging periods without having to surrender its independence. However, the 21st century sees the auto industry changing and with the move towards electric vehicles (EVs), the cost of developing entirely new technologies is very high. In April, Honda became the first Japanese automaker to declare its intention will stop selling combustion-engines vehicles by 2040.

So even though Honda has preferred to be a ‘lone ranger’, it has been forming strategic alliances with some companies in the area of EVs because it is crucial to remain competitive in the new field, and sharing resources is more realistic. Honda has already agreed with General Motors to jointly develop two all-new EVs for Honda’s range, based on GM’s global EV platform. The EVs will be manufactured at GM plants in North America with sales expected to begin in 2024 for that market.

New joint-venture company

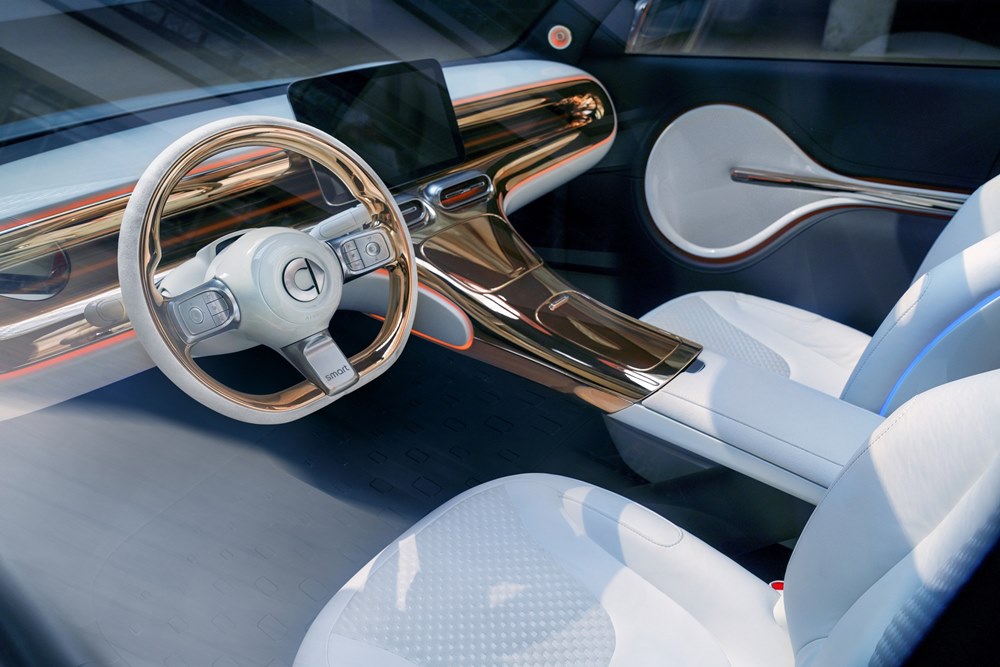

On another front, Honda will be working with Sony Group Corporation to develop EVs as well. The two companies have signed a Memorandum of Understanding (MoU) that outlines their intent to form a joint venture company through which they plan to engage in the joint development and sales of high value-added battery electric vehicles (BEVs) and commercialize them in conjunction with providing mobility services. The new company is expected to be established before the end of this year.

This alliance aims to bring together Honda’s mobility development capabilities, vehicle body manufacturing technology and aftersales service management experience, while Sony has expertise in the development and application of imaging, sensing, telecommunication, network, and entertainment technologies.

Sony has already developed EVs

Honda has already developed a few EV models for sale, with the Honda e having received a good response in Europe. Sony has also been developing its own EVs, with two prototypes displayed earlier this year at CES 2022 in Las Vegas. The prototypes appear to have reached quite an advanced stage and have been shown in real-world road-testing.

While Sony announced in January that it would start a new unit called Sony Mobility which would handle commercialization of EVs, this move may well have been too challenging for the company which does not have experience in making cars. Honda, on the other hand, has been producing many fine cars with its decades of experience. As Sony would have vast experience in electronics, which are dominant in EVs, its expertise will be very useful.

So it remains to be seen whether Honda will adopt Sony’s concepts – called VISION-S – or come out with a new design. If they want to do a new design, they have less than 3 years to do so as the plan is to start sales of the first model from the new company in 2025.

A new brand name?

There is also a possibility that the new EVs will have separate branding rather than be sold as Honda or Sony products. This is because the agreement is for the new company ‘to plan, design, develop, and sell the EVs’. It is agreed that Honda will be responsible for manufacturing the first EV model at its own factory.

“The New Company will aim to stand at the forefront of innovation, evolution, and expansion of mobility around the world, by taking a broad and ambitious approach to creating value that exceeds the expectations and imagination of customers. We will do so by leveraging Honda’s cutting-edge technology and know-how in relation to the environment and safety, while aligning the technological assets of both companies. Although Sony and Honda are companies that share many historical and cultural similarities, our areas of technological expertise are very different. Therefore, I believe this alliance which brings together the strengths of our two companies offers great possibilities for the future of mobility,” said Toshihiro Mibe, Director, President, Representative Executive Officer & CEO of Honda Motor.