The French are known for coming out with quirky looking cars, describing their looks as avant garde styling. They’re also known for making clever little cars that are ideal for urban transport. Now, at the dawn of the company’s 101st year, it is introducing a compact new model that it calls a ‘non-conformist mobility object’.

The new Ami is said to be a breakthrough response to challenges of urban travel and environmental awareness. And in certain countries, a driving licence is not required to use one on public roads. This is because it is a voiture sans permis (car without license) which is a category of small low-speed vehicles in France.

Citroen has designed the Ami just as much for the young teenager without a driving licence, who wants to visit a friend’s house or go to sports or music lessons completely independently, as it is for an older couple who already have a main vehicle but who prefer to favour Ami’s compactness for their short errands.

It can be used for car-sharing or long-term rental from €19.99 (about RM93) per month. If a customer wants to own one, the price starts from €6,000 (about RM28,000).

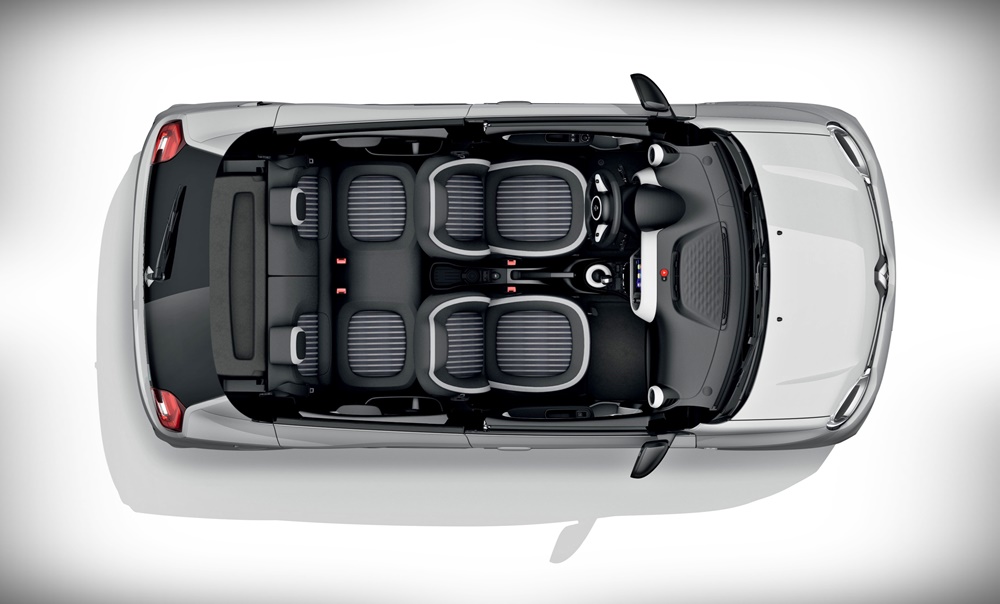

Car-like in external appearance and minimalist in concept, the Ami 2.41 metres long, 1.39 metres wide and 1.52 metres high) is essentially a more enclosed quadricycle with two seats next to each other.

To keep production costs low, as few unique parts as possible have been used. In fact, the front half uses the same body parts as the back. Front and rear bumpers, bumper undersides and underbody panels are mirrored at the front and rear.

The wide doors that are completely identical on the right and left and open in the opposite direction, rear-hinged on the driver’s side to benefit from better on-board accessibility and traditionally front-hinged on the passenger side. The side windows also follow this principle and like the 2CV, they open by manually tilting upwards. Besides the large amounts of glass all round (including a panoramic roof), the cabin also has a bright-coloured interior theme which gives the feeling of spaciousness.

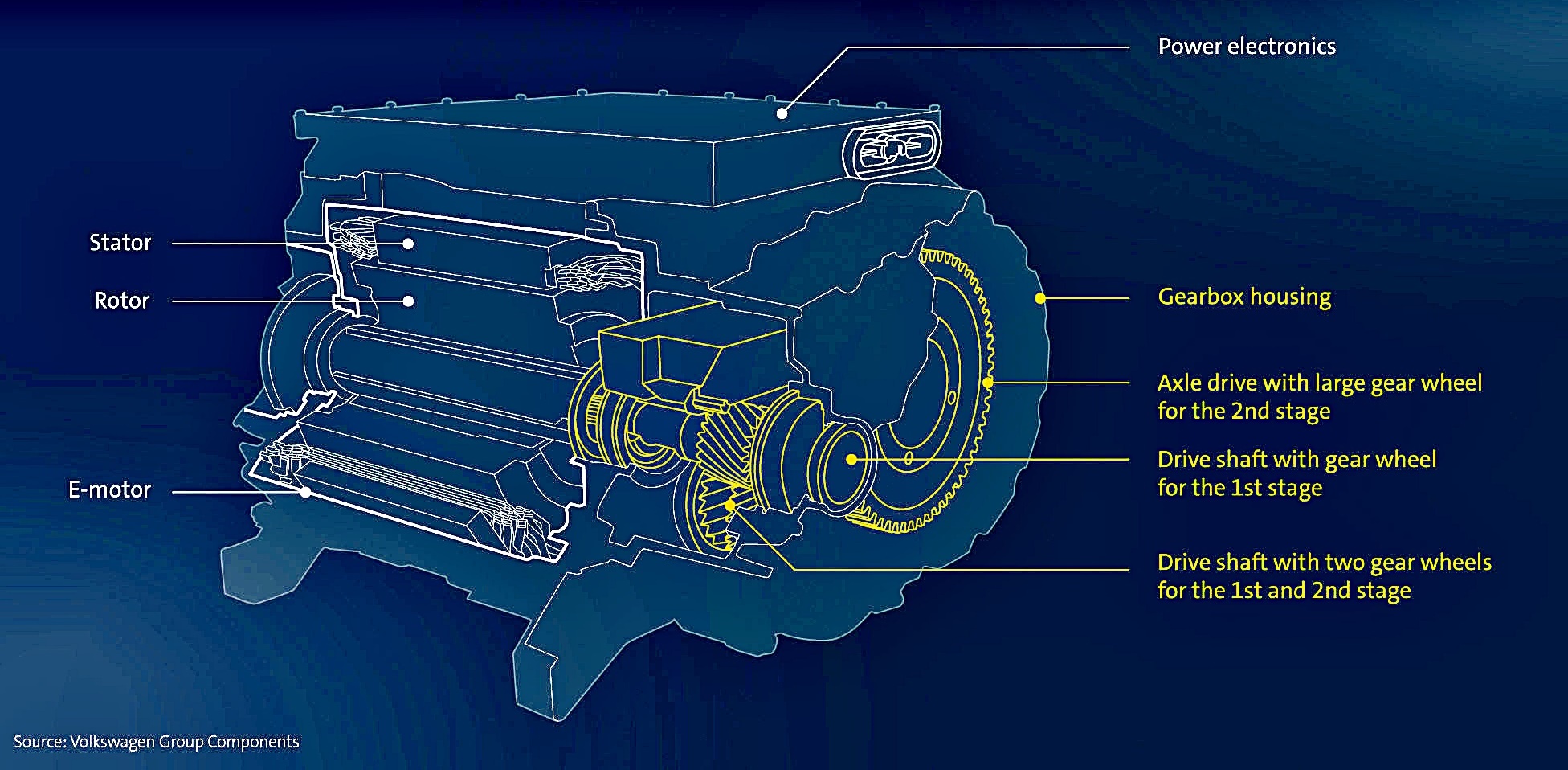

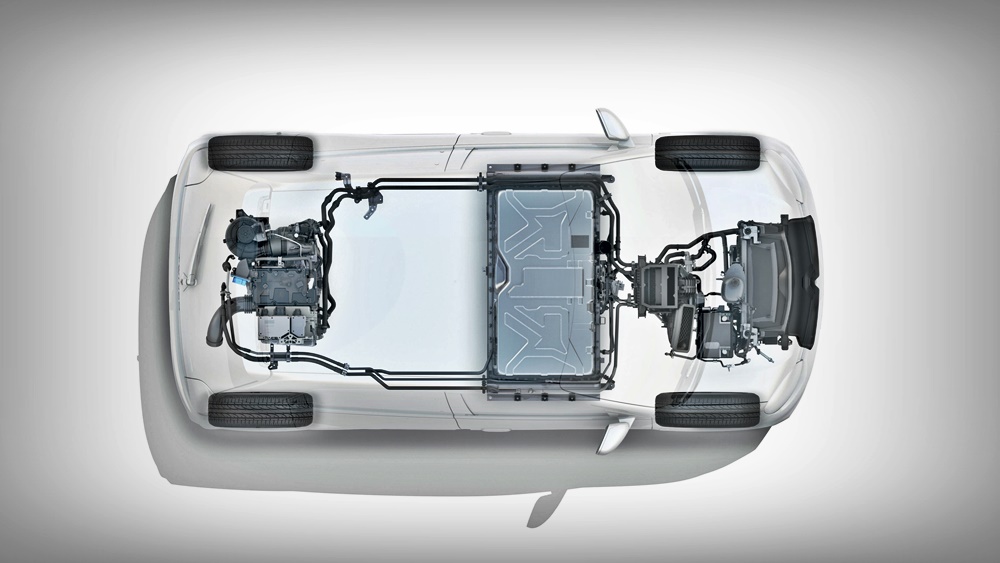

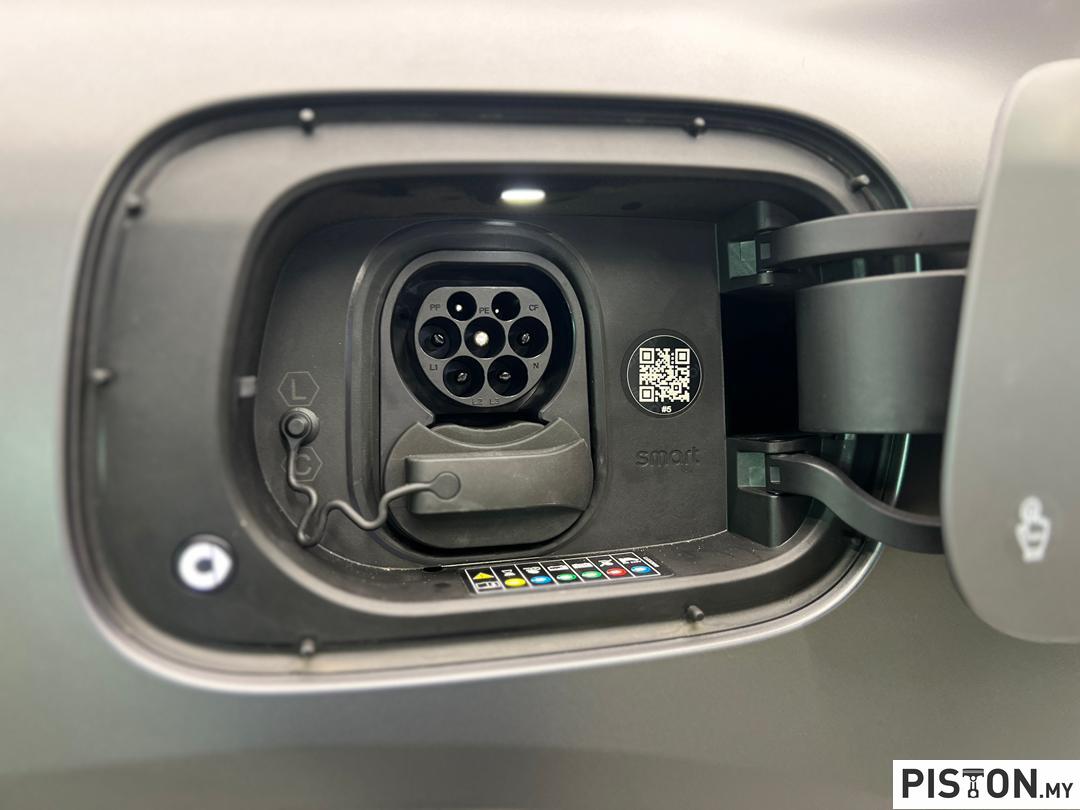

A small 6 kW (8 hp) electric motor drives the Ami which can reach a maximum speed of 45 km/h. This means it can’t be driven on motorways as there is a minimum vehicle speed requirement of 80 km/h. The 5.5-kWh lithium-ion battery provides a driving range of up to 70 kms, after which 3 hours will be needed to restore a full charge from a conventional 220V power socket.

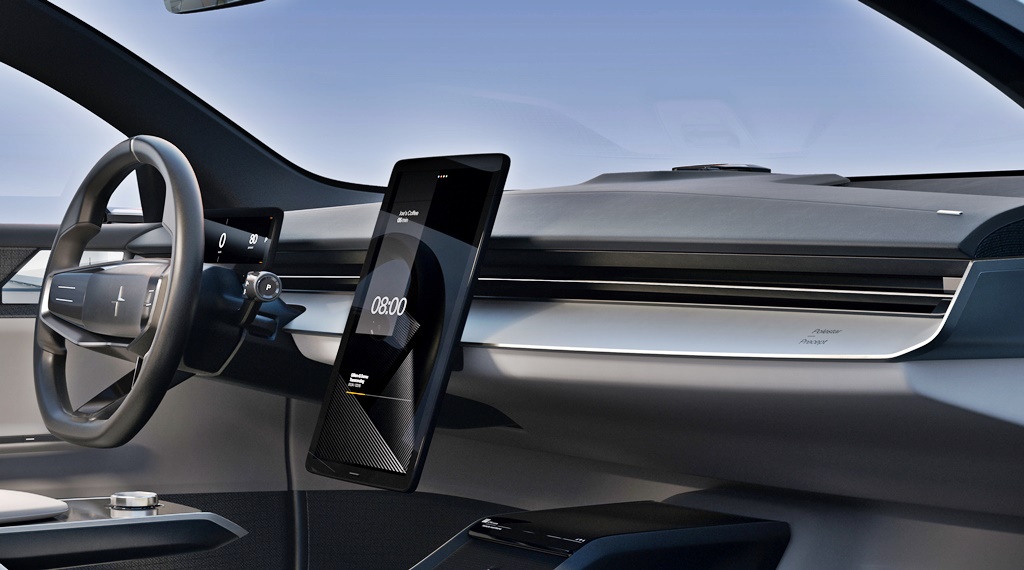

With the cabin having limited space, the items in the traditional dashboard are kept to a minimum. The instrument panel is basic and compact and information can be supplemented by using a smartphone placed in the middle of the dashboard. It links to the car’s systems via Citroen’s DAT@mi app and can show information such as range, charge status and time remaining for a 100% charge, mileage, maintenance alerts and after-sales appointment scheduling.

Every corner is exploited to its fullest for storage space. In addition to a storage recess at the passenger’s feet, which can fit a cabin-sized suitcase, the designers have also created another storage area at the rear.

EuroNCAP tested a few quadricycles some years back and found that their safety levels were rather low. Citroen doesn’t offer details of the passive safety of the Ami other than to say that it has a ‘level of protection greater than that offered by 2 or 3-wheeled vehicles’ and ‘its optimized footprint gives Ami stability and a great freedom of movement with no risk of fall’.

Easy to customise, the Ami is available in 7 different versions with customisation done through accessories. The accessories kit includes functional decorative items such as a central separation net, a door storage net, mat, storage tray on the top of the dashboard, and small hook for a handbag.

“Disruptive projects are always the best projects. These are usually the ones that really drive the automotive world forward, and it is a tradition at Citroen to want to contribute to changing this automotive landscape. The design of Ami is a product design, not an automotive design,” said Pierre Leclercq, Head of Citroen Style.