Mention Cadillac and most people outside the USA will have an image of a big, heavy, fuel-guzzling limousine. That’s what the cars of the 118-year old company looked like for decades, with the ultimate being ‘The Beast’ which is the nickname of the car used by the US President.

Like the other American carmakers, Cadillac was aware of the need to be indifferent to the issue of fuel consumption, especially after the energy crises of the 1970s. But it still had big engines that traditional customers liked, although new technologies helped make them fuel-efficient and new materials and engineering reduced weight.

But there’s a limit to how much an internal combustion engine can be improved, and manufacturers are now switching to electric motors that require no fossil fuel at all. Cadillac is readying for the transition. It has revealed its first all-electric vehicle (EV) as a concept model with the production version expected to go on sale in late 2022,

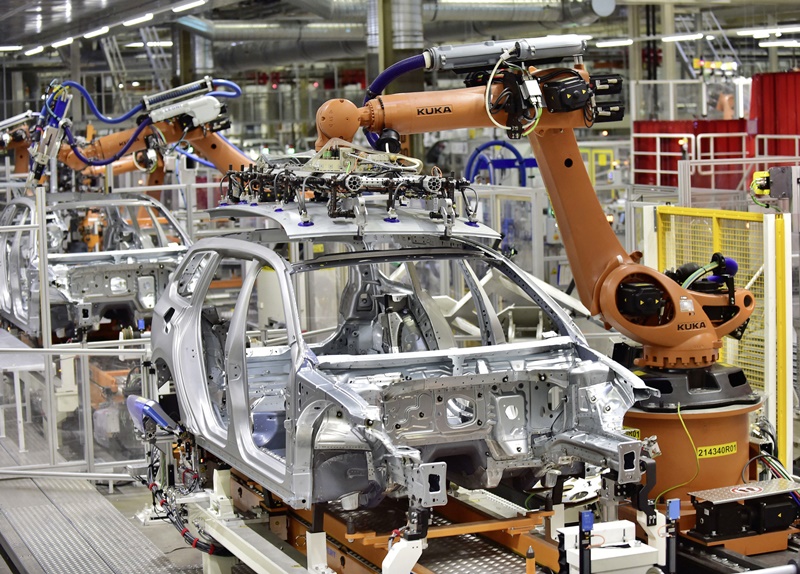

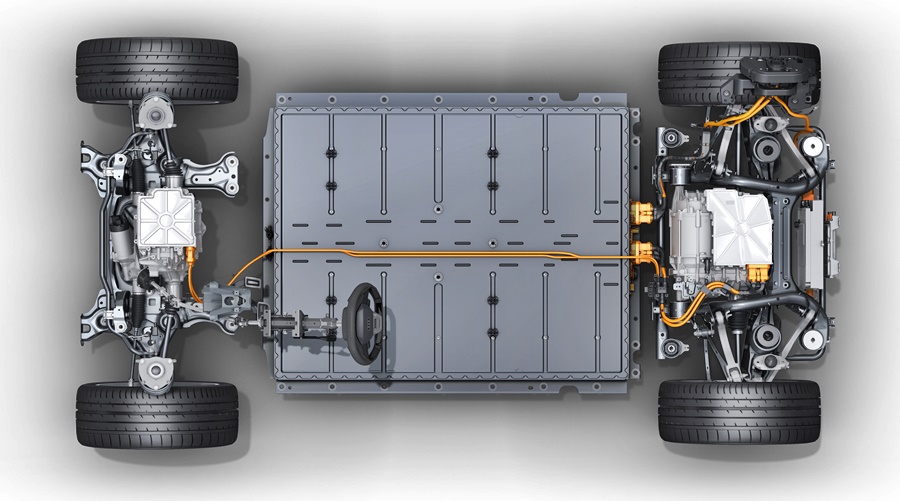

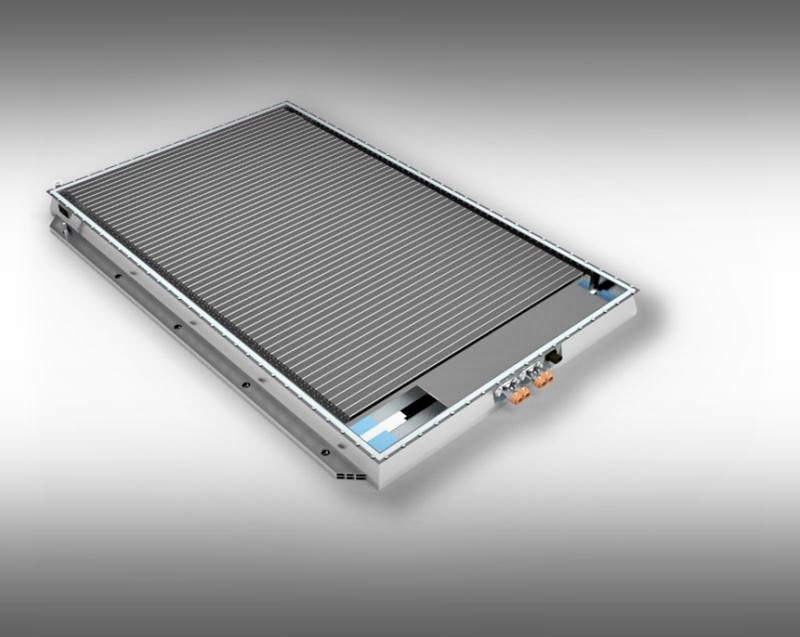

To use GM’s Ultium EV platform

Known as the LYRIQ, this is a crossover SUV based on GM’s next-generation, modular EV platform and driven by the Ultium propulsion system. With range being one of the biggest factors when it comes to selecting an EV, the target is 480 kms or more of range on a full charge. Charging options that fit a variety of preferences include DC fast-charging rates over 150 kW and Level 2 charging rates up to 19 kW.

The Ultium’s NCMA (nickel-cobalt-manganese-aluminium) chemistry uses aluminium in the cathode to help reduce the need for rare-earth materials such as cobalt. In fact, GM engineers reduced the cobalt content by more than 70%, compared to current GM batteries.

The advanced battery chemistry is packed in large, flat pouch cells that enable smart module construction to reduce complexity and simplify cooling needs. Additionally, the battery electronics are incorporated directly into the modules, eliminating nearly 90% of the battery pack wiring, compared to GM’s current electric vehicles.

Within the LYRIQ, the Ultium battery system is a structural element of the architecture, integrated in ways that contribute to ride and handling, as well as safety. In fact, the lower centre of gravity and near 50/50 weight distribution enabled by the placement of the battery pack provides benefits to handling.

Additionally, the LYRIQ is driven primarily by the rear wheels, with a performance all-wheel drive option available. The placement of the drive motor at the rear gives an even greater feeling of balance and agility. It also enables the system to channel more torque to the pavement without wheelspin for exhilarating acceleration and greater cornering capability.

Vehicles equipped with performance all-wheel drive go a step further, with a second drive unit placed at the front which allows for a significant amount of tuning flexibility, enhancing vehicle dynamics and performance.

New architecture, new possibilities

Inside, the LYRIQ’s new architecture opens up possibilities in spaciousness and design, encouraging the designers to rethink how to use the space and where to locate various interior elements. The more airy, minimalistic design does more to involve the driver and passengers in the driving experience while offering exceptional functionality when it comes to storage solutions.

The LYRIQ is said to offer Cadillac’s highest level of driver information, infotainment and connectivity integration. A 33-inch diagonal advanced LED display integrates a single, large screen that spans the viewing area for the driver and incorporates driver information details, infotainment controls and camera views.

This new display has the highest pixel density currently available in the automotive industry and can display over one billion colours. That’s 64 times more than any other vehicle in the industry.

A new dual-plane augmented reality-enhanced head-up display employs two planes: a near plane indicating speed, direction and more, and a far plane displaying transparent navigation signals and other important alerts.

Active noise cancellation technology

For the first time, Cadillac will introduce a new road noise cancellation technology, which takes active noise cancellation to the next level by introducing more microphones and accelerometers. With this new system, Cadillac’s performance and audio engineers can target the frequency range of tyre cavity noise, reducing the noise level in the vehicle and allowing for a quieter in-cabin experience.

The LYRIQ builds on the brand’s exclusive partnership with AKG. The objective was to deliver a sound experience that would transport the driver into a recording studio. The result is a 19-speaker AKG Studio audio system that delivers exceptionally crisp and precise sound reproduction.

“Led by LYRIQ, Cadillac will redefine American luxury over the next decade with a new portfolio of transformative EVs,” said Steve Carlisle, Executive Vice-President & President, GM North America. “We will deliver experiences that engage the senses, anticipate desires and enable our customers to go on extraordinary journeys.”

GM looking forward to all-electric future with Ultium batteries