When people started buying hybrids and electric vehicles, the issue of battery pack costs was not so apparent. Perhaps it was due to having used batteries in conventional cars which could last a few years and replaced periodically at a relatively low cost. However, the battery pack in an electrified vehicle (hybrid/EV) is different from the typical 12V battery in millions of vehicles. While the small battery in the engine bay provides electricity to start the engine primarily, the battery pack in an electrified vehicle actually powers the vehicle.

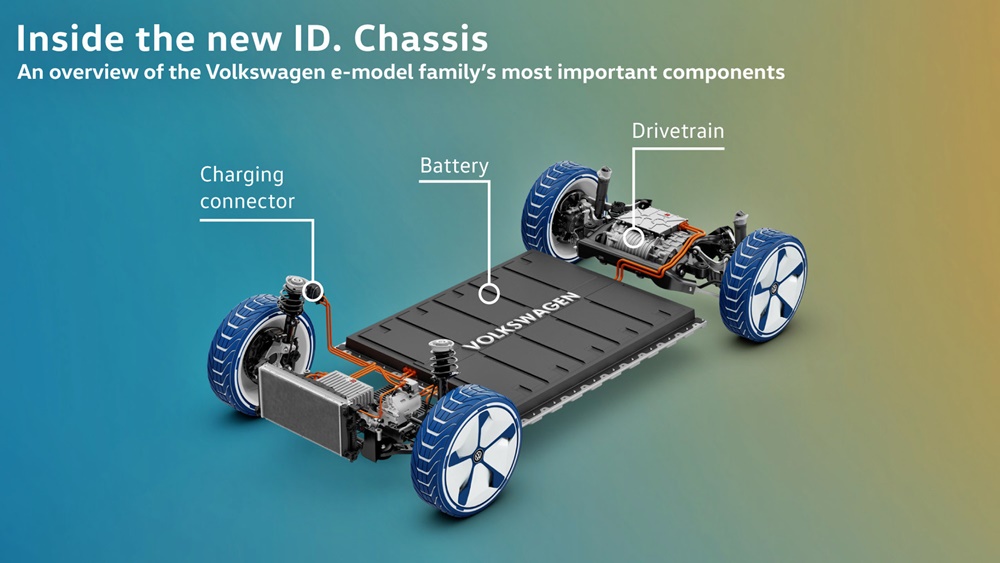

Due to the need to store large amounts of electrical energy, the battery packs have to be bigger and use more advanced technologies and materials. Conventional 12V batteries have typically used a lead-acid combination and though improved over the years, their process of generating electricity through chemical reaction has not changed.

Because battery pack technology is still evolving as storage capacity increases, the cost of the new technology is still high, not to mention the economies of scale are still lower than for conventional lead-acid batteries. This means they cost much more and for the early owners of electrified vehicles, there was the sudden shock of discovering that the cost of replacement was very high.

In Malaysia, depending on the model, the price was RM7,000 upwards. This led to reduced appeal for electrified vehicles and in order to provide peace of mind, the companies selling such vehicles began to offer a separate warranty on the battery pack which was longer than the factory warranty for the vehicle.

The prices have come down a bit and the battery pack for some Honda models sold in Malaysia is around RM5,500. Like those 12V batteries, the battery pack can last a while though there is no specific service life promised. Extreme operating conditions or rare system problems can shorten the life which is why the warranty is useful. But this does have an effect on resale value since the next owner would have to consider the added cost of replacement at some point in time.

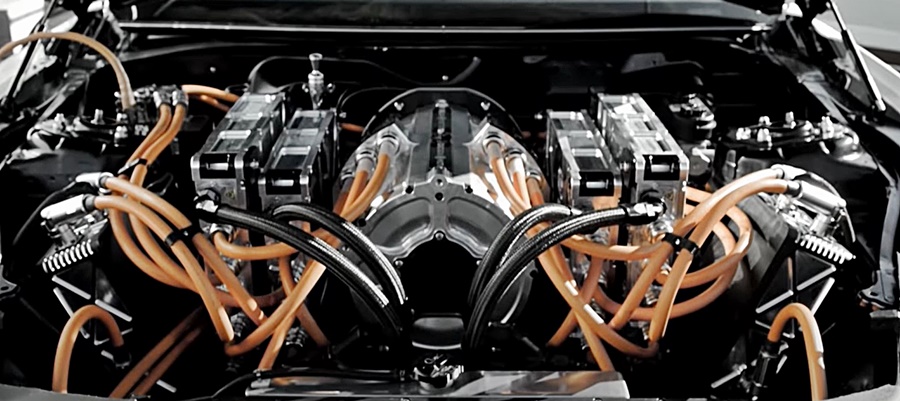

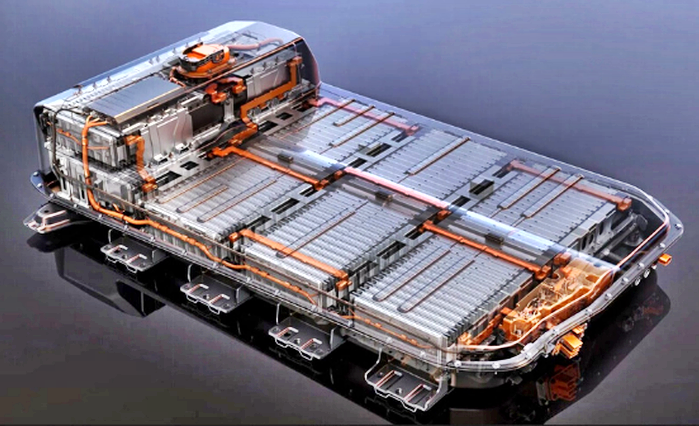

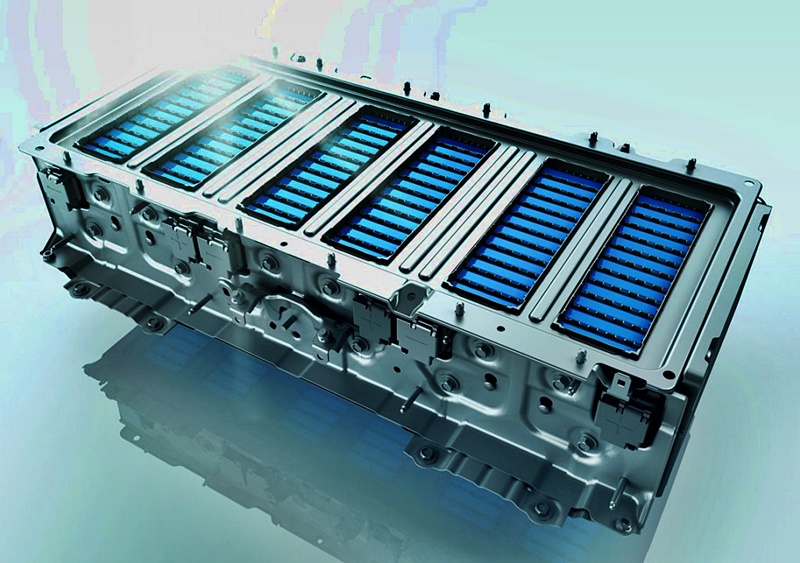

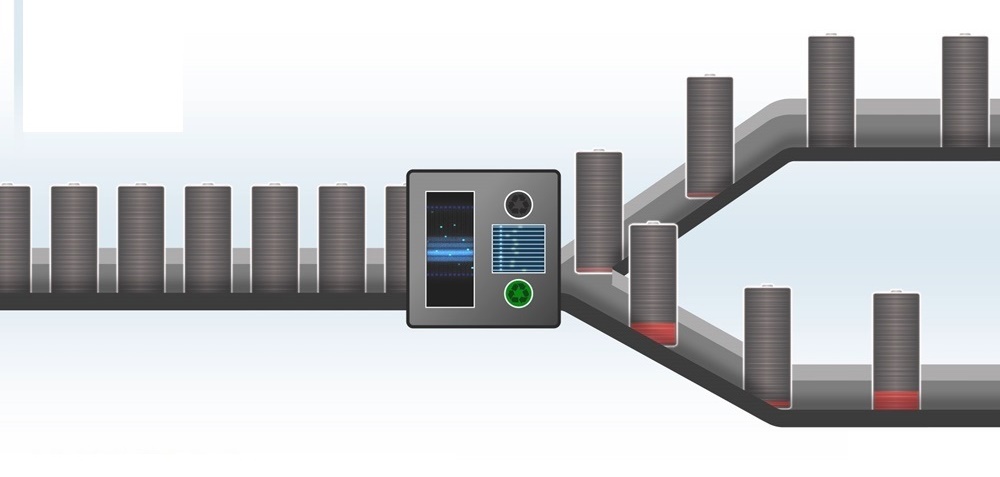

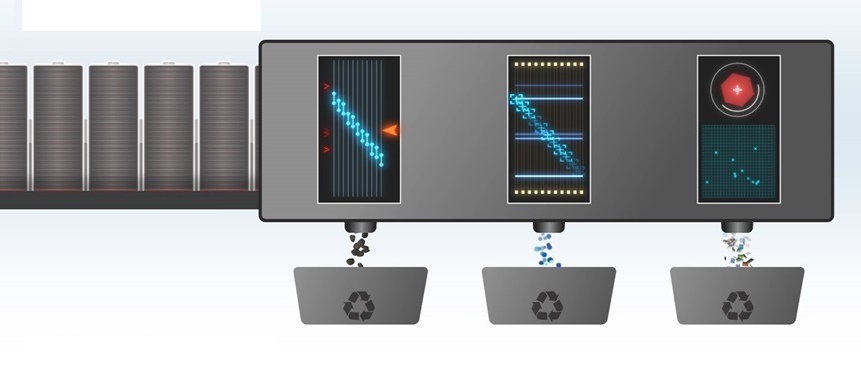

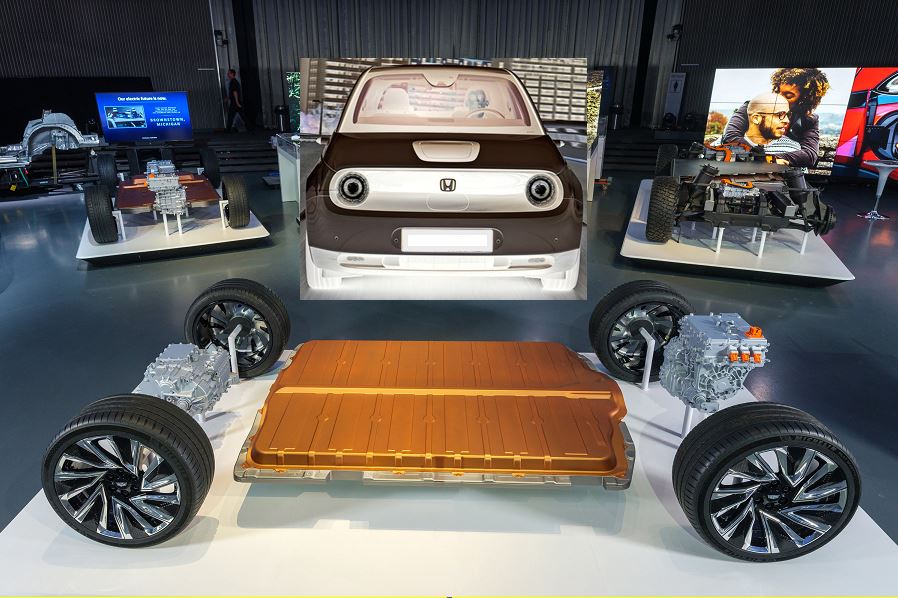

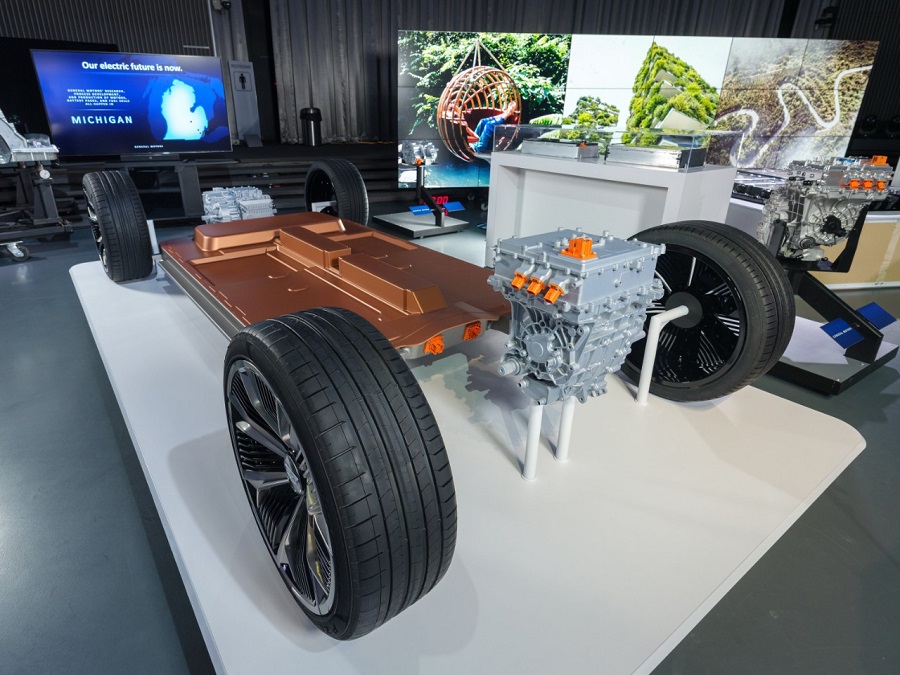

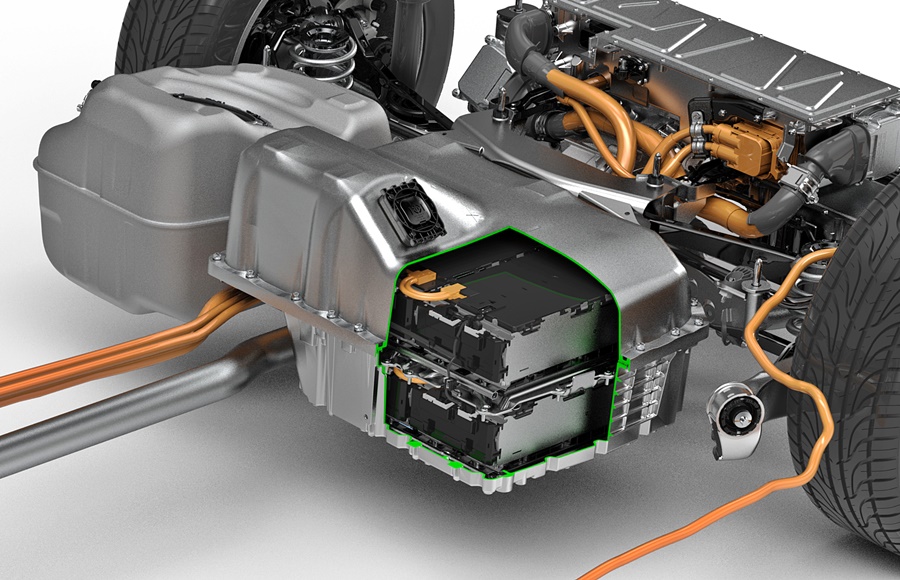

To address this key concern for electrified vehicle ownership, BMW’s high-voltage battery presents solutions to concerns around repair and maintenance by developing their batteries where single modules are replaceable. In the case of a lithium-ion battery pack (increasingly used) that houses multiple modules, there are multiple cells.

In most cases, if a battery pack starts to have problems or has reached the end of its service life, the whole unit has to be replaced – at considerable cost. However, the high-voltage battery pack used in BMWs does not necessarily require this expensive approach.

In the 530e M Sport, for example, the battery pack gas up to 6 cell modules. Should one of the modules be faulty, it does not mean the whole battery pack needs to be replace. Just that module can be changed and the cost is RM5,000 per cell. Although built to last the lifetime of the vehicle, BMW Group Malaysia still offers a comprehensive warranty coverage of 6 years/100,000 kms for the battery packs in its vehicles which should give peace of mind to owners.

The lightweight battery pack is capable of storing a great deal of energy, giving the 530e M Sport a maximum output of 83 kW which can get it to a maximum speed of 120 km/h in full electric driving. Recharging time is dependent on the type of system used but said to be under 3 hours with the BMW i Wallbox, with a fully charged battery pack giving an all-electric range of up to 40 kms.

BMW’s high-voltage battery technology is available in the plug-in hybrid variants of the 5-Series, 7-Series, as well as the all-electric i3s and the MINI Plug-In Hybrid.

Production of High-Voltage Batteries for BMW Hybrid Vehicles underway in Thailand