Valentine’s Day takes place in February and while it is regarded as a special occasion for couples, it is also a time when appreciation can be shown to those whom we care about. With this in mind, Edaran Tan Chong Motor (ETCM) is having a promotion with special offers on Nissan products as a way of showing its appreciation to customers.

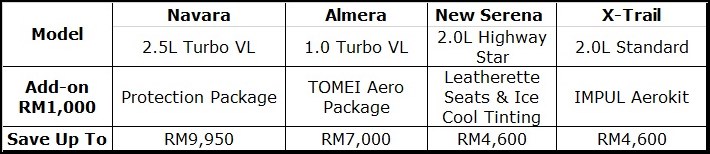

The promotion, called ‘Fall In Love At First Deal’ is for popular models such as the X-Trail and Serena. In the case of the X-Trail, there’s a new Black Edition accessories package which gives a bolder image with black-themed items. The package includes a Black Front Grille, Black TOMEI Aerokit, 17-inch Gloss Black Alloy Wheels, Brown NAPPA Combination Leather Seat with Leatherette Dashboard and Knee Pads, and Ice Cool Tinting.

(more…)