With electrification as a necessity for future products, McLaren Automotive has started an entirely new chapter in its history, and a new era in supercar technology and performance. The Artura, the first completely new model produced since the 12C, is McLaren’s first series-production High-Performance Hybrid supercar.

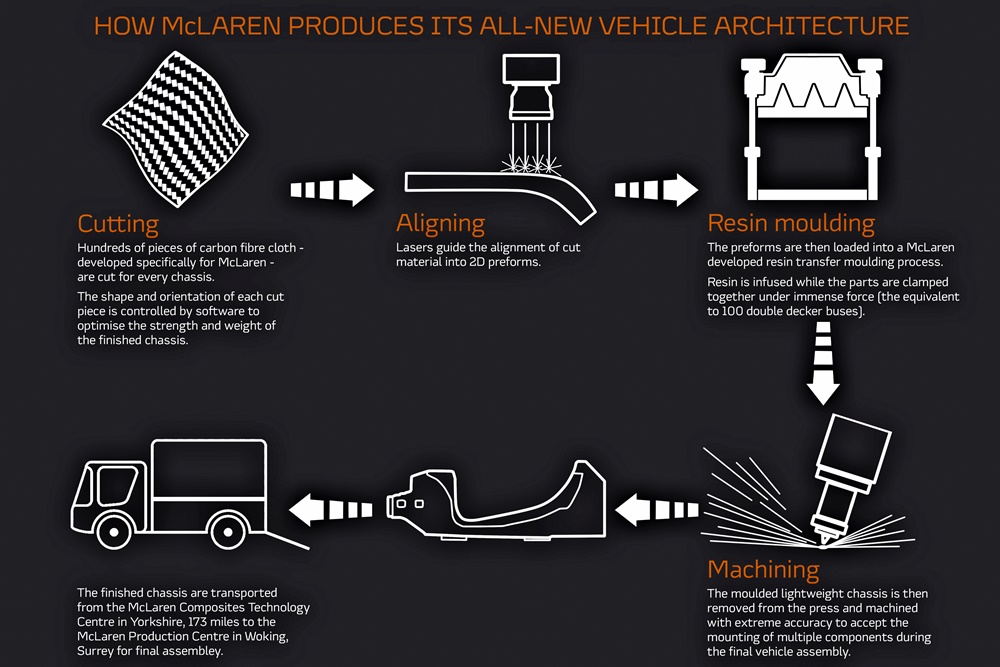

As with all other modern McLarens, super lightweight engineering is a key element and was a priority for the engineers as they considered the replacement of the conventional combustion engine with a hybrid powertrain which would include a heavy battery pack.

Opportunities to innovate

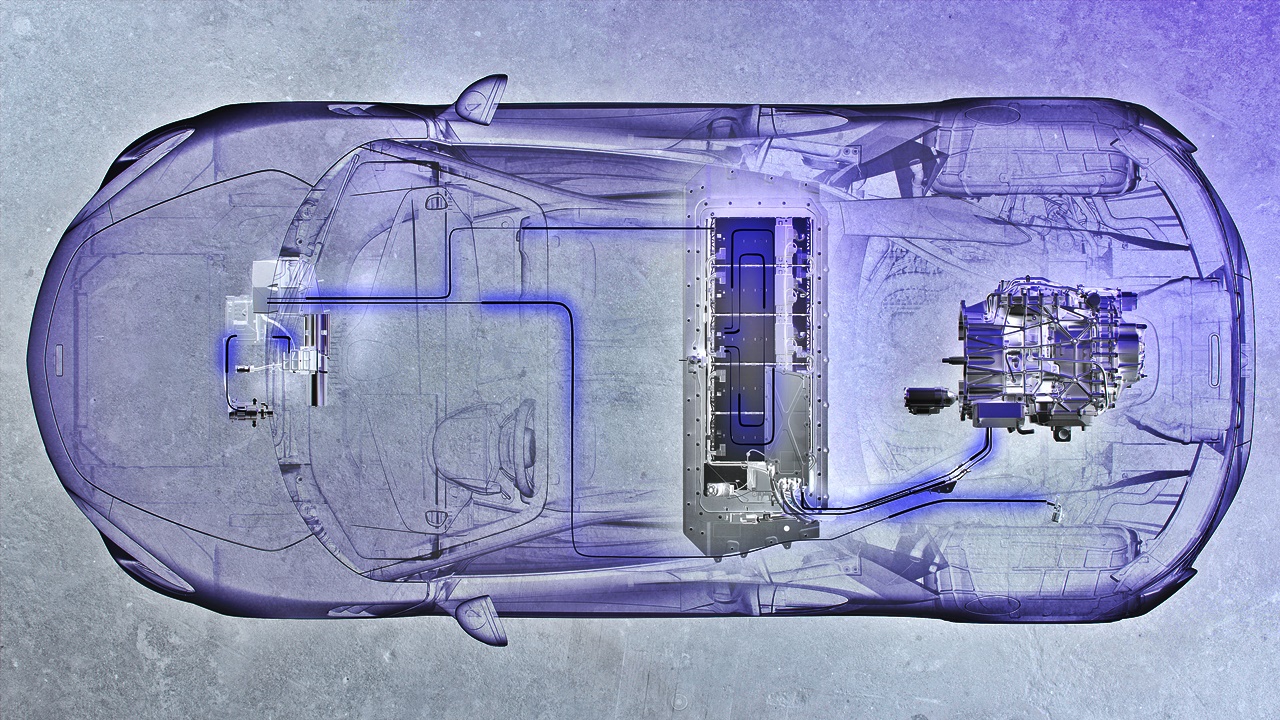

It was a challenge that presented McLaren’s engineers and designers with new opportunities to innovate. A demanding programme of weight reduction, encompassing every area of the Artura from the chassis platform to the uniquely compact HPH powertrain system, to the weight of cabling used in the electrical systems (where a 10% reduction was achieved), resulted in the Artura having a lightest dry weight of 1,395 kgs.

The total weight of hybrid components is just 130 kgs (including an 88kg battery pack and 15.4 kg E-motor), resulting in a kerb weight of 1,498 kgs. That’s on par with comparable supercars that do not have hybrid powertrains, giving the Artura a super-lightweight advantage.

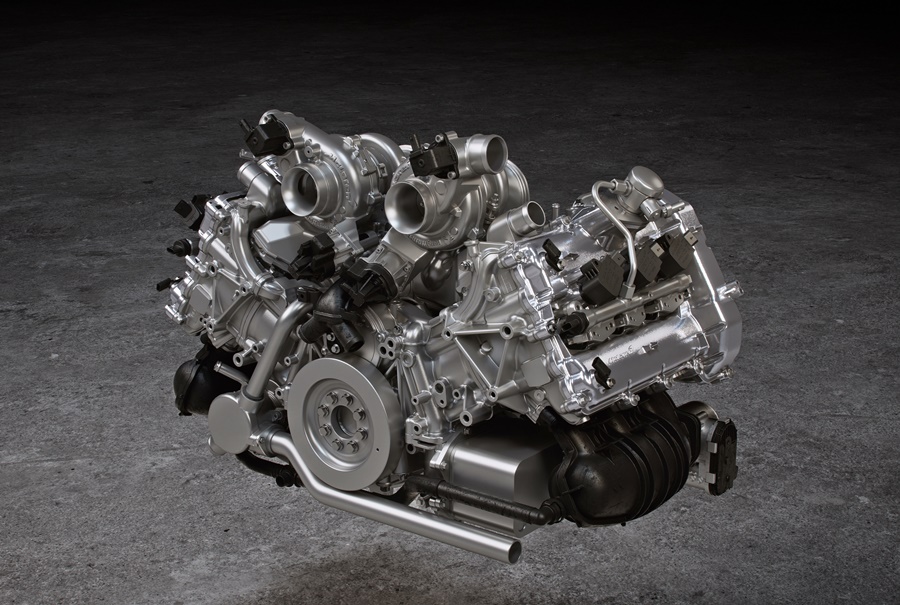

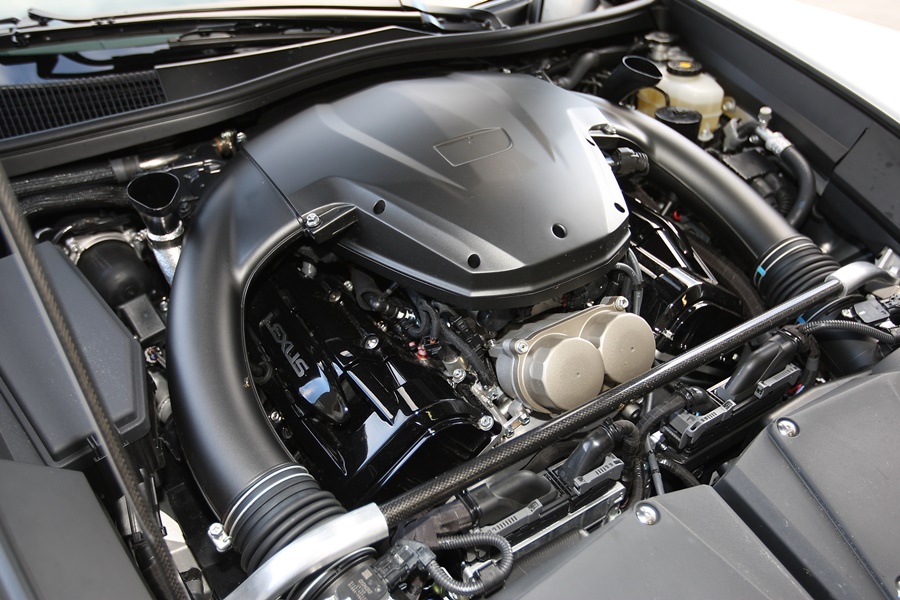

Twin turbo V6 + E-motor

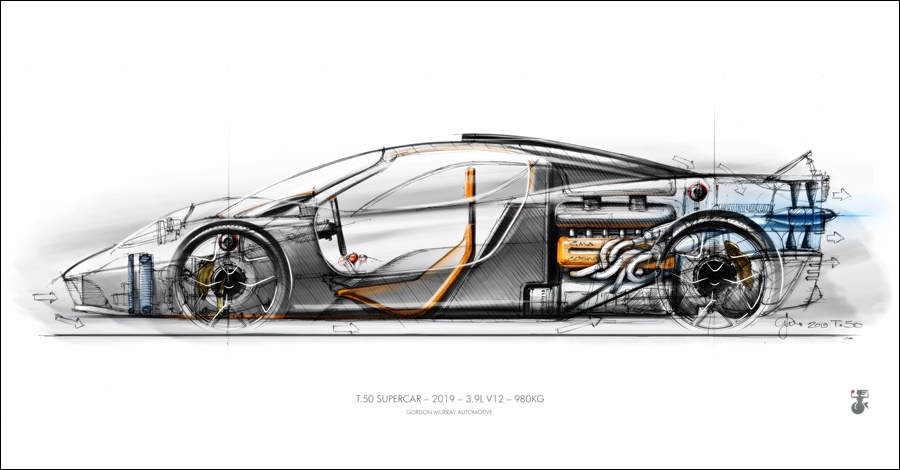

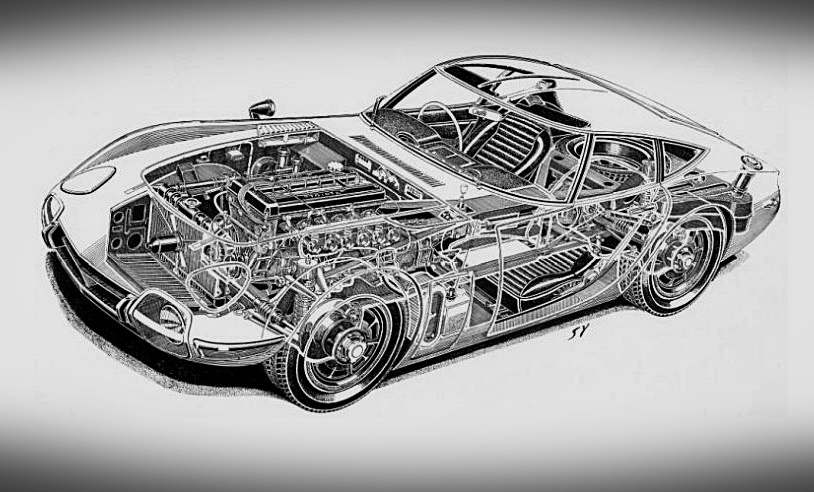

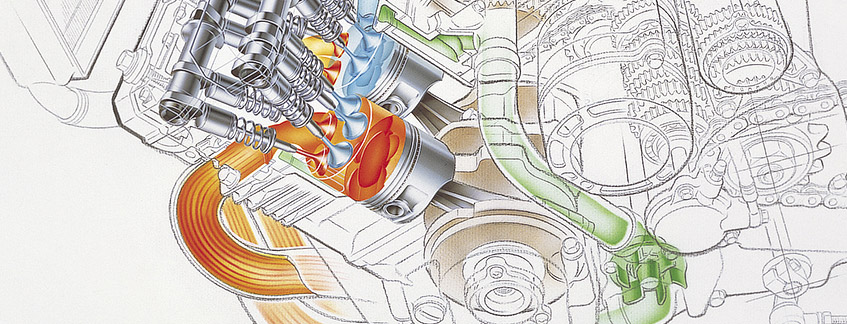

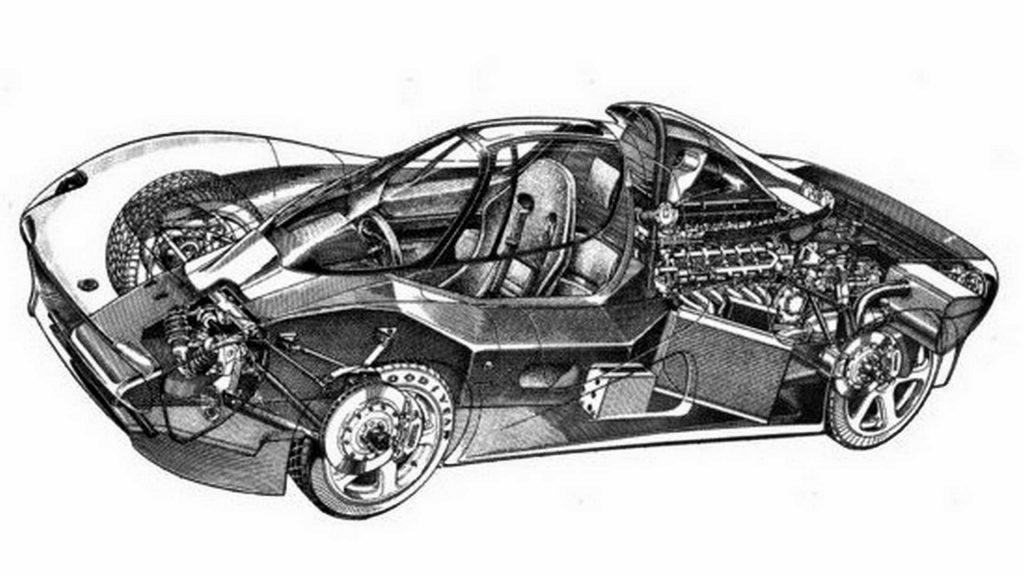

At the heart of the Artura’s powertrain is McLaren’s all-new M630 2993 cc twin-turbocharged V6 petrol engine. With a power output of 585 ps – nearly 200 ps per litre – and 585 Nm of torque, the dry-sump aluminium engine is compact and lightweight; at just 160 kgs, it weighs 50 kgs less than a McLaren V8 and is significantly shorter, enhancing packaging efficiency.

Working in harmony with the new V6 is a compact E-motor, located within the transmission bell housing. Small and more power-dense, it is capable of generating 95 ps and 225 Nm, boasting a power density per kilo that is 33% greater than the system used in the McLaren P1.

The instantaneous nature of the motor’s torque delivery – known as ‘torque infill’ – is key to the car’s razor-sharp throttle response. Exhilarating ‘off-the-line’ performance is promised with a claimed 0 – 100km/h time of 3 seconds, and a top speed somewhere beyond 330 km/h but limited to that speed.

No reverse gear

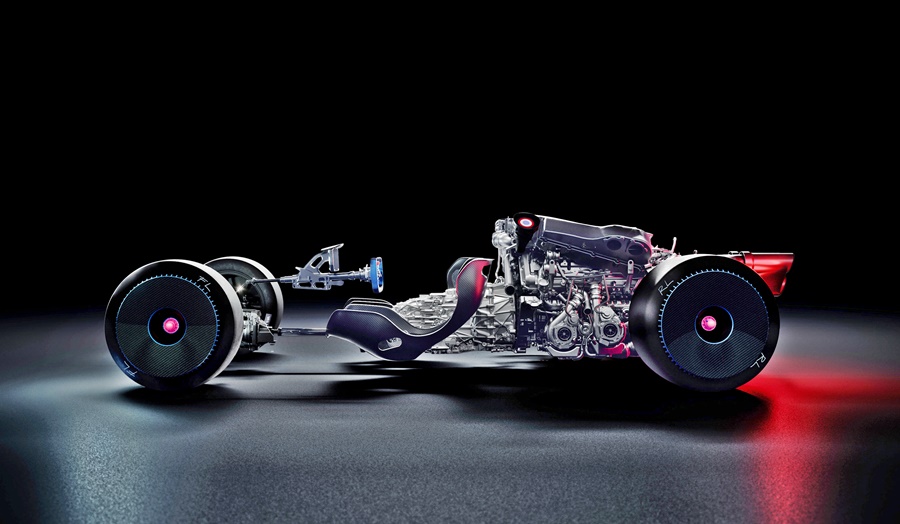

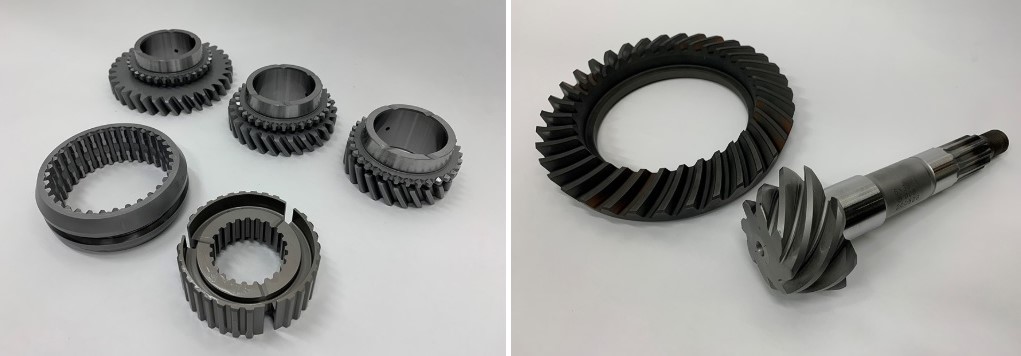

The dual propulsion systems are integrated via an engine disconnect clutch, driving an all-new, twin-clutch transmission, developed specifically for the Artura. Despite having one more ratio than the existing McLaren transmission – to optimise power and torque delivery – the lightweight, short-ratio gear cluster is 40 mm shorter in length. It also requires no reverse gear as the E-motor takes care of reversing by literally rotating in the opposite direction.

The driver can choose from four Powertrain modes for different driving conditions and preferences. There are Sport and Track modes where electric power is deployed in an increasingly aggressive manner for low-end response and acceleration. Separate handling mode choices adjust damper firmness and the degree of Electronic Stability Control intervention to suit driver preference and weather and road conditions.

30-km range in EV mode

The E-motor is powered by a lithium-ion battery pack with a usable energy capacity of 7.4 kWh and a pure EV range said to be up to 30 kms. The battery is refrigerant-cooled using cooling rails, and the assembly – including a power distribution unit which transfers battery power from the rear of the vehicle to the ancillaries in the front – is mounted on a structural carbonfibre floor. This assembly is then bolted onto the rear base of the monocoque, optimising stiffness, weight distribution and crash protection.

Full PHEV capability

The Artura is designed with full Plug-in Hybrid (PHEV) capability; the battery pack can be recharged to an 80% level in just 2.5 hours with a standard EVSE cable. The batteries can also harvest power from the combustion engine during driving, tailored to the driving mode selected.

The Artura is the first model to have the new McLaren Carbon Lightweight Architecture (MCLA) at its core, setting a new standard for the carmaker’s advanced flexible chassis design. Optimised for high-performance hybrid applications, it includes a bespoke battery compartment and introduces a ground-breaking domain-based ethernet electrical architecture, along with an electrical heating, ventilation and air-conditioning (eHVAC) system.

The ethernet architecture reduces cabling by up to 25% as well as speeds up data transmission. This also facilitates access to advanced driver-assistance systems (ADAS) including Intelligent Adaptive Cruise Control, Lane-Departure Warning, Auto High-Beam Assist and Road-Sign Recognition as well as Over-The-Air (OTA) software updates.

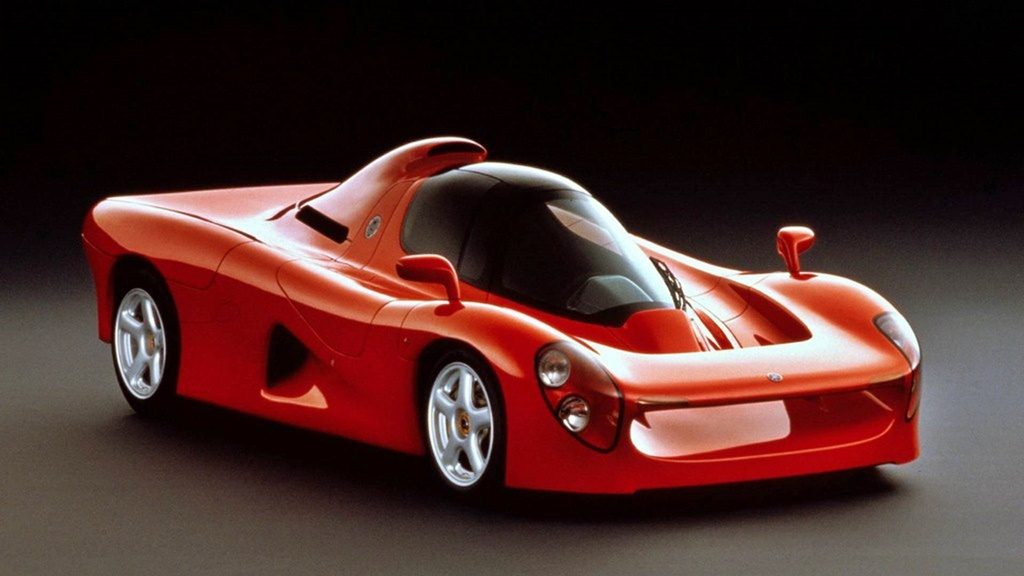

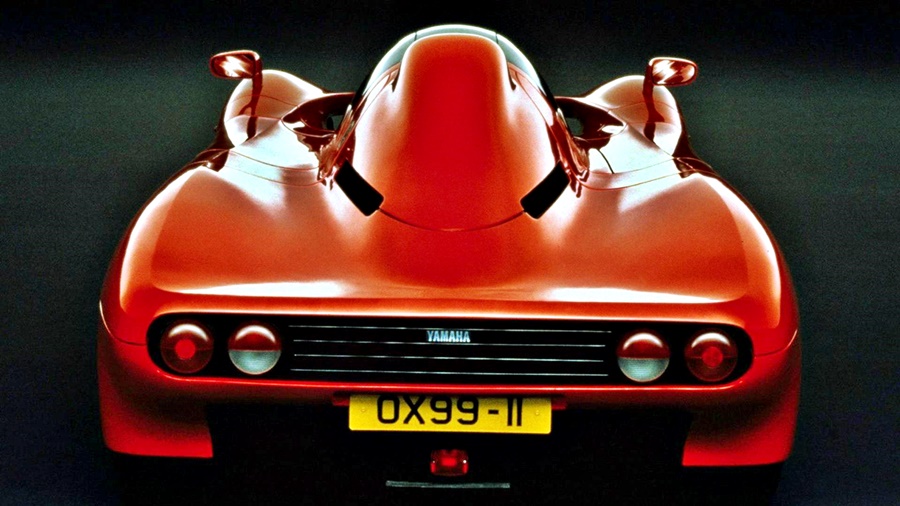

Pure supercar design

The engineering artistry beneath the Artura’s skin is complemented by its exterior design. The low-nose, cab-forward, high-tail stance is pure supercar, the drama underlined by the signature McLaren dihedral doors – which open closer to the body and house mirrors that fold in more tightly – and further enhanced by the short wheelbase and low stance.

The overall effect gives the Artura an almost ‘shrink-wrapped’ appearance, evolving a McLaren design approach seen in recent models to a new level. The lithe, technical sculpture has only minimal body shutlines and panel joints, assisted by features such as an entire rear clamshell engineered and superformed as one panel.

The shape, sculpted to optimise performance and manage airflow for aerodynamic performance and cooling, is driven by the McLaren design principle of ‘everything for a reason’ that is in evidence throughout the car. The centre of the front splitter is an example of this, being the intake for the eHVAC system and also housing the front-mounted radar that forms part of the optional ADAS package.

Driver-centric cockpit

Inside, the Artura is no less of a revolution, with the cockpit centred more than ever around the driver. The model introduces an all-new Clubsport seat, which uniquely combines the range of motion expected of a moveable backrest with the light weight and support of a bucket seat. Innovative yet uncomplicated, the whole seat pivots as one through an elliptical arc when adjusted, combining under-thigh support, seat height and backrest in one movement.

The seat locates in the ergonomically optimised cockpit, its carbonfibre shell combining with slim facia and doors to allow a 97.5th percentile (193 cm) driver to stretch out with generous knee and legroom, even with the backrest significantly reclined. Shoulder room is equally capacious, allowing a driver to get appropriately comfortable and seated correctly.

Driver and passenger comfort overall was an imperative throughout the development of the Artura, with NVH refinement high on the agenda. Innovations that benefit refinement include the stiffness of the MCLA, fluid-filled mounts for the powertrain and the new rear suspension design and settings. Pirelli’s patented Noise Cancelling System is also adopted to reduce vibration and noise.

More than a technological game-changer

At the outset, McLaren designed the Artura to be not only a technological game-changer, but also to stay true to the core McLaren attributes of being incredibly engaging to drive and displaying the highest levels of dynamic ability. The engineers focused on stability under braking; rear-end controllability; increased grip and optimised aerodynamic downforce – as well as enhanced driver engagement across the board. Key to hitting these goals is McLaren’s first-ever deployment of an electronically controlled differential (E-diff), to independently control torque moving across the rear axle. Lighter, more controllable and smaller than a mechanical locking diff (it fits within the transmission), the E-diff locks and unlocks individual rear wheels to improve traction out of corners.

The innovative rear suspension system, which pairs a top upper wishbone with two lower links and a tie rod in front of the wheel centre, maximises vehicle stability and precision, and reduces understeer out of a corner while accelerating. The wider tyres allow additional stability and better traction performance while the combination of a short wheelbase, E-diff and the physical downforce provided by the integrated rear spoiler and diffuser ensure both incredible agility at low speed and a high level of stability at high speed.

Pirelli Cyber Tyre

Dynamic precision is additionally enhanced by Pirelli Cyber Tyre technology. Comprising hardware and software integrated with the Artura’s electronic systems and featuring an electronic ‘chip’ inside each tyre, the Cyber Tyre generates real-time data and relays it to the car’s stability control systems to optimise tyre performance.

One feature that is unashamedly not new on the Artura is McLaren’s trademark hydraulically-assisted steering. Proven on generations of McLaren supercars, it remains the ultimate system for providing feedback. In the Artura, the system has been fully redesigned to reduce weight and is combined with an updated and bespoke version of McLaren’s Proactive Damping Control system that further supports exceptional ride and handling characteristics.

Braking performance is also exceptional, as would be expected of a supercar. This is provided by carbon ceramic brakes and lightweight aluminium calipers from the same family as the systems that feature in McLaren’s latest LT models.

“Every drop of McLaren’s experience and expertise has been poured into the Artura. Our all-new, High-Performance Hybrid delivers all of the performance, driver engagement and dynamic excellence for which McLaren is renowned, with the additional benefit of EV driving capability. The introduction of the Artura is a landmark moment – for McLaren, for our customers who will appreciate and enjoy this car on every emotional and rational level, and for the supercar world,” said Mike Flewitt, CEO of McLaren Automotive.

First deliveries to customers will start during the third quarter of 2021 with prices in the UK starting from £185,500 (about RM1.04 million). There will be 3 further core specifications for customers to choose from.