Though it has a variety of models, vehicles made in India have not have a significant impact on the world market. But that should change, thanks to Kia Motors which has today unveiled the Sonet, and the Korean brand’s made-in-India global product after the Seltos.

Manufactured at Kia’s state-of-the-art production facility at Anantapur, Andhra Pradesh, the Sonet is Kia’s latest all-new urban compact SUV., It marks the brand’s entry into the competitive and still growing compact SUV segment, with first-in-class features that are said to set new benchmarks.

The Sonet will be launched in India soon, followed by exports to many other markets around the world. Pricing ranges from Rs 8 lakh to Rs 13 lakh (about RM47,000 – RM73,000) in the domestic market.

Another tiger nose grille interpretation

The Sonet incorporates Kia’s DNA of emotive styling, displaying a dynamic stance in a compact body. Up front, a fresh interpretation of Kia’s signature ‘tiger-nose’ mesh grille pays respects to India’s historic strengths in sophisticated mathematics, science and architecture. The 3-dimensional geometric design inspired by India’s iconic stepwells.

It is flanked by ‘heartbeat’ LED DRLs (daytime running lights). Shaped like the electric pulse of a heart, the theme is also used for the rear lighting units. A stylish front skidplate contributes to the rugged image while the silhouette incorporates a unique design and structure for the C-pillar, matched with a wraparound rear windscreen.

Compact outside, ergonomic inside

Inside, the Sonet is designed around the driver, with a well laid-out, easy-to-use connected infotainment and cluster interface. Despite compact exterior dimensions, the interior of the Sonet offers ample space for all passengers with ergonomic considerations met.

To suit a wide array of customers, the Sonet will be offered in a dual trim concept. This will include the sporty GT-Line trim for enthusiasts. GT-Line models are finished with contrast red stitching on the steering wheel, seats and door armrest, with a D-cut steering wheel for the driver.

The dashboard has the largest-in-segment 10.25-inch HD touchscreen with infotainment and navigation system which uses Kia’s connected car technology. Additionally, the 4.2-inch instrument cluster presents important information to the driver in vivid colour and clarity, such as turn-by-turn navigation instructions, tyre pressure, drive mode and traction mode selection.

To create a concert-like ambience, the Sonet is the only vehicle in its category to offer audio performance from BOSE, with a 7-speaker system. Other mood enhancers include the LED Sound Mood Lighting, introducing a level of personalisation unique to this segment, as well as a wireless smartphone charger with cooling function. The two front seats are ventilated, which should be a welcome feature in hot climates.

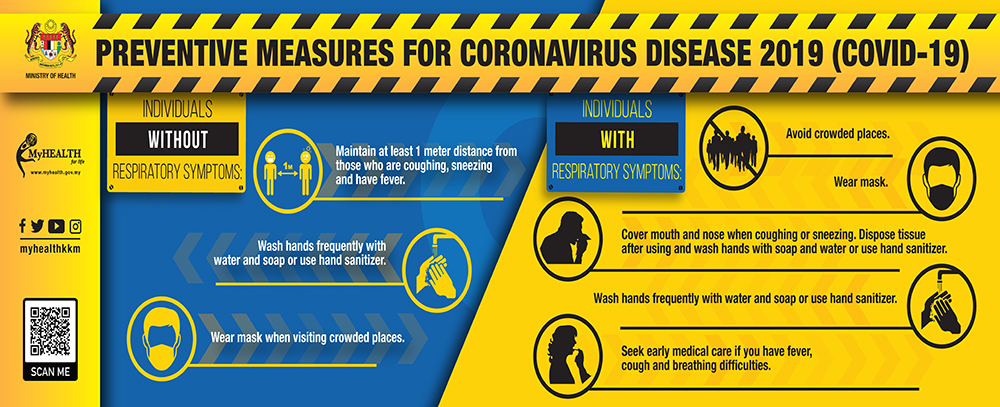

Important for these times is Kia’s Smart Pure Air Purifier with virus protection. This is a 2-level purification system with a pollutant-cleansing HEPA N29 filter. The filter uses fibre made from nano-ionic bonding technology of copper sulphide, effective in removing pollutants and bacteria from the cabin air. The second level of filtration is achieved with a UV-C LED beam, UV rays having been proven to kill bacteria.

Multiple powertrain options

The Sonet will be offered with multiple powertrain options to suit different markets. There’s a choice of two petrol engines – a Smartstream 1.2-litre 4-cylinder unit and a 1.0 T-GDi (turbocharged gasoline direct injection) – as well as an efficient 1.5-litre CRDi turbodiesel engine.

Customers will be able to choose from up to 5 transmission types (depending on market) – 5 and 6-speed manuals, a 7-speed DCT, 6-speed automatic, and Kia’s revolutionary new 6-speed Smartstream intelligent manual transmission (iMT). The iMT is said to be a technological breakthrough from Kia, offering fatigue-free driving by omitting a clutch pedal. For the first time in this segment, the Sonet also offers a 1.5-litre turbodiesel engine with the 6-speed automatic transmission.

The ride and handling have been tuned by Kia engineers at the brand’s Namyang R&D headquarters in Korea as well as at the brand’s Development Centre at Anantapur. Sonet prototypes have been driven and tested for over 100,000 kilometres on Indian roads, across a variety of conditions, to confirm durability and reliability.

Aiming at millennials and Gen Z

“Kia Motors continues to be recognised globally through products which offer exquisite design and world-class quality, along with ‘The Power to Surprise’. Everything about the all-new Sonet is uniquely Kia and is sure to delight both drivers and passengers,” said Ho Sung Song, President & CEO of Kia Motors Corporation.

“With its aggressive and modern design language, fun-to-drive dynamics, and Kia’s latest high-tech features, the Sonet puts an exclamation point on our ambition to make Kia the brand of choice, especially among millennial and Gen Z consumers. The Sonet fills a need in the growing SUV market, in India and further afield, and will attract a wider number of consumers to the Kia brand,” he said with confidence.

Hyundai and Kia vehicles will have cleaner air in cabins in future (w/VIDEO)