It may seem like a fun job being a test-driver in a car company, driving prototypes of new models long before they are revealed to the world. While there may be some element of enjoyment at certain times, the work of a test-driver is largely planned and precisely run to verify performance as well as test many different parts and systems in a variety of conditions.

Every new vehicle must go through such demanding test programs and depending on the model, it might be in different parts of the world. The BMW i7, for example, is now entering its final phase of development work and is being tested in extreme road and weather conditions. It will be launched later this year, along with the new 7-Series.

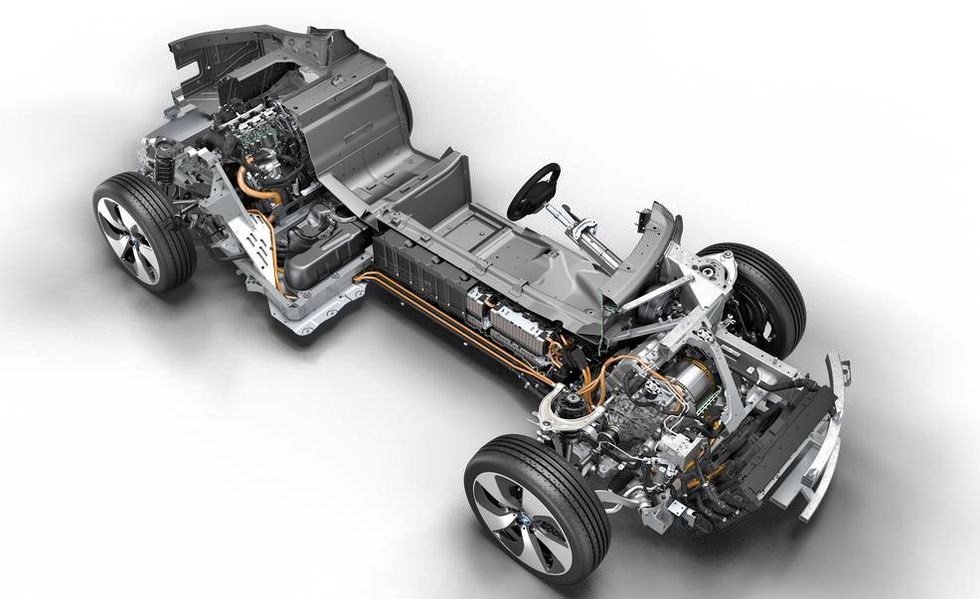

During so-called hot-region testing on tracks and public roads all over the world, the development engineers primarily verify the performance and reliability of the electric motors, the all-wheel drive and the high-voltage battery when being exposed to maximum stress from high temperatures, unpaved roads, dust and large differences in altitude. They will travel over gravel tracks into deserts, into the mountains and on a whole series of highly dynamic routes, besides BMW’s own test courses.

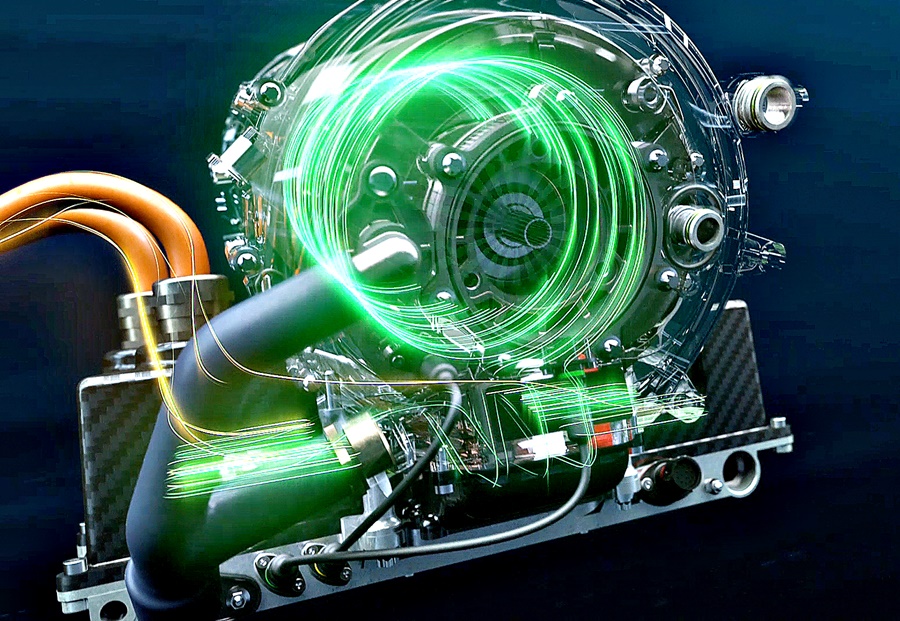

The endurance test in the hot regions of various countries and continents serves in particular to test and safeguard all components of the electric drive system. The components of the fifth-generation BMW eDrive technology developed for the i7 demonstrate their unrestricted functionality – even under the most adverse conditions when being used continuously in extremely high outside temperatures, permanent sunlight and dry conditions.

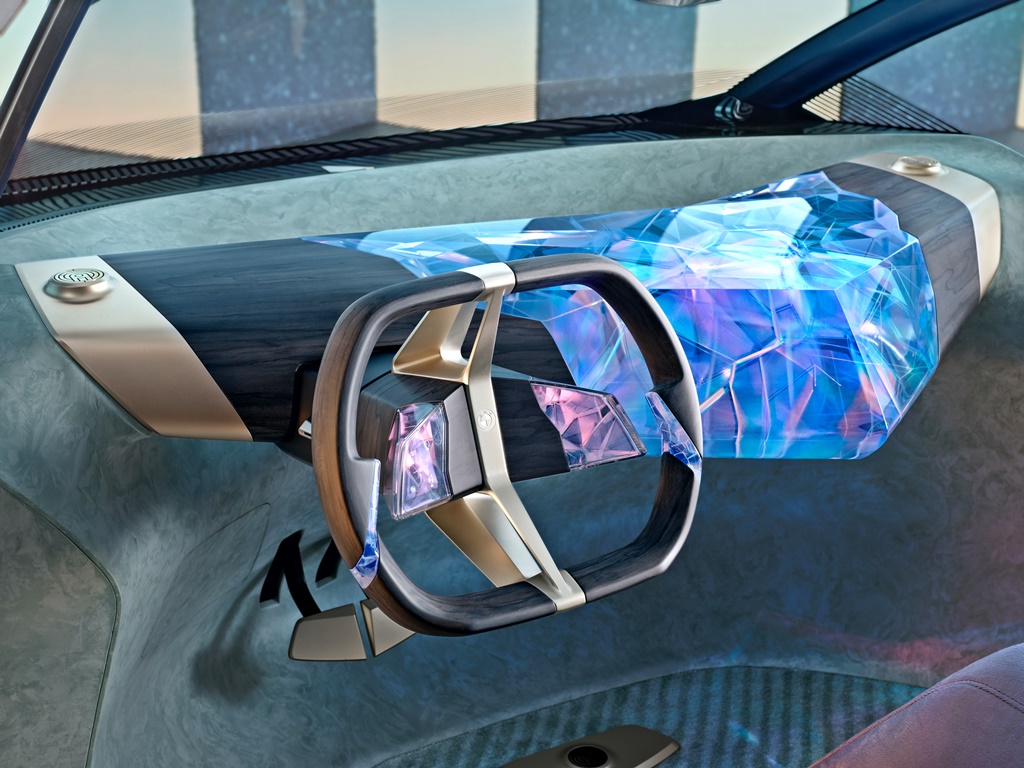

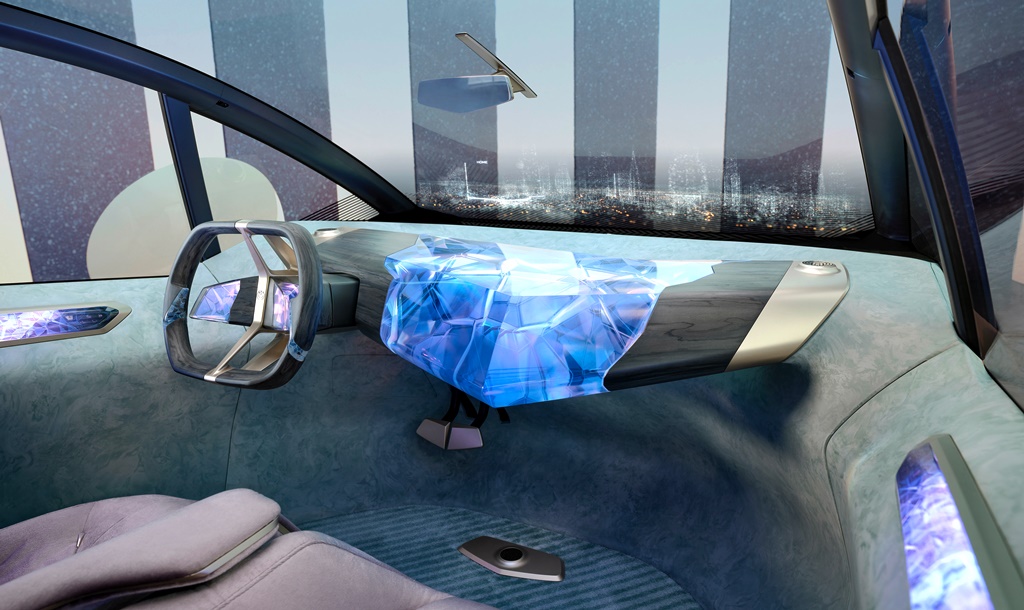

Within a firmly defined test programme for the prototypes, loads are simulated that correspond to the challenges faced by a series-production vehicle during a complete product life-cycle. Supported by sensitive on-board measurement technology, experienced test engineers register every reaction of the electric motors, the high-voltage battery, drive control and the integrated cooling system as well as the charging technology and energy management to weather and road-related influences.

The testing programme, which covers tens of thousands of kilometres, includes long-distance and high-speed driving as well as stop-and-go traffic in high temperatures. In addition, test sections with particularly large differences in altitude were selected at the hot-region test sites. In this way the temperature behaviour of the electric motors and the torque control of the all-electric BMW xDrive can be analysed during a particularly dynamic and long-lasting uphill drive.

To further increase the load on the drive system, the test programme also includes mountain driving in trailer mode. At the same time, the high-voltage battery shows how it able to continuously deliver peak power to supply the e-motors. As an extreme scenario and a particular challenge for energy management and power electronics, the test also involves driving downhill with a high-voltage storage system that is already fully charged at the start and can therefore no longer absorb any recuperation energy.

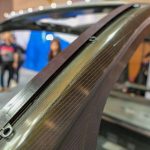

The gruelling hot-region test procedure is also used to put the performance of the air-conditioning and other on-board electronics, as well as the temperature resistance of the materials used in the interior, to a particularly tough test. This is all to ensure that the world’s only purely electrically powered luxury sedan will delivers reliable performance in any situation, anywhere in the world.

BMW Group Malaysia moves into next phase of electrification with new BMW i model range