Since May this year, a special Toyota Corolla Sport run by the ROOKIE Racing arm of TOYOTA GAZOO Racing has been competing in the Super Taikyu Series 2021. Its engine doesn’t run on petrol but uniquely, on hydrogen. This is not the same as the powertrain in the Mirai EV which has its electric motors powered by a hydrogen fuel cell. For the engine in the Corolla Sport, a prototype, the combustion process uses hydrogen.

Combustion in a hydrogen-fuelled engine occurs at a faster rate than in petrol engines, resulting in a characteristic of good responsiveness. While having excellent environmental performance, hydrogen engines still have the typical character of a combustion engine, especially ‘familiar’ sounds and vibrations. Except for the combustion of minute amounts of engine oil during driving, which is also the case with petrol engines, hydrogen engines emit zero CO2 when in use.

Moving to the next steps

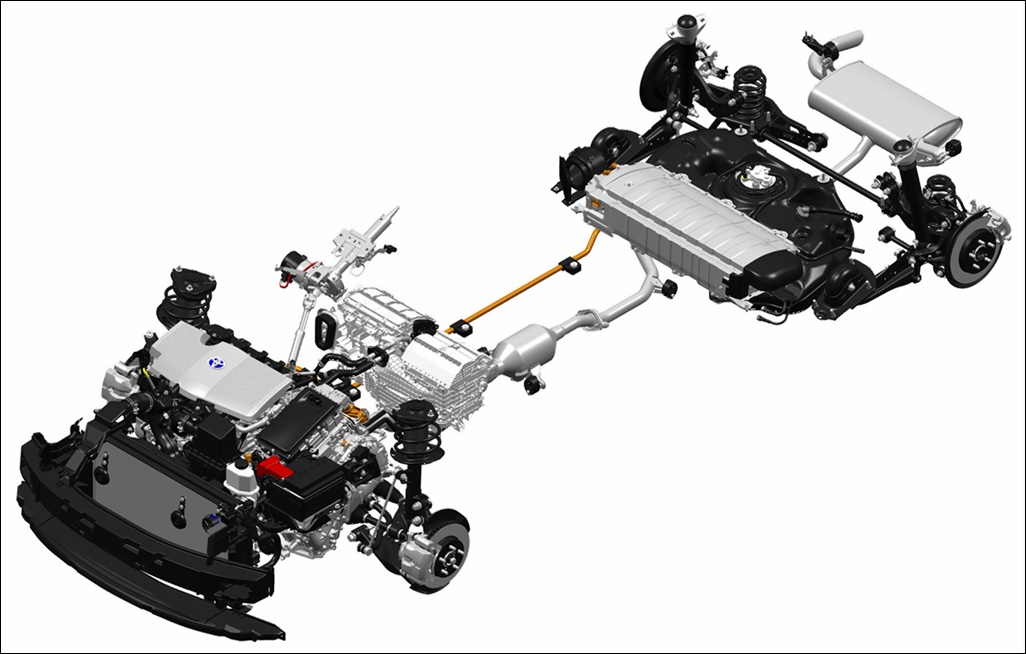

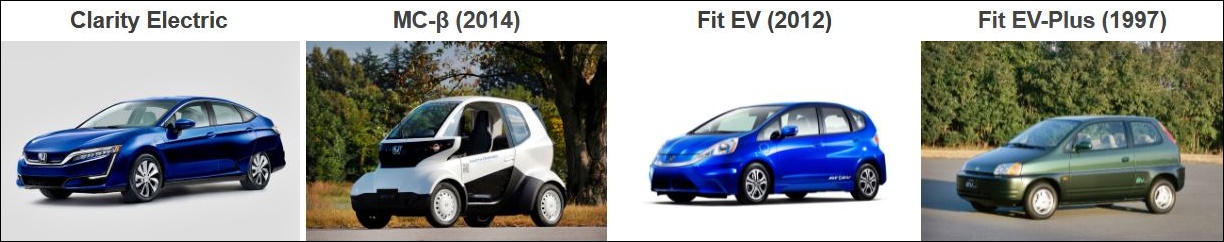

As the R&D engineers gain increasing experience and feedback from running the engine in the harsh conditions of motorsport in Japan, they are progressing towards the next steps. This is demonstrated in an experimental hydrogen-powered GR Yaris which shares same powertrain as the prototype Corolla Sport racing car.

The car’s hydrogen fuel, fuel tanks and refuelling process are the same as those found in Mirai fuel cell electric vehicle (FCEV) which is now in its second generation. The hydrogen combustion engine technology is still in the early stages of conceptual development and experimentation, having started in 2017, and is not yet ready for commercialisation. Nonetheless, Toyota’s experimental hydrogen-powered Corolla Sport is already delivering high performance at motorsport events in Japan with almost zero tailpipe emissions.

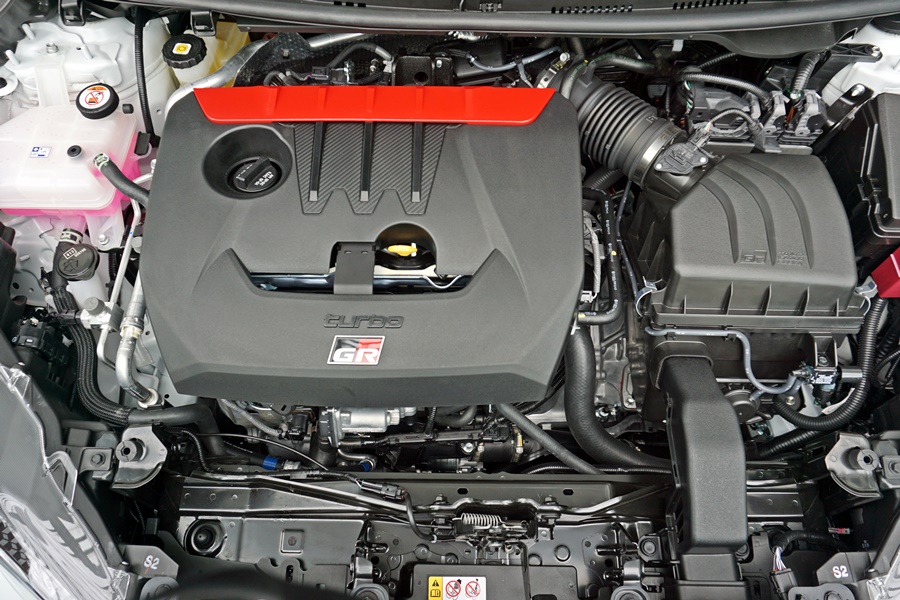

Modified GR Yaris engine

The engine modified to run on hydrogen is the G16E-GTS, 1.6-litre, in-line 3-cylinder, turbocharged unit used in production versions of the GR Yaris, but with a modified fuel supply and injection system for use with hydrogen as fuel.

Toyota has been strengthening its efforts towards achieving carbon neutrality, such as by aiming to promote the use of hydrogen through the popularisation of FCEVs and numerous other fuel-cell-powered products. By further refining its hydrogen engine technologies through motorsports, it intends to aim for the realisation of an even better hydrogen-based society.

Motorsport as a testing ground

The uses of motorsport as a testing ground reflects the firm belief of Kiichiro Toyoda, the founder of Toyota Motor Corporation, that sporting competition is a driver for progress. In March 1952, he said: “Japan’s auto industry must succeed in building passenger vehicles. To this end, manufacturers must participate in auto-racing to test their vehicles’ durability and performance and display their utmost performance. With competition comes progress, as well as excitement among motoring fans. The aim of racing is not just to satisfy our curiosity, but rather to enable the development of the Japanese passenger vehicle industry.”

“We’ve taken the first step to compete with and develop our hydrogen-powered engine with the mindset of taking on the challenge. I imagine things will look a little different 10 years from now, and I hope people will look back and see how we took on the challenge with positivity and enjoyed every moment of it,” added Akio Toyoda, President of Toyota Motor Corporation as well as grandson of Kiichiro.

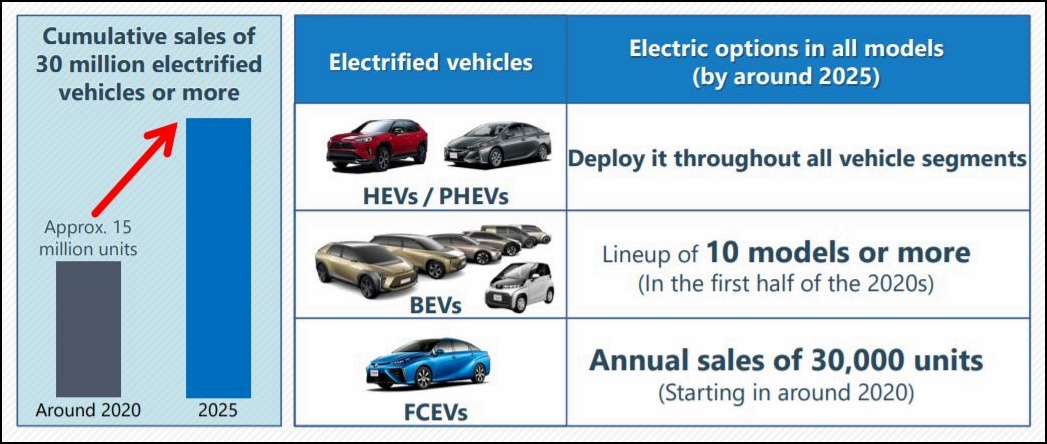

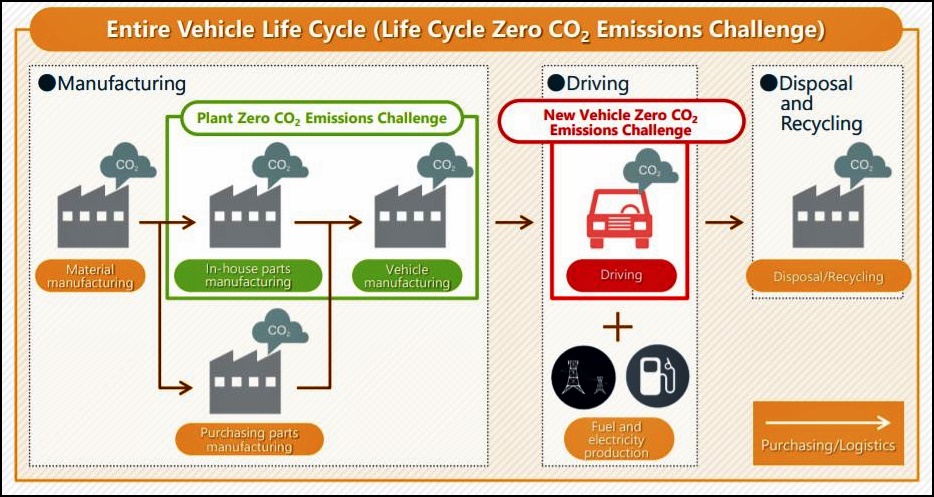

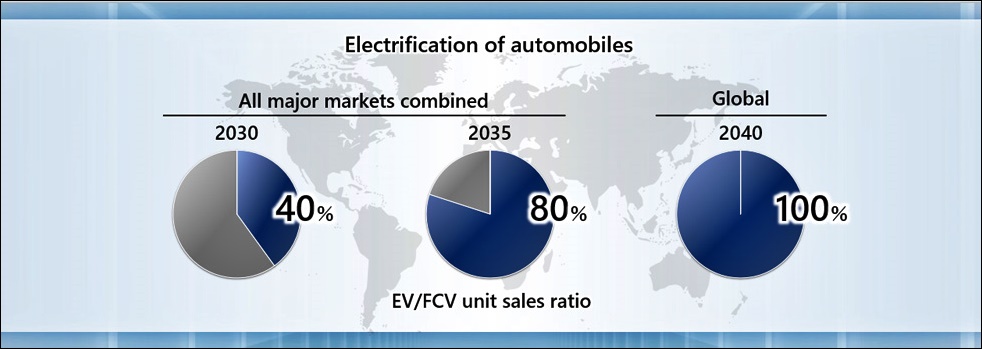

Transitioning to electric vehicles is one approach Toyota is taking to help create a carbon-neutral society. To achieve this goal, it is developing multiple electrified technologies, including hydrogen, which it views as one of the key building blocks for CO2 reduction.

Second generation fuel cell modules

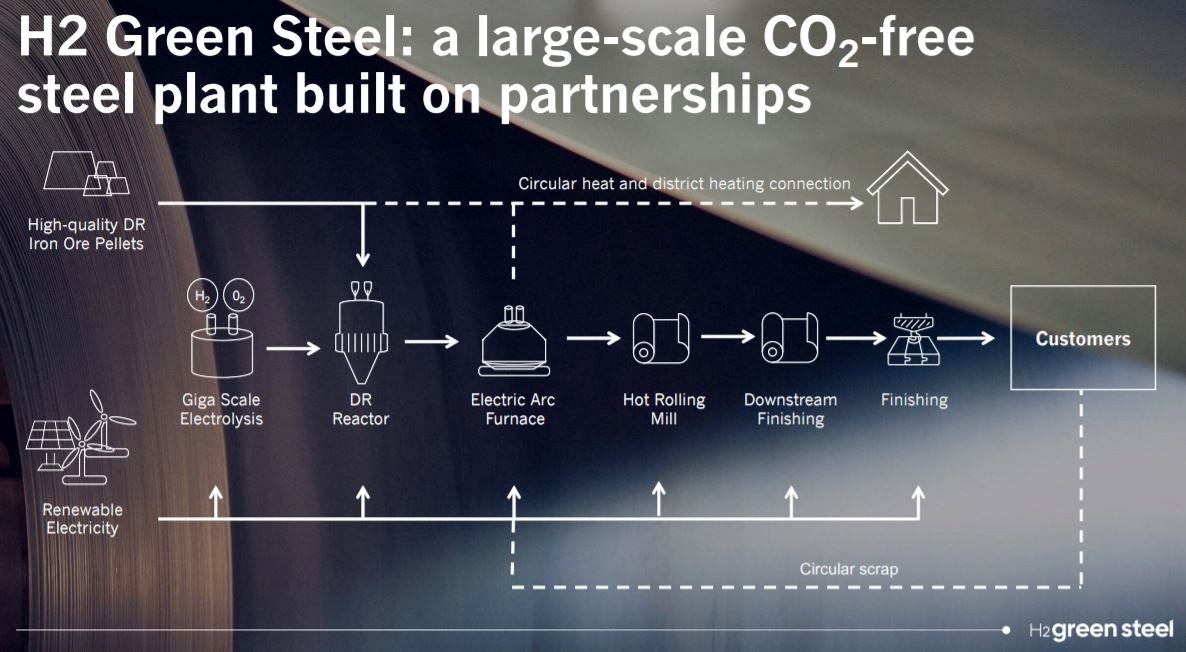

To help expand its hydrogen technology from cars to more diverse applications, it has repackaged the advanced fuel cell system used in its Mirai saloon into compact fuel cell modules. From January 2022, Toyota will start production of these second generation modules.

The new system has been packaged into modules that are more compact, lighter in weight and provide greater power density. They are available in two formats: a cube and a flat, rectangular shape, allowing greater flexibility and adaptation for different applications.

Toyota began fuel cell development in 1992 and has since continued to refine its hydrogen technology. The second generation fuel cell modules will be assembled by a manufacturing team at Toyota Motor Europe’s (TME) R&D centre in Belgium. The new facility houses a pilot assembly line combining advanced technology content with high-quality assembly techniques.

Toyota chose Europe as the location for its second generation fuel cell module assembly as it sees demand growing significantly across the region. Working with businesses interested in using Toyota’s technology in their applications, TME’s Fuel Cell Business Unit will offer the necessary engineering support for integration. Proximity to its partners and the ability to closely monitor emerging business opportunities will allow the company to scale up supply quickly.

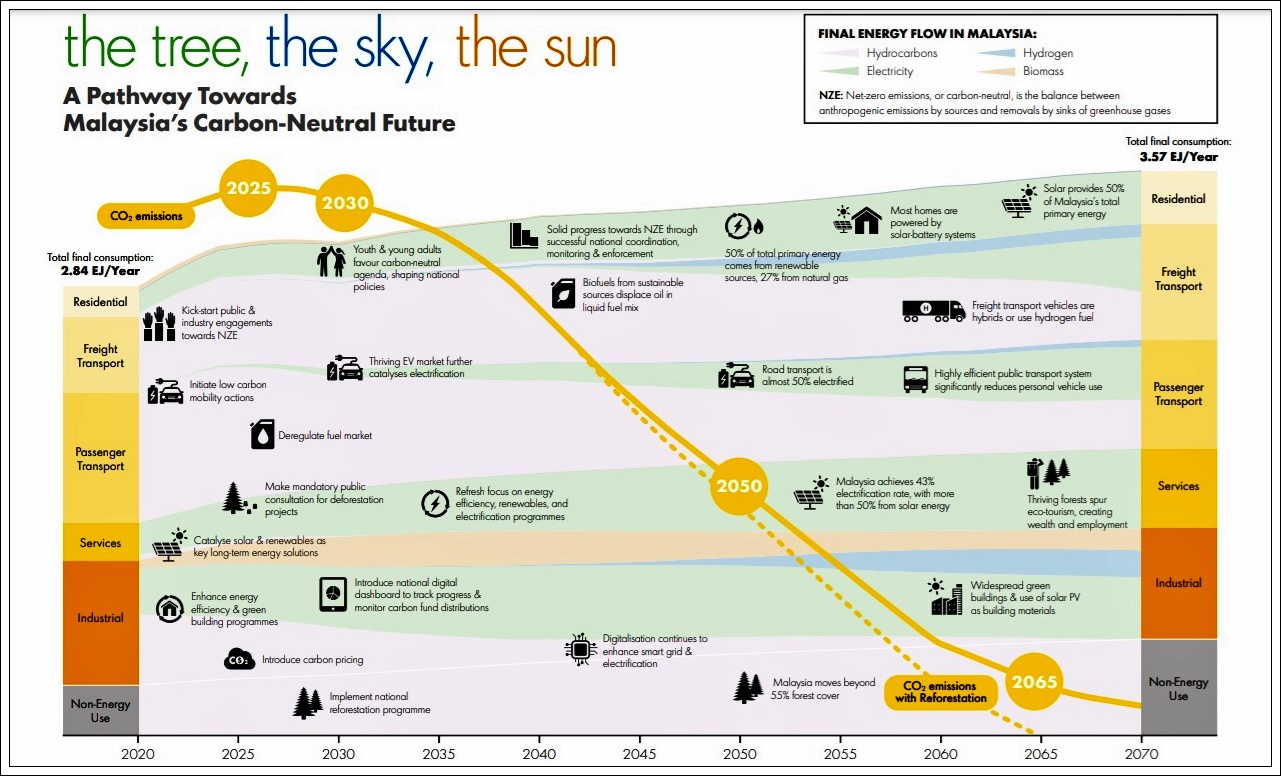

Hydrogen clusters

The expansion of a European hydrogen economy will be a key element in achieving the Green Deal’s objective of net-zero global warming emissions by 2050. The European Union has stated that, to meet this challenge, industry will need ‘climate and resource frontrunners’ to develop the first commercial applications of breakthrough technologies in key industrial sectors by 2030. The emergence of hydrogen clusters in Europe sees different sectors uniting and bringing their skills, technologies and applications together, such as truck, bus and taxi fleets and H2 infrastructure, to create viable business opportunities. This will allow them to flourish and become the nucleus of larger-scale activities.

Toyota to use motorsports to develop hydrogen-fueled engine (w/VIDEO)