Peugeot, which won the Le Mans 24 Hours in 1992 and 1993 as well as in 2009, will return next year to the World Endurance Championship (WEC) with its new-generation hypercar, the 9X8. Now under development, the 9X8 showcases Peugeot’s Neo-Performance strategy which combines technology and sportiness in both the carmaker’s road and racing cars.

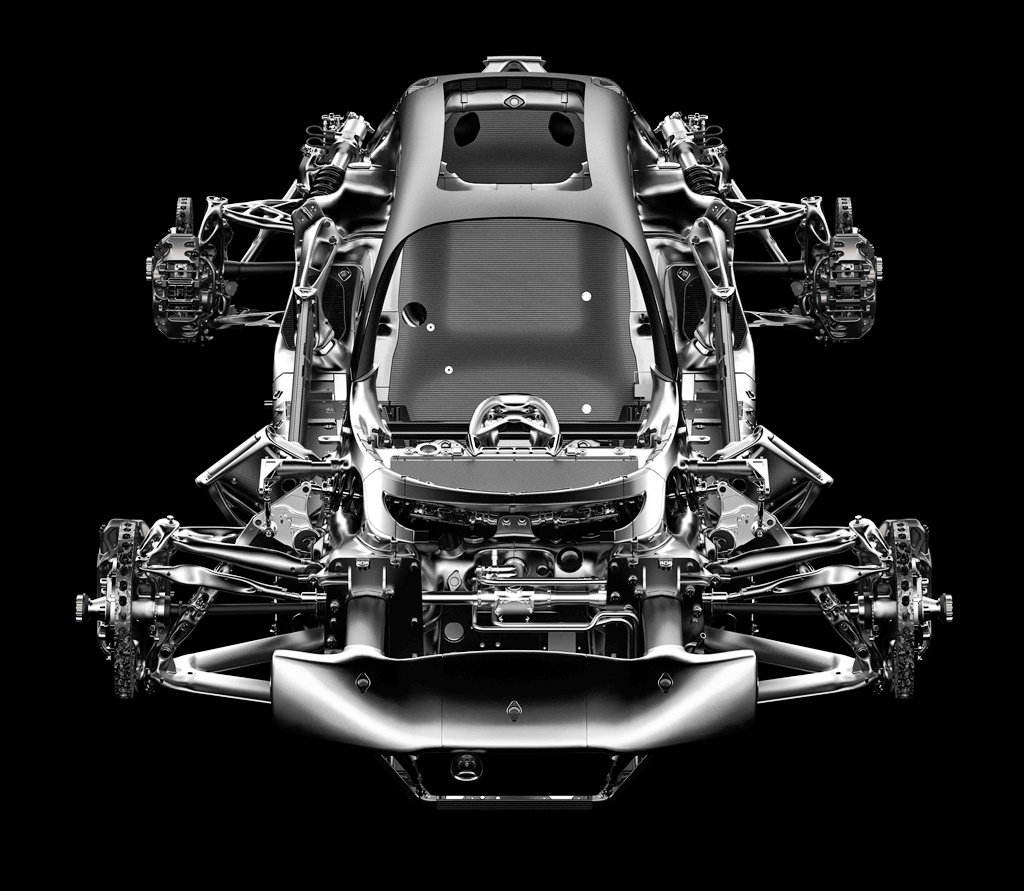

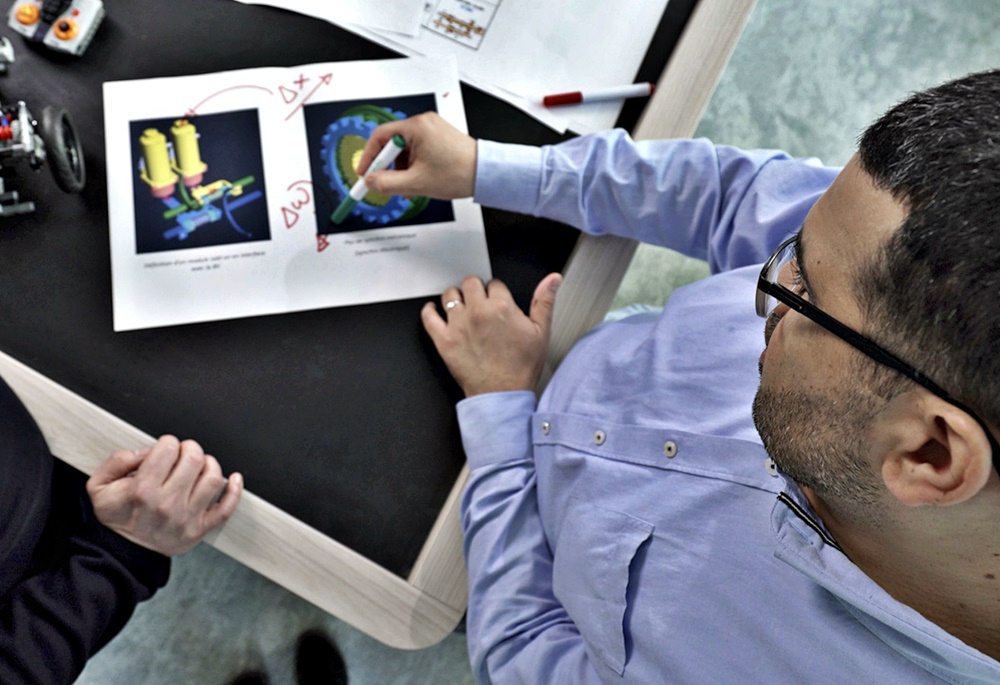

A project between Peugeot Sport and Peugeot Design, the 9X8 is a direct successor of the Peugeot 905. The designers worked closely with engineers to explore new aerodynamic solutions and styling ideas. Greater flexibility, allowed by the WEC’s new technical rules regarding aerodynamics, permits new thinking that favours the emergence of innovative cars, allowing for new creative processes and a break away from established procedures to produce a hypercar for a completely new era.

What ‘9X8’ means

‘9X8’, the designation, is derived from a combination of the brand’s motorsport heritage and vision for the future. The ‘9’ continues the series used by Peugeot on its previous endurance racing cars. The ‘X’ refers to the all-wheel drive technology and hybrid powertrain. The ‘8’ is common across all of Peugeot’s current models – from the 208 and 2008 to the 308, 3008, 508 and 5008.

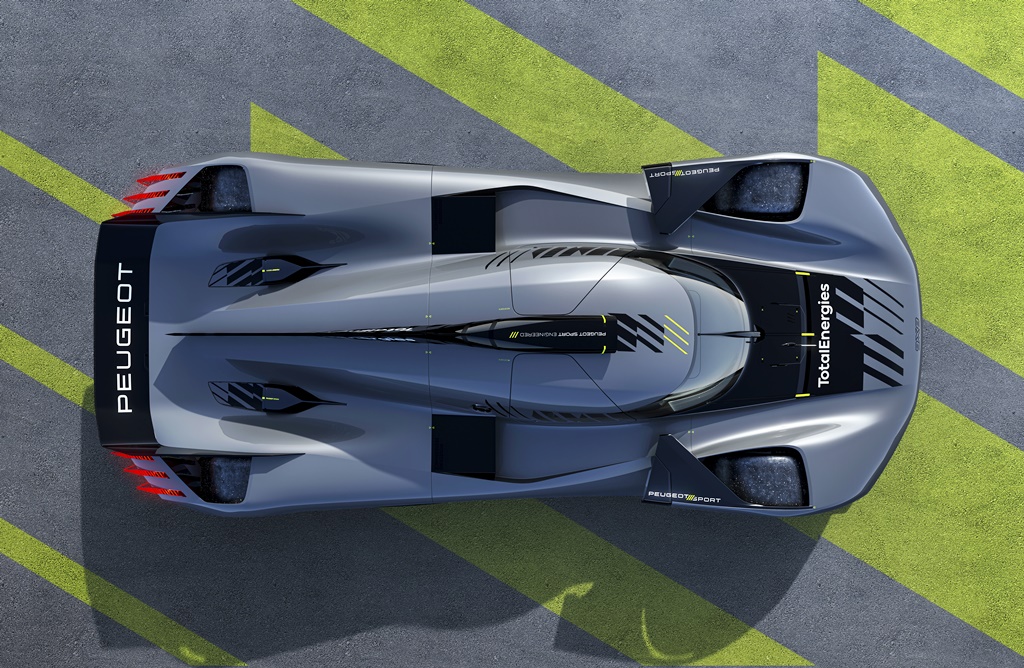

The 9X8’s front and rear lighting signatures, which take the form of three claw-like strokes, are familiar Peugeot trademarks, while the brand’s new lion’s head logo features at the front and on the sides of the car. “Since the 9X8 is a Peugeot, the original sketch that steered our work portrayed a big cat ready to pounce, a stance which we have suggested by the slightly forward-tilting cockpit. The overall lines of the Peugeot 9X8 express the brand’s styling cues, while its sleek, racy, elegant forms inspire emotion and dynamism,” explained Peugeot’s Design Director, Matthias Hossann.

No rear wing necessary

The finely-chiselled details of the rear-end design includes the quip ‘We didn’t want a rear wing’ above a wide diffuser. Rear wings were first seen at the Le Mans 24 Hours on the Chaparral 2F which contested the race in 1967, meaning this is the first time their use has been questioned in more than half a century. The 9X8’s innovative rear stems from research carried out by Peugeot Sport’s engineering team as they worked to ensure the model was as aerodynamic as possible, whilst maintaining an eye-catching style.

“The absence of a rear wing on the Peugeot 9X8 is a major innovative step. We have achieved a degree of aerodynamic efficiency that allows us to do away with this feature. Don’t ask how, though! We have every intention of keeping that a secret as long as we possibly can!” said Jean-Marc Finot, Motorsport Director of Stellantis (Peugeot is part of the Stellantis Group).

Distinctive cockpit colour scheme

“Inside, we wanted to take a special approach to the cockpit which, until now, has tended to be a purely functional and indistinctive aspect of racing cars, with no brand identity whatsoever. The combination of our colour scheme and Peugeot’s i-Cockpit interior styling signature have provided the 9X8’s cockpit with a distinctive feel and make it immediately identifiable as a Peugeot.”

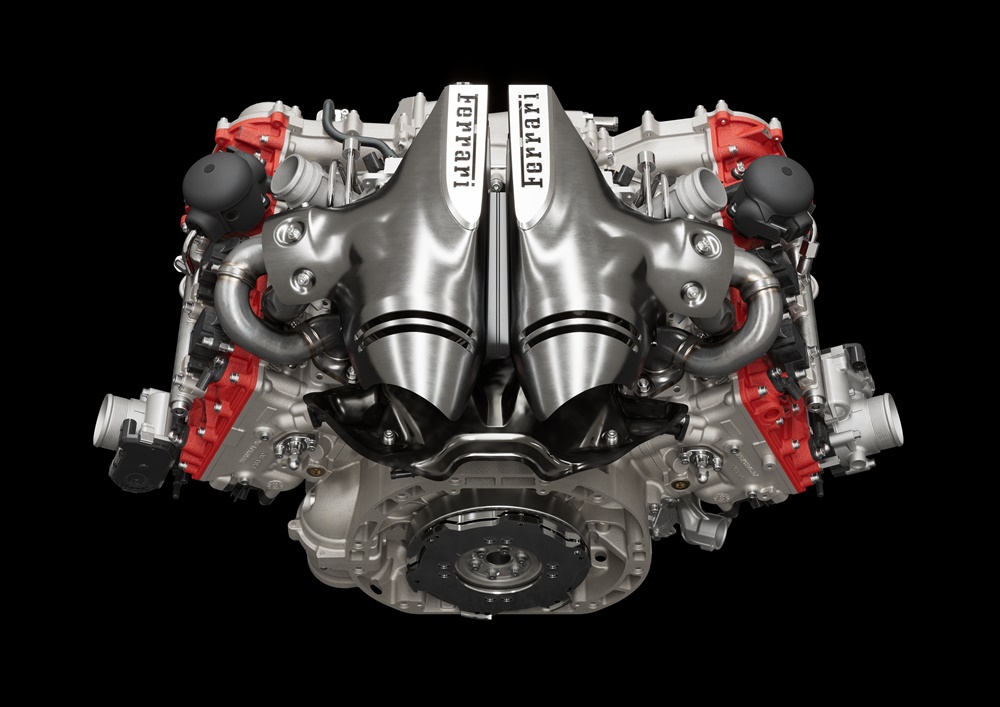

Peugeot HYBRID4 powertrain

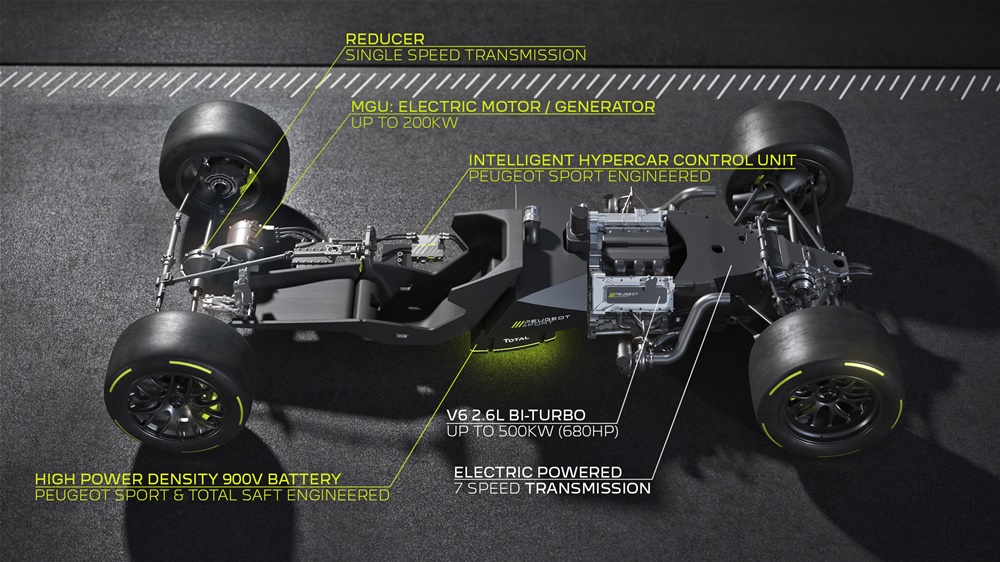

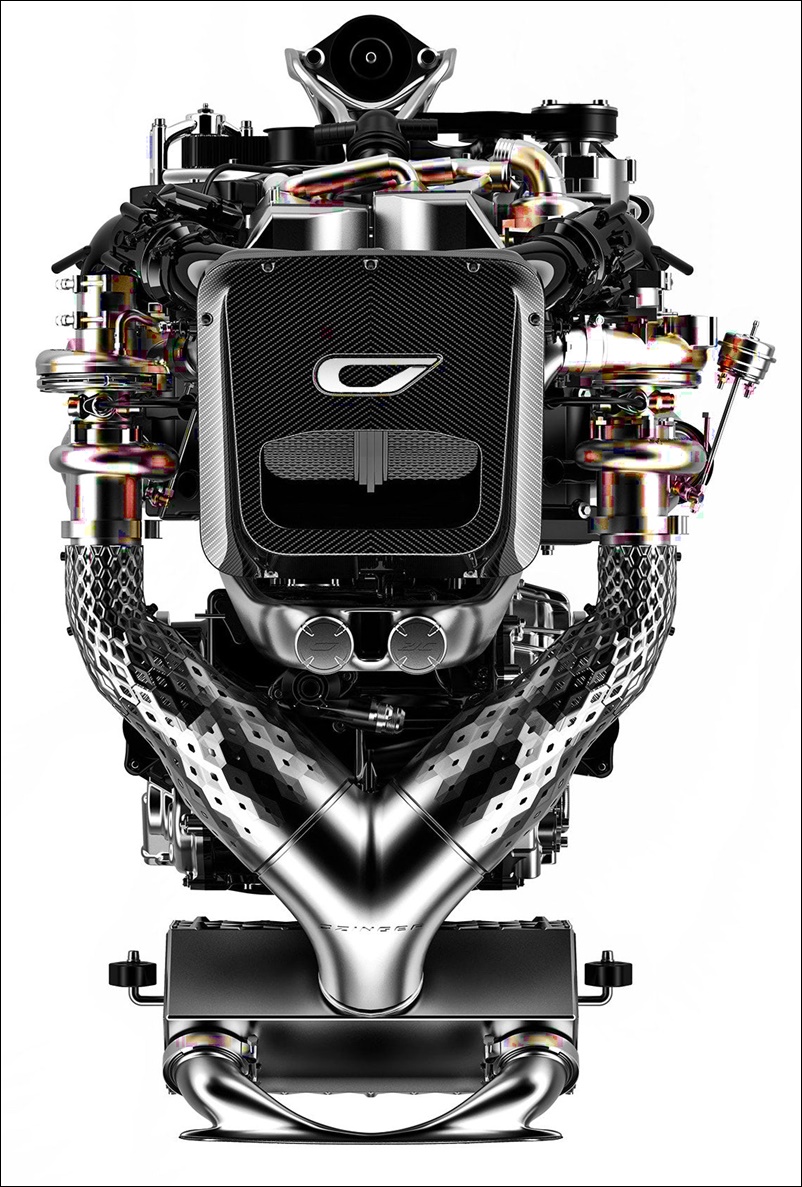

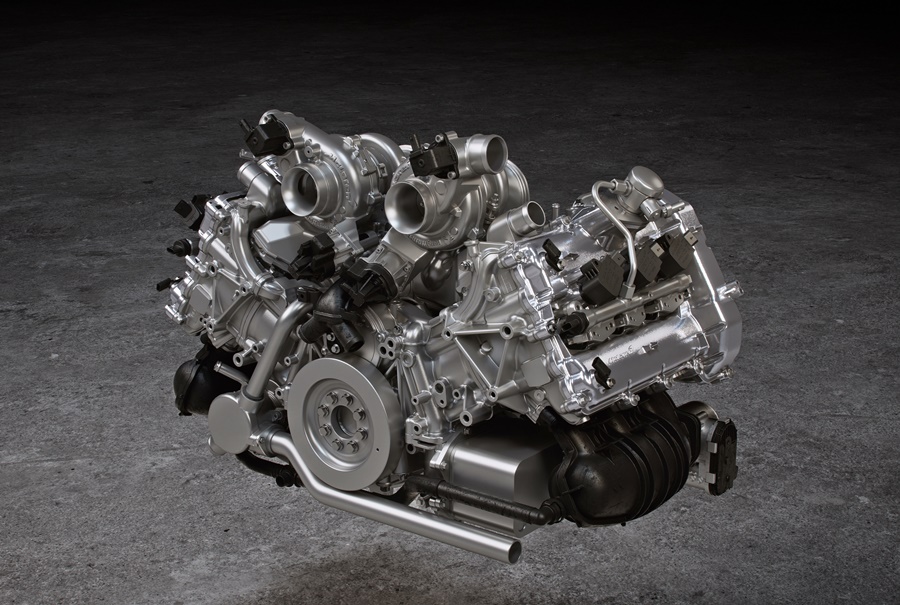

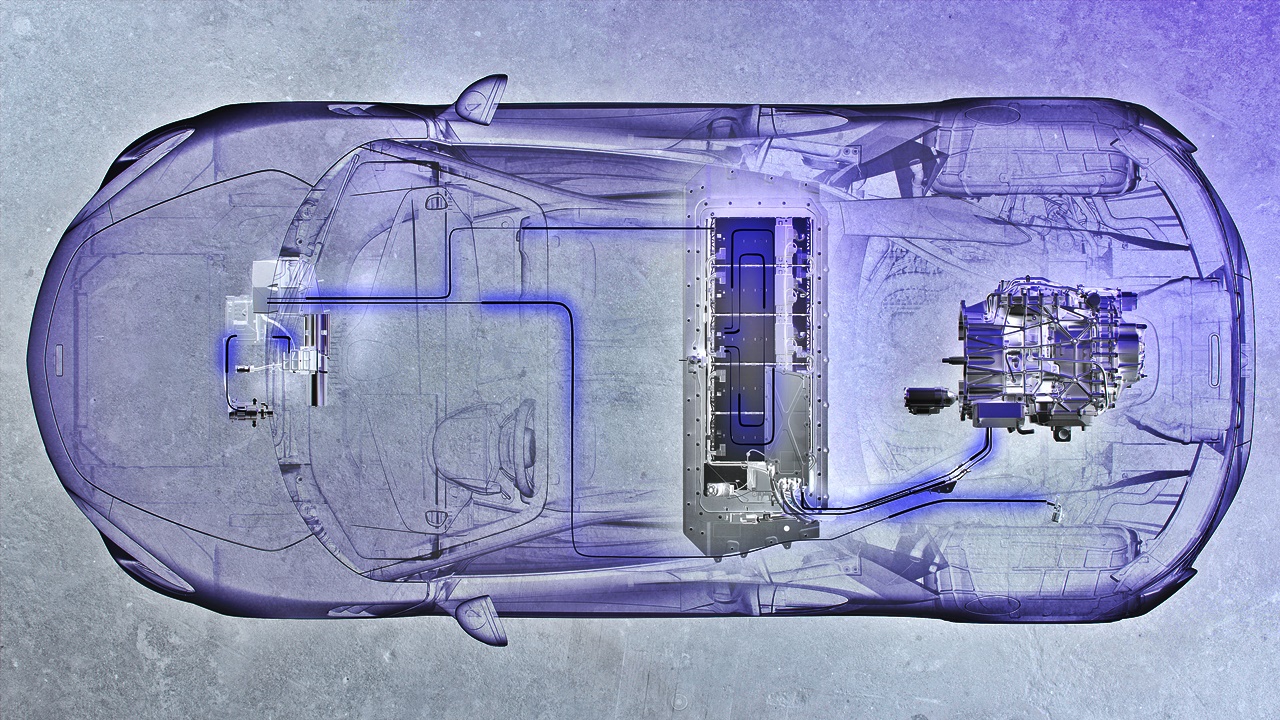

The 5-metre long racing car has a rear-mounted, 2.6-litre, bi-turbo, 680-bhp 90-degree V6 as part of the Peugeot HYBRID4 powertrain. The system output gets another 200 kW from the front-mounted 200kW motor-generator unit powered by a high-voltage 900V high-density battery pack.

The battery pack is located in a carbonfibre casing inside the car’s monocoque structure, behind the driver and underneath the fuel tank. It has been designed to combine durability with consistent performance during races of durations of up to 24 hours, and even beyond.

Although the system output is over 500 kW, the regulations set a maximum power output of just 500 kW during races. The regulations also forbid the use of electrical energy below 120 km/h, so the motor generator unit only engages once this speed has been reached. The car must pull away from standstill under the power of its internal combustion engine alone.

At full power, the power output is limited to 300 kW and adjusted as a function of the power delivered by the motor generator unit at 200 kW which is directly dependent on the battery level. When the motor generator unit comes into use, the car automatically switches to 4-wheel drive, thereby modifying its drivability.

When the battery pack is empty, the engine reverts to 500 kW power output and the drivetrain reverts to rear-wheel drive. During races, the battery will be fully charged prior to the start by means of a mains-connected plug-in hybrid charger. Once on the track, the battery will function completely independently and be charged only by the kinetic braking energy recovery system.

‘An extreme laboratory’

Peugeot’s CEO, Linda Jackson, says there’s more to the company’s involvement in endurance racing than the sporting aspect. “Endurance racing is a form of motorsport that provides us with an extreme laboratory, which explains why our association with Le Mans is so strong. More significant perhaps than the results we obtain on the racetrack are the opportunities it provides to prove our technology and the fruit of our research work in a race that throws extreme conditions at you for 24 hours,” she said.

“Le Mans gives us a competitive environment to validate the hybrid systems and technologies we are currently developing to reduce the fuel consumption – and therefore CO2 emissions – of our road cars. The teams at Peugeot Sport are proud when they see their research carried over to our production models,” she added.

Ferrari to officially take part in Le Mans Hypercar class from 2023