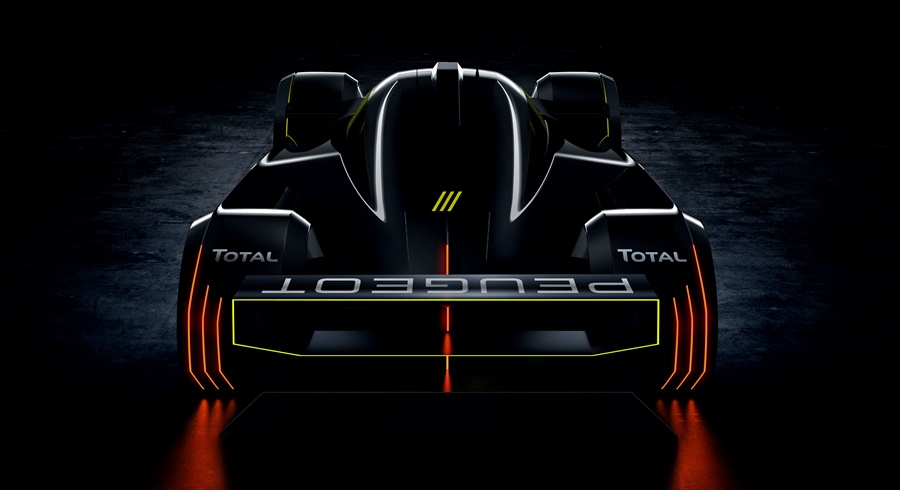

After a decade-long absence, Peugeot will return to endurance racing, including the Le Mans 24 Hours, in 2022. By then, it will have completed development of an all-new hypercar defined in the new FIA World Endurance Championship (WEC) regulations.

Development by Peugeot Sport and Total

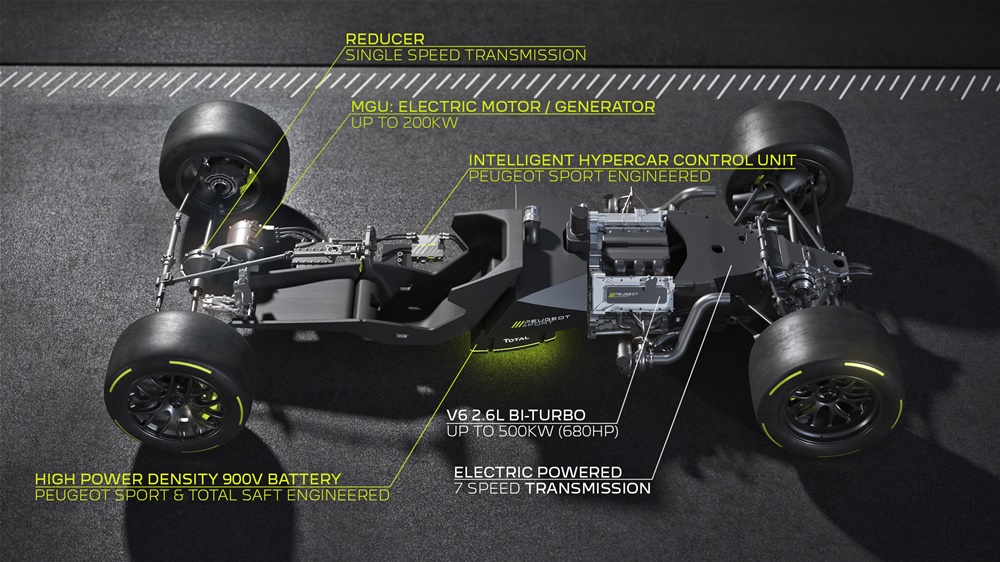

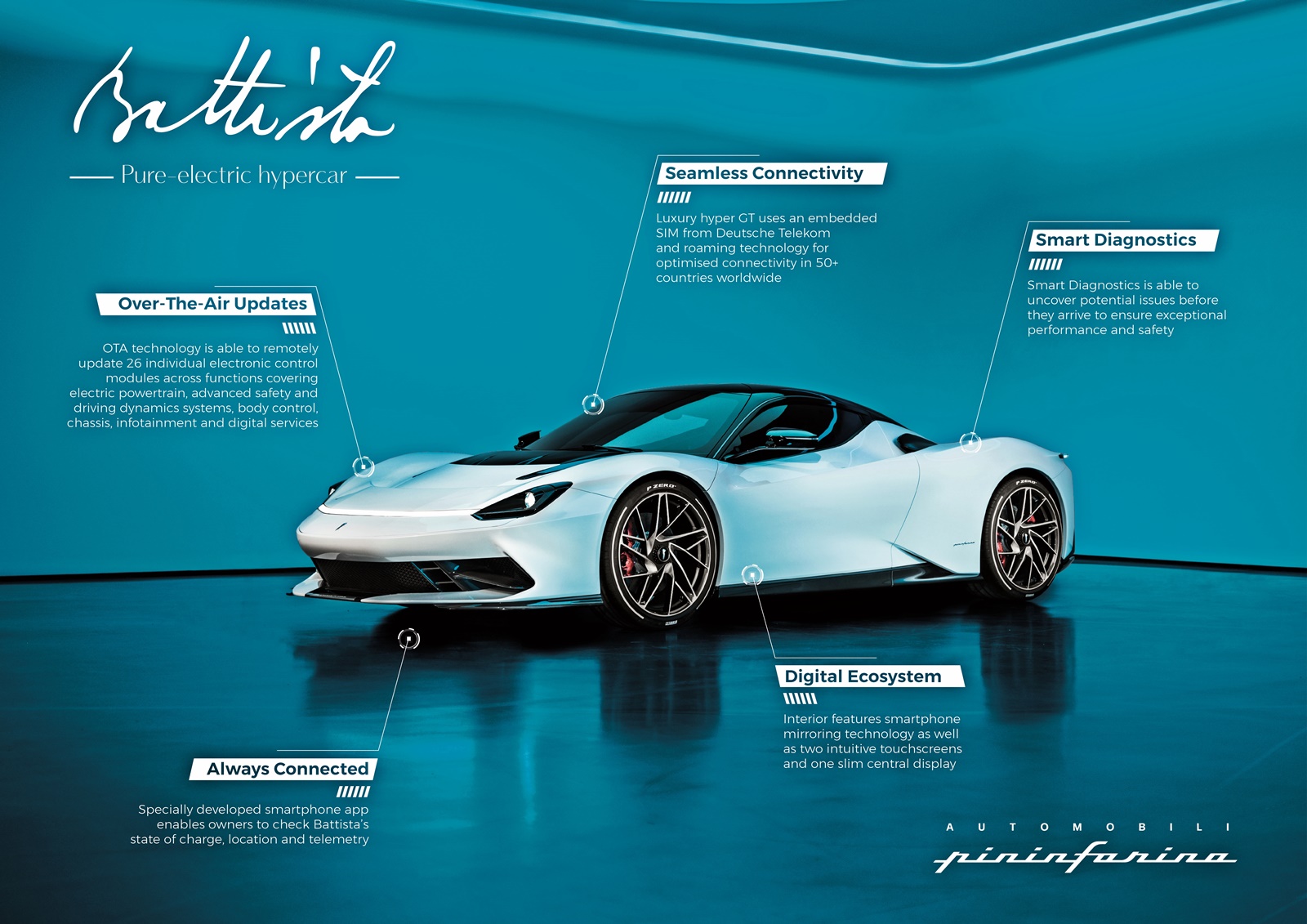

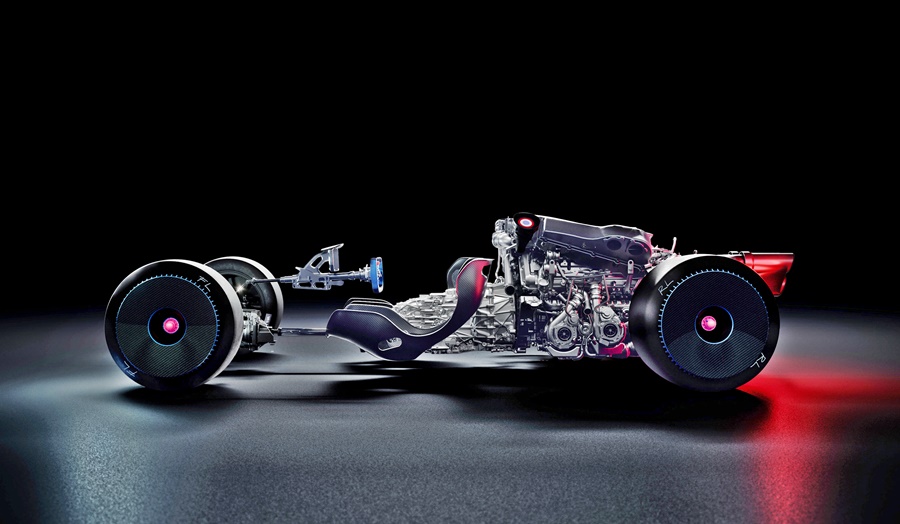

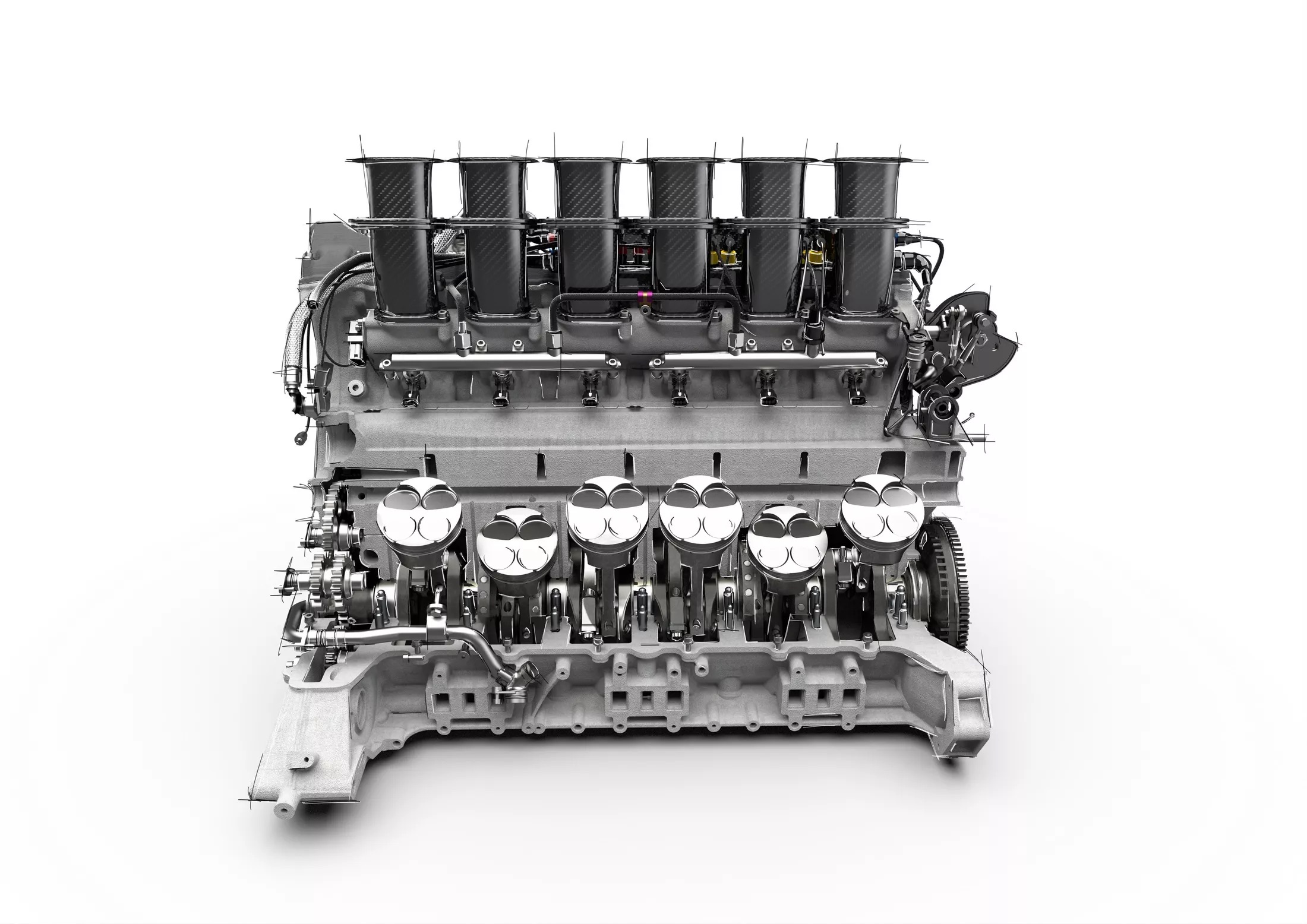

The hypercar will be known as the Peugeot Hybrid4 500KW and its powertrain is now being developed by Peugeot Sport and Total (and its subsidiary, Saft). Details of the powertrain which have been revealed show a mid-rear, 2.6-litre, 500 kW (680 bhp), twin-turbo, V6 , petrol internal combustion engine combined with a front-mounted 200 kW (272 bhp) motor generator unit, with a high-power density battery. The smart powertrain will have energy flow management, a key to high performance.

Although the 165-kg engine can deliver 500 kW and the motor generator unit has a capacity of 200 kW, the regulations set a maximum power output of just 500 kW during races. The regulations also forbid the use of electrical energy below 120 km/h, so the motor generator unit only engages once this speed has been reached. The car must pull away from standstill under the power of its internal combustion engine alone.

At full power, the power output is limited to 300 kW and adjusted as a function of the power delivered by the motor generator unit at 200 kW which is directly dependent on the battery level. When the motor generator unit comes into use, the car automatically switches to 4-wheel drive, thereby modifying its drivability – through high-speed corners, for example,

When the battery pack is empty, the engine reverts to 500 kW power output and the transmission returns to rear-wheel drive. During races, the battery will be fully charged prior to the start by means of a mains-connected plug-in hybrid charger. Once on the track, the battery will function completely independently and be charged only by the kinetic braking energy recovery system.

The robotised sequential 7-speed (plus reverse) gearbox will be controlled by steering wheel-mounted paddle shifters, and the Peugeot Sport-developed brake-by-wire system will also be managed electronically.

The driver will be able to adjust the level of engine-braking generated by the electric motor under deceleration and the force applied by the pads to the braking discs to achieve the optimum electric regenerative/hydraulic braking split. Optimal energy management, both under acceleration and during energy recovery, will consequently be key to the car’s performance and efficiency.

The architecture of the Peugeot HYBRID4 500KW powertrain is the result of a highly- detailed brief shaped by the new FIA WEC regulations,” noted François Coudrain, Peugeot Sport’s WEC Programme Powertrain Director. “We initially considered a single turbo, but that would have prevented us from achieving our engine’s centre of gravity target. A twin-turbo V6 block offers the best trade-off between technology, weight, packaging of the engine’s ancillaries, reliability and performance.”

Innovative battery concept

The high-density, high-power battery pack has been developed jointly by Peugeot Sport and Saft, a Total subsidiary. As one of the keys to high performance, it will need to be integrated perfectly, physically inside the car and in the powertrain’s energy-management process. Working from a specification written by Peugeot Sport, Saft’s engineers selected the best type of cells for the battery which favours power over energy density, consistent with the needs of endurance racing.

“The main parameter will be to optimise how the energy stored in the battery is used,” explained Kamen Nechev, Saft’s Chief Technical Officer. “To achieve this, you need an extremely short charge-time combined with high-capacity storage cells to form a package that enables maximum power to be delivered as rapidly as possible. The most competitive solution resides in the management of charge optimisation and the amount of power available in real time.”

The new battery will be located in a carbonfibre casing inside the car’s monocoque structure, behind the driver and underneath the fuel tank. It has been designed to combine durability with consistent performance during races of durations of up to 24 hours, and even beyond.

Click here for other news and articles about Peugeot.