America has many races of its own and understandably, the American carmakers have focussed more on their domestic events. In as far as the legendary events in Europe are concerned, American cars have not featured strongly though many have been entered.

However, where the classic Le Mans endurance race is concerned, Ford has participated in the past and also present and the Ford GT is America’s only Le Mans-winning car. That was back in 1966 and Ford won another three years in a row.

Ford Performance recalls this achievement in endurance racing with two new enhancements today for the 2021 Ford GT. One is the first ever Heritage Edition inspired by the original model’s first endurance win at the 1966 Daytona 24 Hour Continental race, plus an all-new Studio Collection package offers even more exclusivity and design enhancements.

“For this Heritage Edition, the Ford Performance team went deeper into the Ford GT’s race history and crafted a limited-edition model that stylistically honours the 55th anniversary of the Daytona 24 Hour endurance race that would eventually lead to our successes at Le Mans,” said Mike Severson, Ford GT program manager. “Plus, for customers who want to highlight the carbonfibre body and functional cooling ducts that help deliver Le Mans-winning performance, the Ford GT Studio Collection offers another new way GT fans can personalize their supercars.”

The Daytona-inspired Heritage Edition

The latest Heritage Edition to join the Ford GT supercar family is a tribute to the winner of the 1966 Daytona 24-Hour Continental, where Ford achieved its first 24-hour endurance win, which is captured in the 2019 film ‘Ford v Ferrari’ – or ‘Le Mans ’66’, as it is known in Europe.

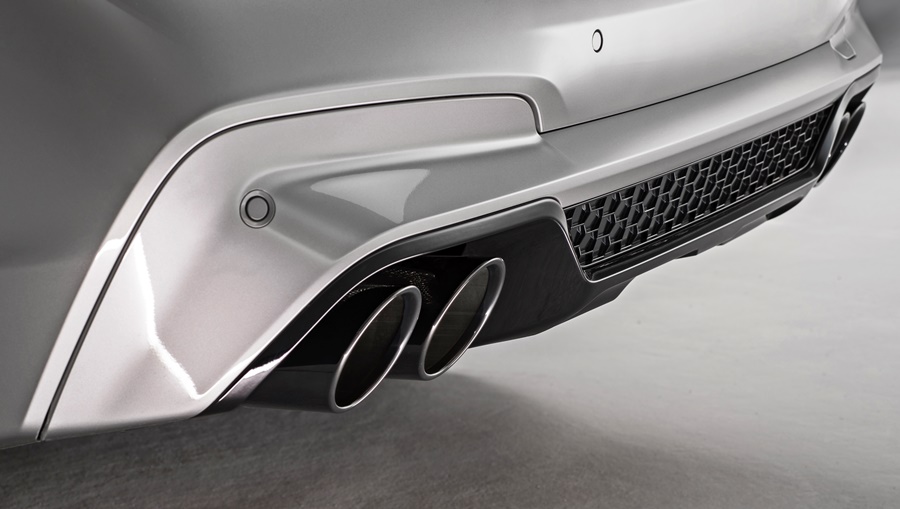

Inspired by the bold white, black and red exterior of the 1966 GT40 MK II racing car, the Heritage Edition features Frozen White exterior paint with exposed carbonfibre bonnet adding stark contrast. Asymmetrical Race Red accents on the front fascia and roof edge, driver’s side door and underneath the rear wing add distinct visuals, while exposed carbonfibre shapes the signature 98 roundel graphics and highlight the lightweight body.

Unique Ford graphics on the lower rear-quarter panels plus one-piece Heritage Gold 20-inch forged-aluminium wheels paired with red lacquered Brembo monoblock brake calipers complete this new exterior livery.

Inside, the lightweight driver-centric interior features unique appointments including black Alcantara suede wrapping the instrument panel, headliner and steering wheel rim, while anodized red paddle shifters and red Alcantara suede performance seats add dramatic contrast to the interior.

For customers wanting an even bolder look, an optional Heritage Upgrade Package includes 20-inch exposed carbonfibre wheels with a unique gloss red-painted inner accent barrel, while monoblock brake calipers are lacquered in black and detailed with Brembo lettering in red. Inside, ghosted 98 roundels provide a subtle contrast on both driver and passenger carbonfibre door panels of this this package.

Ford GT Studio Collection

Ford Performance has also created an exclusive series for the supercar line-up known as the Ford GT Studio Collection. This all-new graphics package with customizable colours highlights key styling elements, including the functional cooling ducts that helps the 2021 Ford GT deliver all 660 horsepower during the most strenuous, high-temperature sessions at the track.

The body and graphics can be customized with seven standard colours or further personalized with an extended palette offering endless colour combinations for even greater exclusivity. Only 40 cars are slated to receive the Studio Collection package across the 2021 and 2022 model years.

Ford originally planned to make just 500 units over two years from 2016. But demand was so great (some 6,500 people wanted to buy one when it was announced) that another two years of production were added, raising total output to 1,000 units. Then in 2018, the company again extended the production period that was to have ended in 2020 to 2022, and added another 350 units.

So for now, production is to end in 2022 with a total of 1,350 units delivered. But with a new President, Jim Farley, coming on board and one who is a car guy – and even goes racing himself – things may change. We might even see more sports-focussed models in coming years…

Visit Sime Darby Auto ConneXion to know more about Ford models available in Malaysia, including the Mustang which comes with full aftersales support.