Most of today’s motor vehicles are powered by engines which run on fossil fuels – petrol, diesel, natural gas – and apart from causing pollution from the exhaust gases that are by-products of combustion, there is also the problem of diminishing fuel supplies. The fuels come from deep underground and were formed millions of years ago from dead plants, dinosaurs and other living creatures. So there is a specific quantity of these fuels underground and while there are varying predictions on how long they will last, the fact is they will eventually be finished.

The auto industry has understood this for a long time and has searched for alternative fuels to use, preferably those which can be renewable. At this time, some approaches using electricity and hydrogen are already in use in hybrid and fuel cell vehicles and while they are not necessarily the answers, they are helping to slow down the rate of consumption of fossil fuels so that new technologies can be developed that do not need such fuels.

Sunshine has energy too and technologies have already been developed to collect sunshine and convert to electricity which can be used for various purposes, like water heaters in the home or powering machinery at factories. It used to also be a dream to be able to use solar energy to power cars but the technology has been slow to advance, and it takes a huge amount of conversion to generate enough electricity for such a purpose as propulsion.

Nevertheless, the technology has reached a stage today where it is possible to at least use sunshine for cars though not necessarily directly powering the electric motors. The electricity that is converted from sunshine can go into a storage battery which then provides electricity for the motors to run. There are a number of manufacturers which have already developed prototypes and some are on the verge of commercializing them for sale to the public.

Sono Motors, based in Germany, is one of the companies with a solar energy vehicle (SEV) almost ready to be delivered to customers. In fact, its SEV known as Sion has entered the validation stage this month with over 30 units to undergo real-world testing in Europe and the USA. The company plans to start producing 43,000 cars a year and the total production volume is expected to be 257,000 units over a 7-year period. The former SAAB factory in Sweden will be used as the production facility.

The Sion has been a dream of the Sono Motors founders for at least 10 years, but they only started crowdfunding to implement a project in 2016 and 2017 where they collected over 2 million euros (about RM9.25 million). By January 2021, they presented their first prototype of the Sion with the design that will be used for the production model.

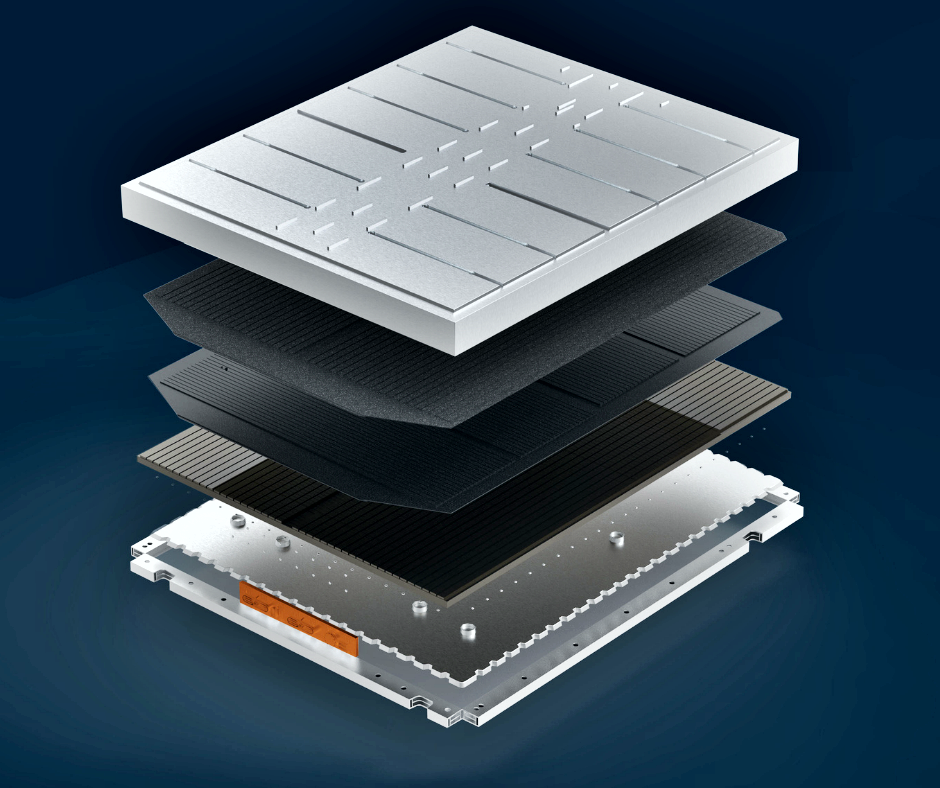

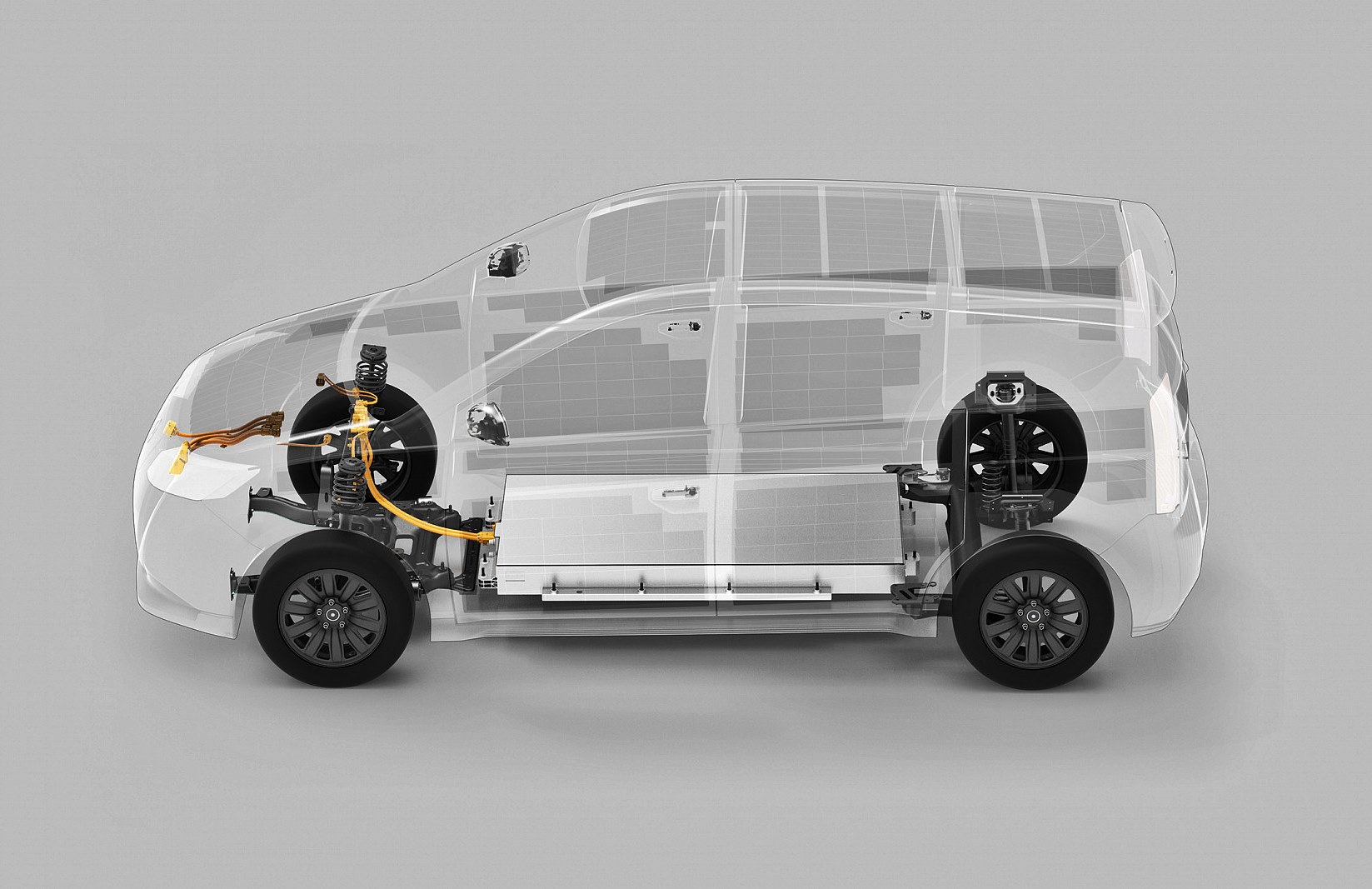

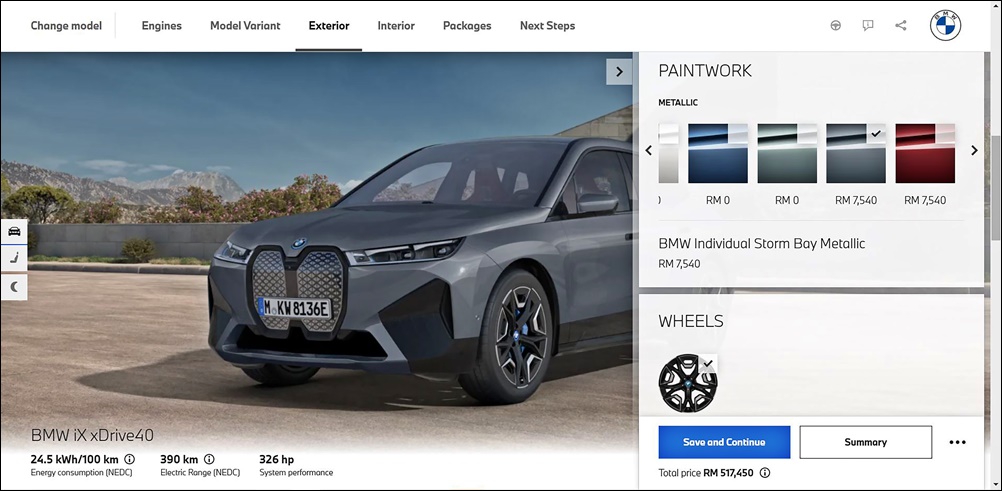

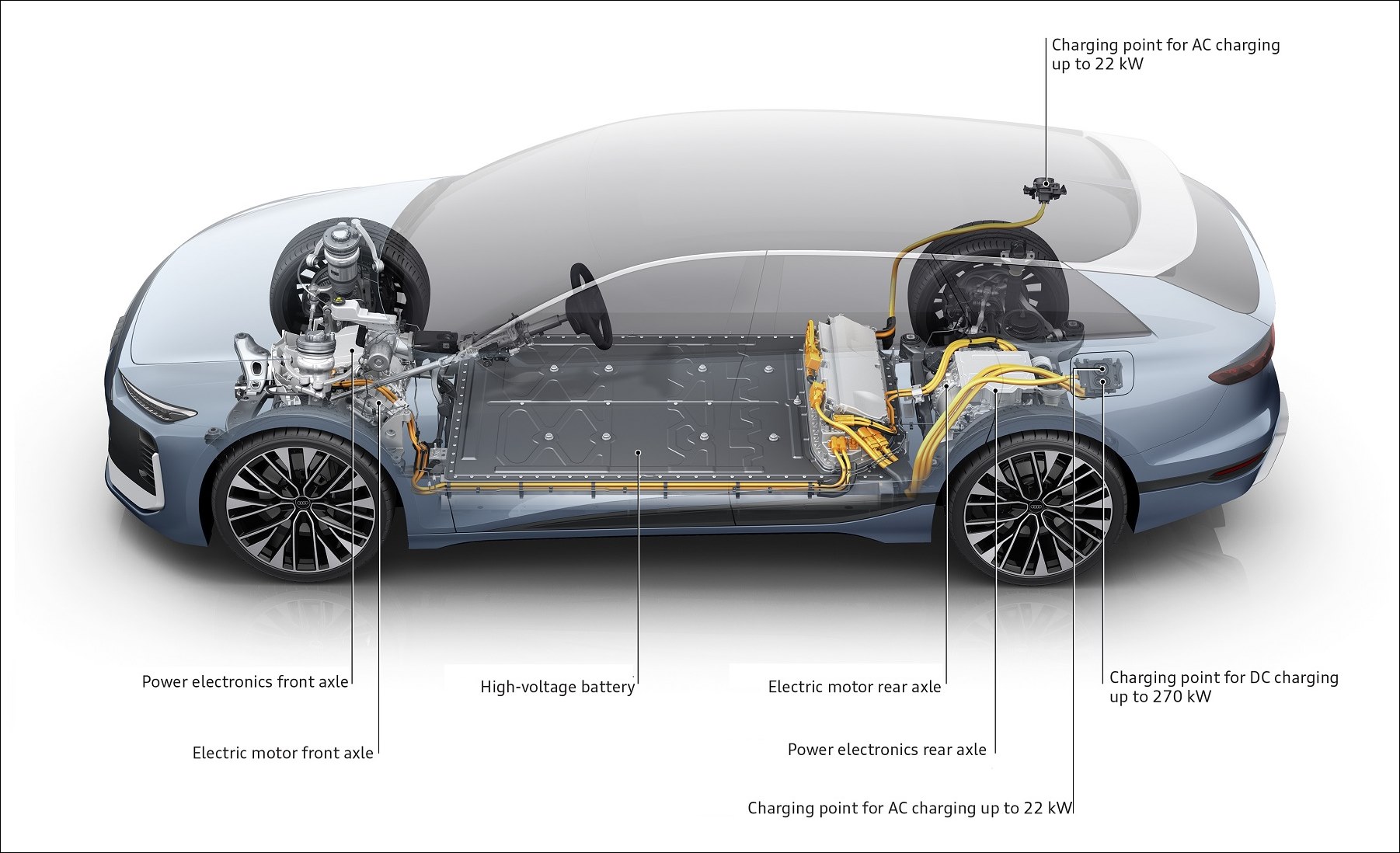

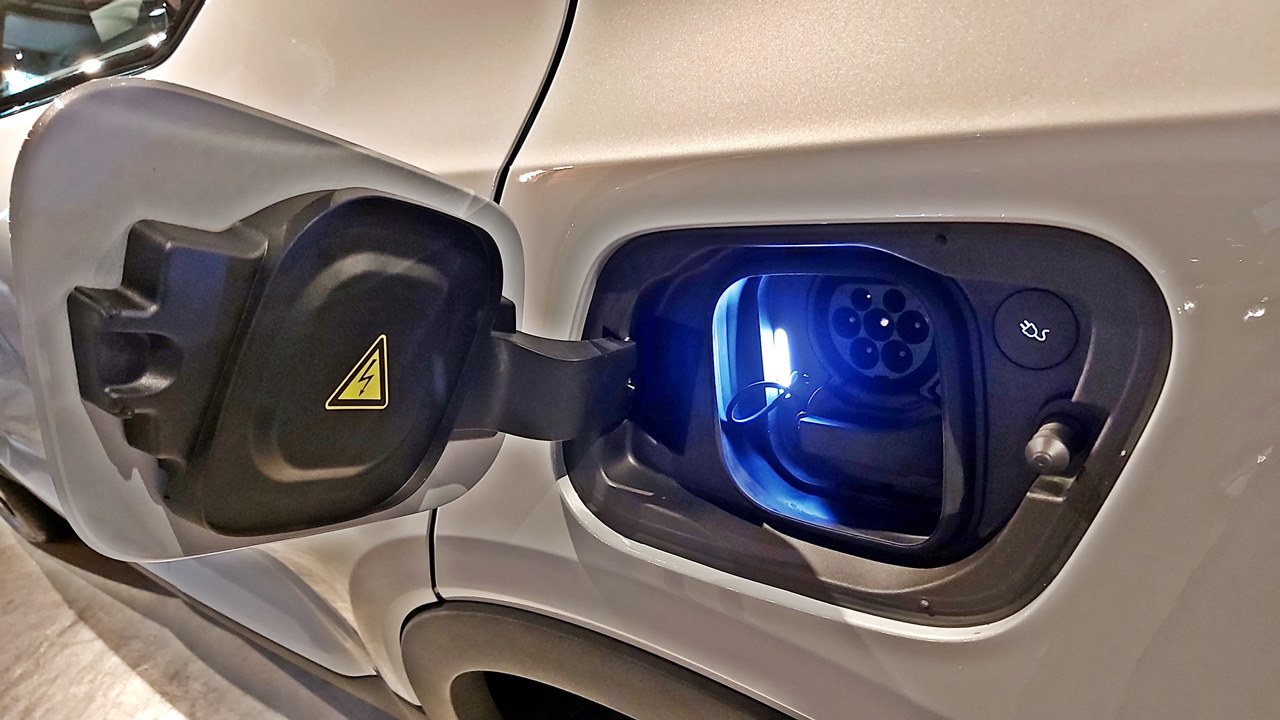

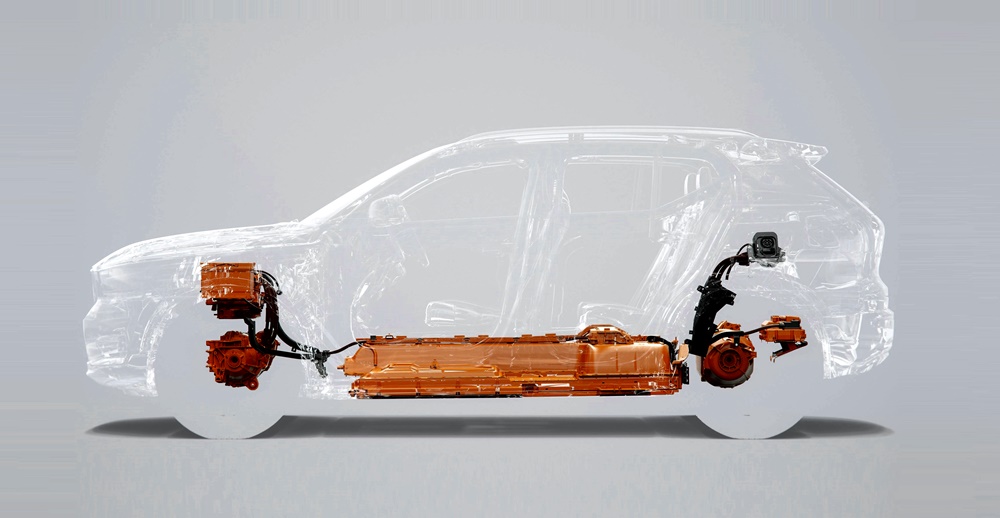

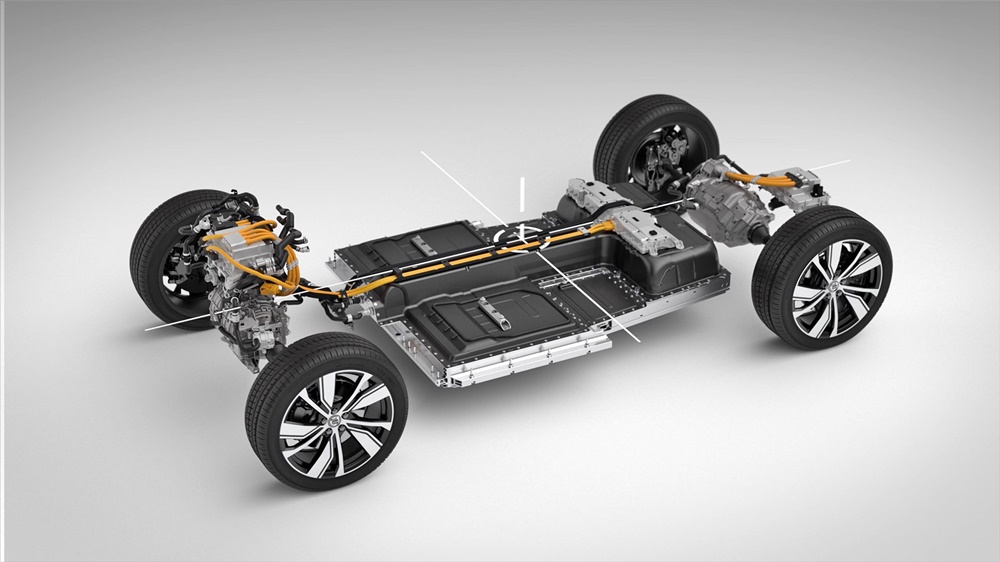

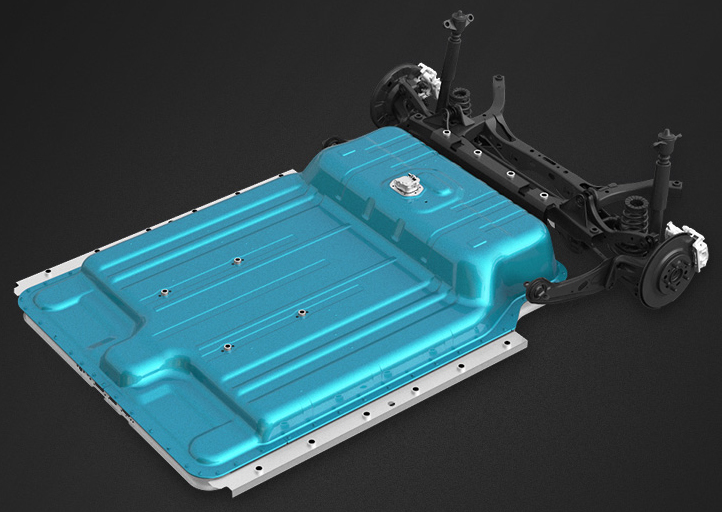

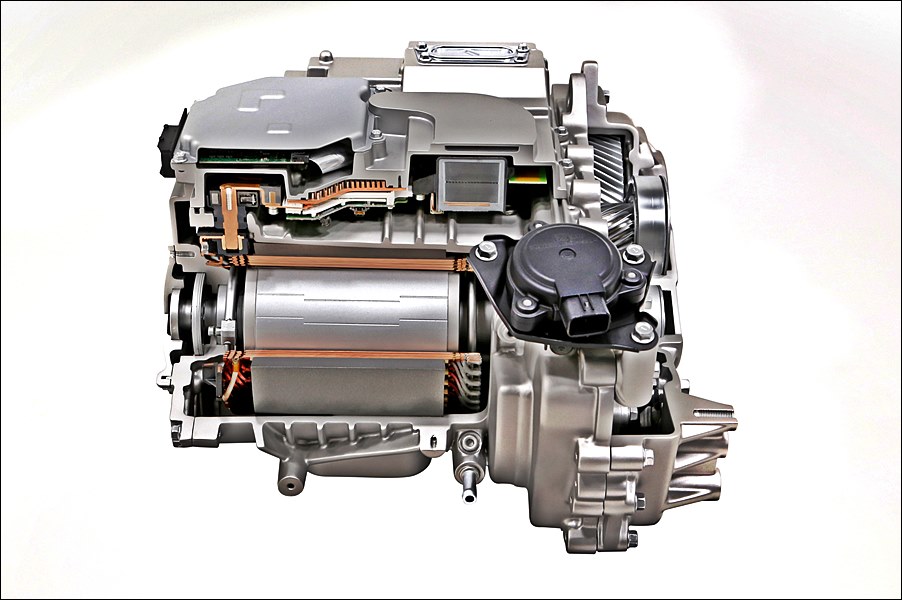

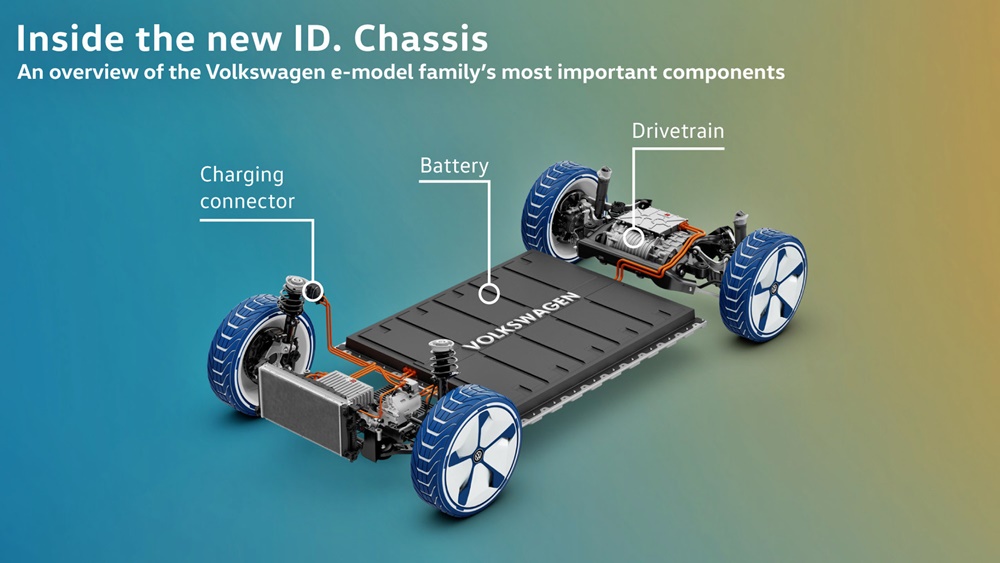

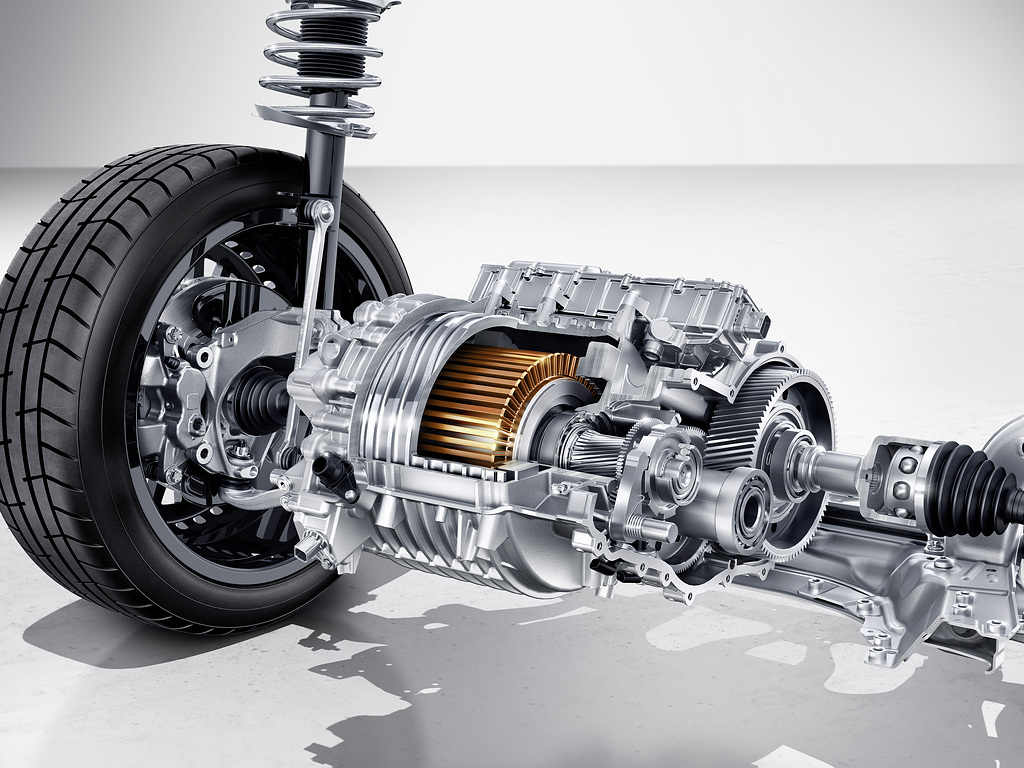

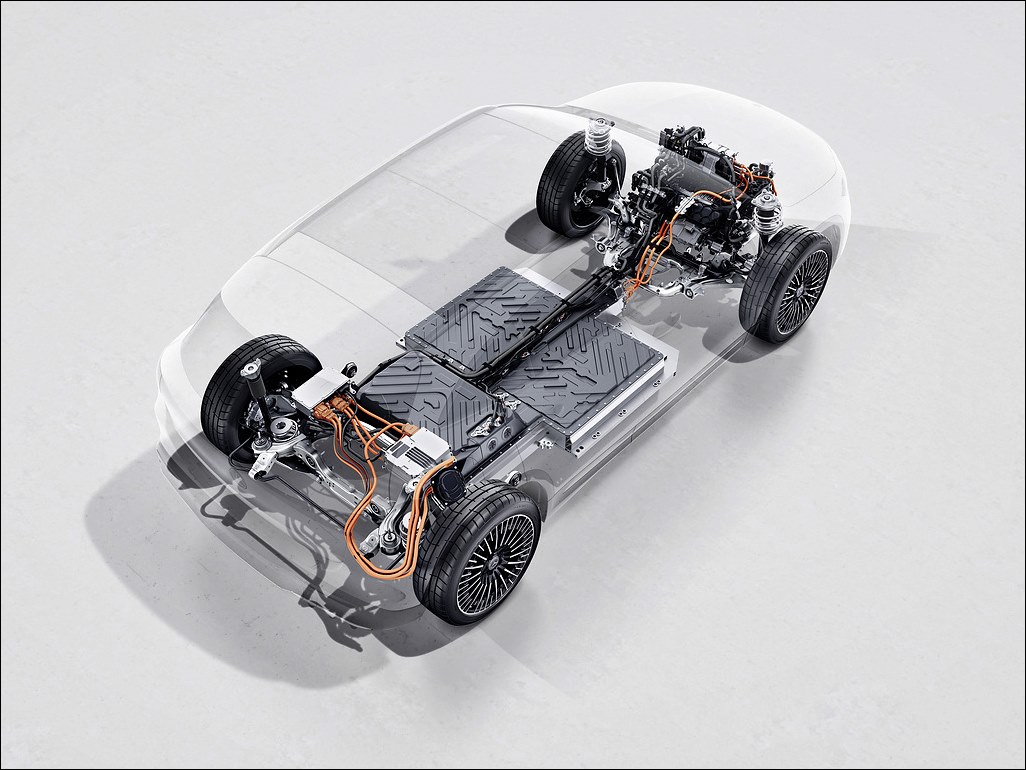

While the design is fairly conventional, key to the technical aspect (as with any electric vehicle) is the battery pack to power the 120 kW electric motor. Sono Motors has opted for a more powerful 54 kWh battery for the Sion which is a lithium iron phosphate type (pictured above) considered to be one of the safest on the market, and also does not use cobalt, nickel and manganese. It is expected to have a lifespan of up to 3,000 cycles, or up to 900,000 kms. The battery can be recharged quickly at outlets of up to 75 kW.

A total range of up to 305 kms is claimed, with additional range provided by the solar panels which is a weekly average of 112 kms (245 kms per week at peak). There are 248 solar cells on the roof which can generate peak power of up to 1.2 kW.

“The growing EV market is generating enormous demand for longer-lasting, more sustainable batteries. This enhanced battery enables Sion drivers to extend the time between charges, whilst reducing the charging time itself. This effectively optimizes the Sion to deliver easy and affordable sustainable mobility for everyone,” said Markus Volmer, Chief Technology Officer at Sono Motors.

The company has also developed its own wall charging station or Wallbox which will be affordably priced. Being bi-directional, it can be used for home charging of the Sion as well as for supplying electricity from the car for use in the home or even to transfer to the local power grid. The Sion is thus a mobile powerplant that can not only reduce costs for home-owners but can also provide power during emergencies when supply is cut.

Older motorists will recall the days when they used to carry out simple maintenance tasks themselves. Today, however, there is less to do and most of the time, maintenance is done at service centres. Sono Motors intends to bring back the ‘DIY culture’ with the Sion to keep running and repair costs as low as possible. Standard replacement parts can be changed by the owner but for work involving high-voltage parts (which can have some risk), owners will be advised to send their car to authorized service centres.

The interior has a simple functional layout like any of today’s hatchbacks. Two tablet-style displays provide information on the car’s operation as well as the infotainment system. A unique design feature on the dashboard is the insertion of Icelandic moss, said to offer certain health benefits. The owner can connect to the car via Apple Carplay or Android Auto, and the Sono app allows remote control of the air-conditioning system or to check the battery status.

If everything goes according to plan, the first customers will get their cars sometime in 2023. To date, the company says over 15,000 orders have been received (along with downpayments) for the car which is to be priced from 28,500 euros (about RM132,000).

Free sunshine helps Proton save up to RM5.85 million on electricity costs