Throughout the 1980s, Toyota’s engineers worked hard to develop a hybrid system which could be commercialised and used in mass production. They succeeded by the end of the decade and the carmaker introduced its first model with a hybrid electric powertrain – the Prius. Since then, Toyota has continued to make ever better hybrid powertrains as new technology has been developed and more importantly, battery technology has also made much progress.

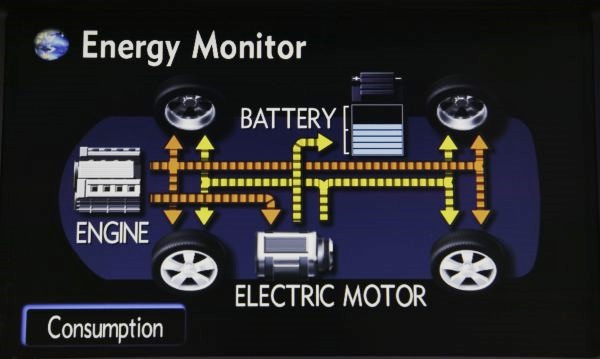

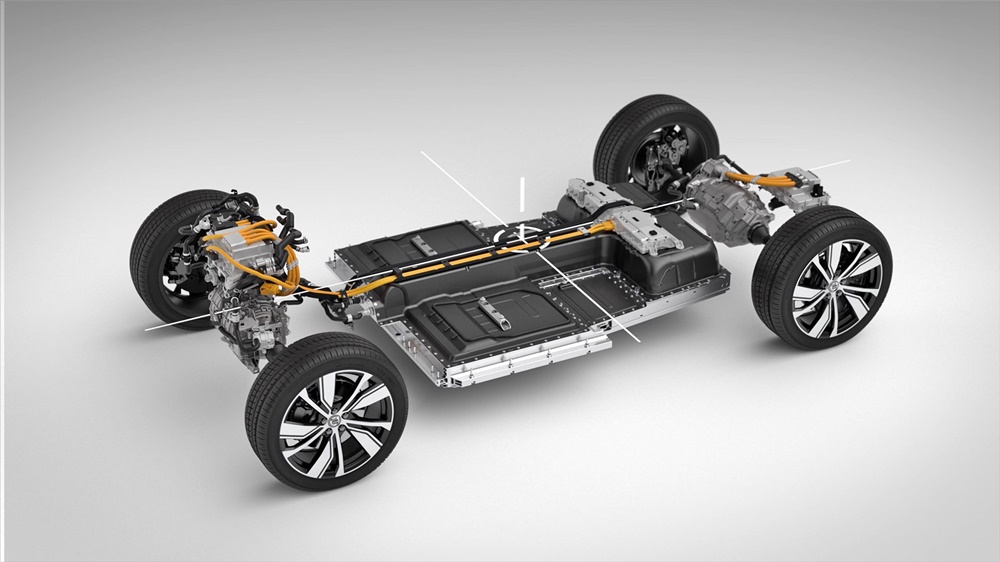

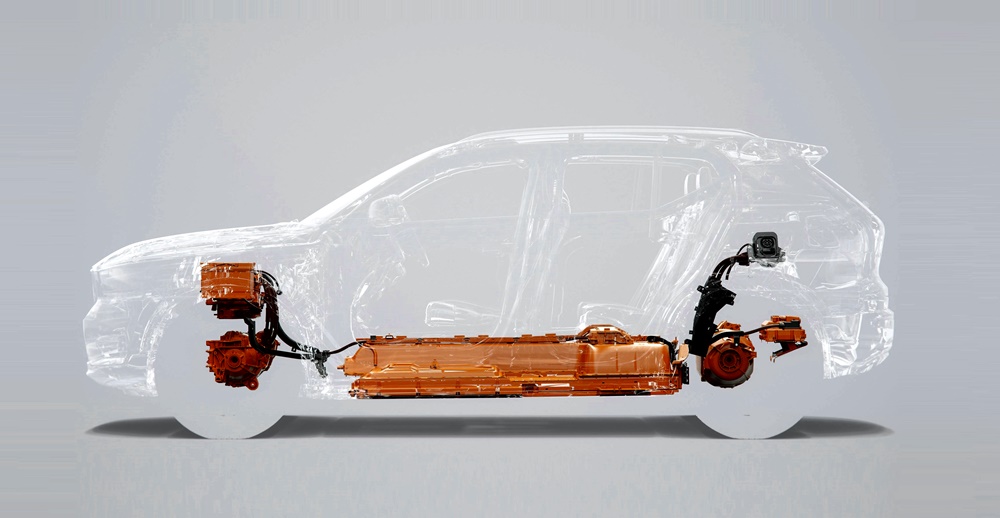

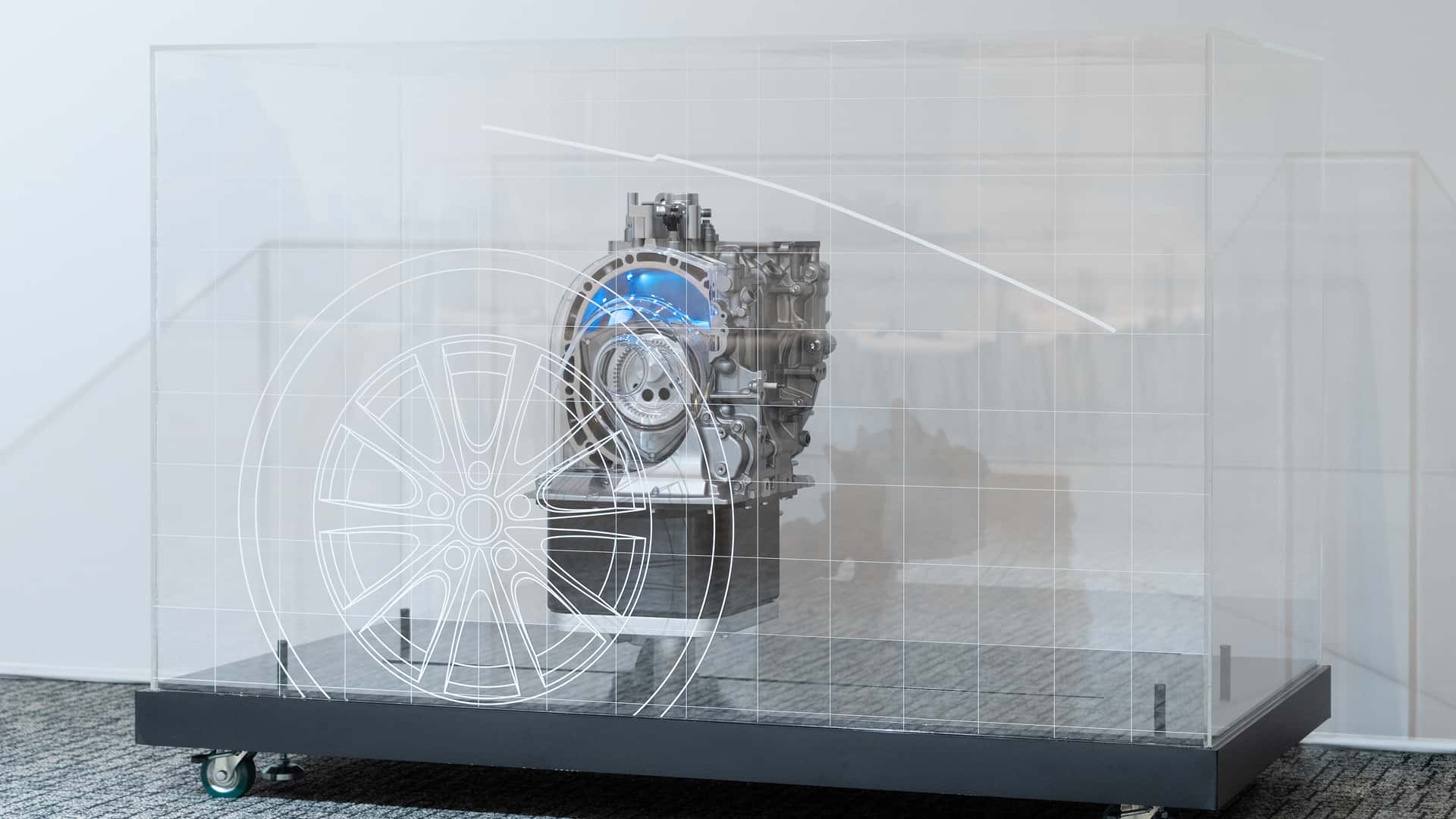

The hybrid concept is an ingenious marriage of an internal combustion engine and an electric motor. Their performance – in unison or individually – is governed automatically and seamlessly by an intelligent system that draws power from the appropriate source to maximise efficiency, or performance.

Electric power is generated by the engine while the car is being driven and is also converted from the kinetic energy produced when braking or slowing down. Power is stored in a high-voltage battery pack that needs no ‘plug-in’ recharging.

It started with the RX 400h

Lexus, Toyota’s premium luxury brand, has also been collaborating in the development of hybrid powertrains, apart from drawing on the development work done by Toyota. Years of R&D culminated in the RX 400h, the first self-charging hybrid Lexus and world’s first luxury hybrid vehicle, launched in 2005. On the outside, it looked little different from the familiar RX 300 SUV but, under the skin, things were very different. Yes, there was a 3.3-litre petrol V6 engine under the bonnet, but this was just one element in the all-new self-charging hybrid electric system.

The development of the Lexus Hybrid Drive brought ‘full’ hybrid technology to motorists. It meant the vehicle could run on electric power alone, with zero emissions and fuel consumption. Initially, this was limited to low-speeds and relatively short distances due to limitations in technology, especially battery capacity. But as the technology was developed, the capability increased significantly. Today, Lexus hybrids can travel up to 50% of the time in congested urban environments without the petrol engine running.

The second generation

The second generation of the Lexus Hybrid Drive showed significant progress. Not surprisingly, it was first offered in the brand’s new flagship sedan, the LS 600h, in 2007. As the first hybrid system to feature a V8 engine – a 5.0-litre unit, the most technically advanced Lexus had yet built – it delivered the kind of power and performance typically associated with a V12. The system delivered 445 bhp and 520 Nm of torque, giving acceleration from standstill to 100 km/h in just 6.3 seconds.

When it came to emissions and fuel economy, the LS 600h also broke new ground in its class. It could achieve official combined cycle fuel economy of 10.8 kms/litre and its comparatively low emissions earned it SULEV (Super Ultra Low Emission Vehicle) status in the USA.

A sportier dimension

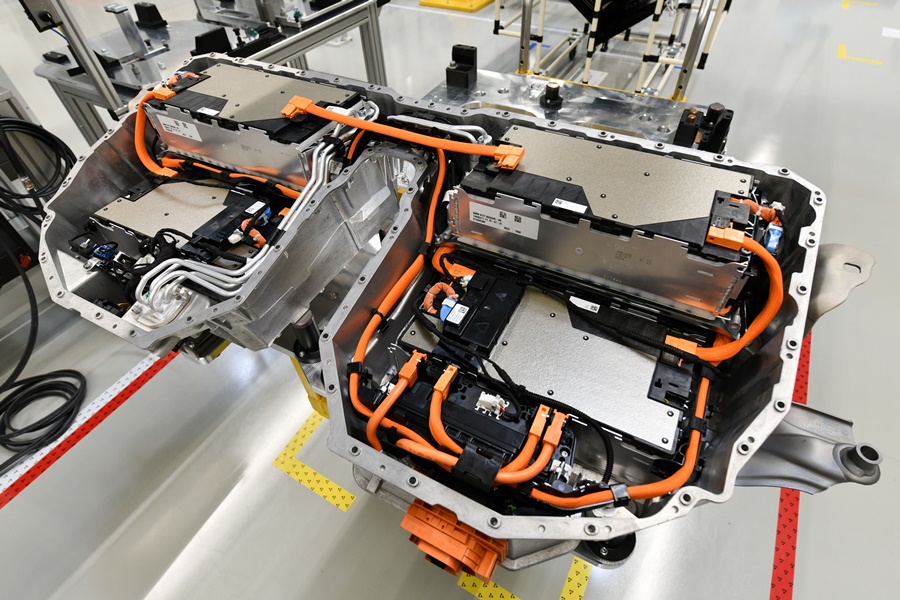

A sportier aspect of hybrid power was also seen in the GS 450h sports sedan. A 2-stage motor speed reduction planetary gear was used in both the GS and LS models but for the LS 600h, the hybrid transmission was upgraded. The nickel-metal hydride battery produced 280V, but a boost converter could ramp this up to 650V.

The GS 450h and the RX 450h, which superceded the original RX 400h in 2009, were equipped with a new 3.5-litre V6 engine. Thanks to the use of an electronically-controlled power split device, the transmission operated like a continuously variable transmission (CVT) but with the benefit – for the first time in a hybrid – of a manual shift mode and AI-Shift that used artificial intelligence to adapt performance to the driver’s style and the driving conditions.

More efficient, more responsive

The third generation of Lexus Hybrid Drive made advances both in efficiency and responsiveness. The revised system was first seen in the IS 300h, the first IS to feature hybrid power, which entered the market in 2013.

Central to the improved performance was a new 2.5-litre Atkinson cycle petrol engine, equipped with D-4S direct fuel injection, Dual VVT-i intelligent variable valve-timing and a high-efficiency exhaust gas recirculation system. Combined with the hybrid transaxle, this gave class-leading, sub-100 g/km CO2 emissions and fuel economy from 23.3 kms/litre.

With further refinements, this system was also adopted for the Lexus NX, the company’s first midsize crossover, and the RC 300h coupe, both of which joined the range in 2014.

The Multi-Stage Hybrid System

While the styling of the LC Coupe has earned it high praise and awards, the LC also marked a new era in hybrid electric technology. The breakthrough was the Multi-Stage Hybrid System, a new transmission device that retains the hybrid’s efficiency, but which takes the driving experience to a higher level.

The LC 500h is equipped with a 3.5-litre V6 engine that revs all the way to 6600 rpm, and benefits from detailed engineering features to promote both performance and efficiency. The Multi-Stage Hybrid System allows its potential to be exploited to the maximum by amplifying the output of both the engine and the electric motor. In this way, performance can be optimised at all engine speeds.

For the driver the rewards are more responsive and direct acceleration, greater dynamic performance and all-round driving pleasure – the ‘even sharper’ character that Lexus sought to achieve. With total system output of 359 bhp and 0 to 100 km/h acceleration in a claimed 5 seconds, the new powertrain fully justifies its place in a performance model, yet can go up to 12.3 kms/litre. Since its introduction in the LC, the Multi-Stage System has also been used in the LS 500h.

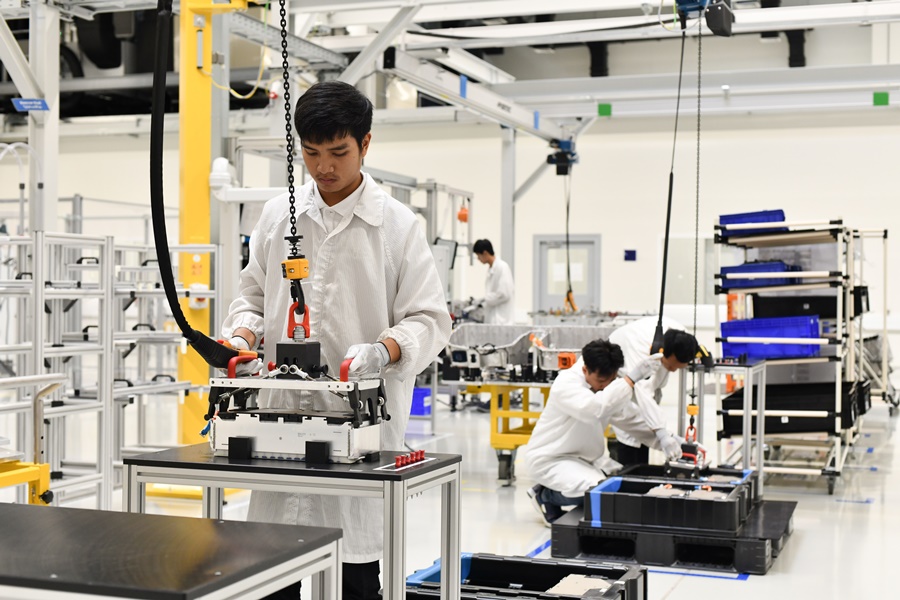

Aiming higher with fourth generation

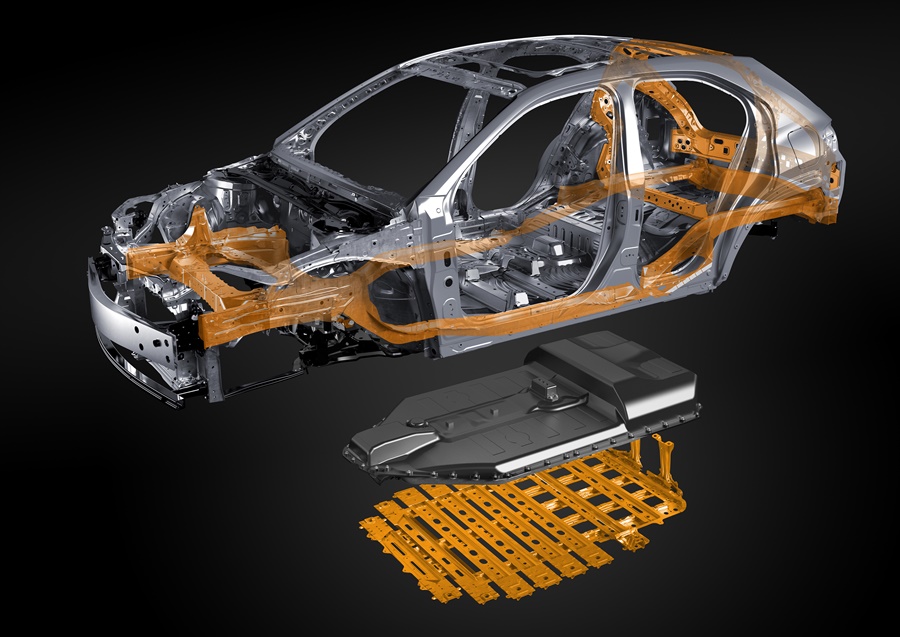

Today, Lexus is leveraging its technology leadership with a fourth generation of Lexus Hybrid Drive that achieves even better fuel efficiency, responsive emissions and low emissions. Featured in the new ES 300h sedan and UX 250h compact crossover launched in early 2019, it combines the benefits of an all-new, ultra-efficient Atkinson cycle engine with a new electric motor that’s lighter, more compact and more power dense.

No effort was spared in this powertrain’s development, with 60 prototypes built and more than 10 million kilometres of road testing carried out. The result is the most thermally efficient engine yet to be installed in a production vehicle – rated at 41%. This means more of the power potential of every drop of fuel is captured to drive the wheels. This has been achieved with fast-burn combustion technology that ensures more power is gained without increasing emissions or fuel consumption.

Proven, robust and reliable technology

Lexus hybrids proved themselves to be intrinsically quiet, smooth and refined and, as the years passed, they also demonstrated exceptional reliability. This is not a fragile technology, but a robust and highly durable solution.

Within 15 years, Lexus has made the hybrid concept central to its brand, extending its reach from a single model in 2005 to a range of up to 10 vehicles in some regions today, covering many different bodystyles and performance levels. Worldwide, cumulative hybrid sales have passed 1.6 million units, while in Western Europe hybrids now account for 99% of all the new Lexus vehicles sold in the region.

To know more about Lexus models available in Malaysia, visit www.lexus.com.my,