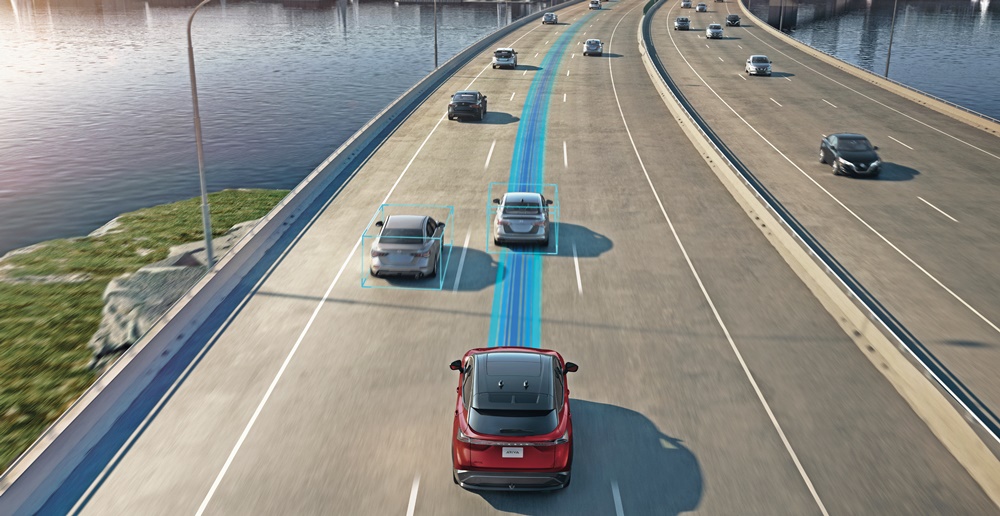

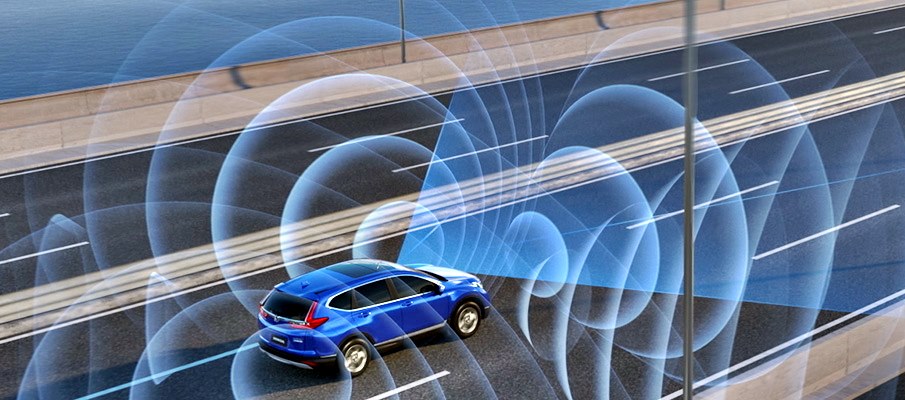

In the near future, people will be able to travel in cars without humans having to be in control. Perhaps it can no longer be called ‘driving’ if there is no human involved and it is just ‘mobility’. Such autonomous vehicles are already in existence and will grow in numbers.

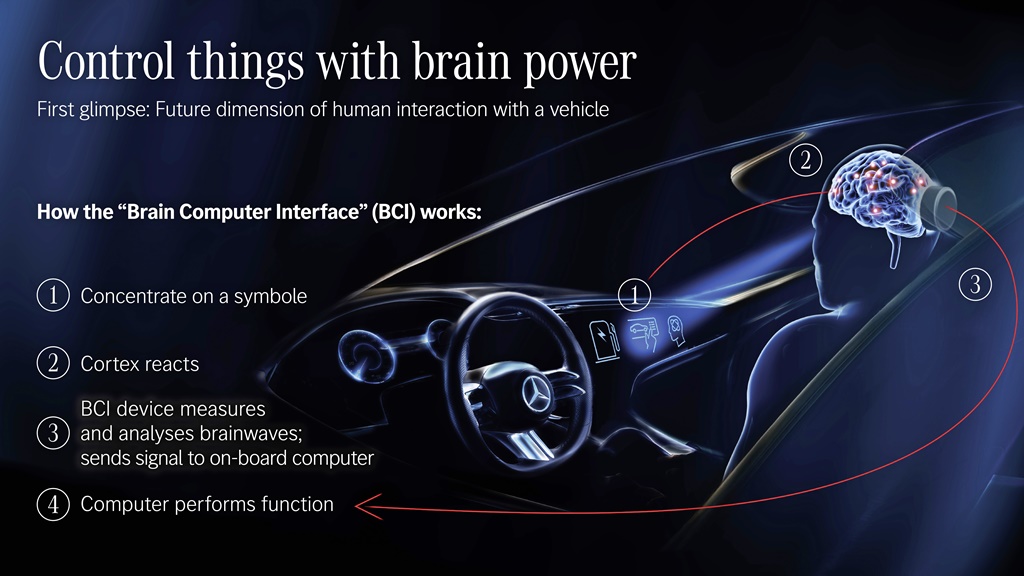

In looking ahead, Mercedes-Benz also sees way into the future where there could be new dimension of human-vehicle interaction: brain-computer interface (BCI) technology. It sounds like science fiction and it is, but some parts of the technology are already available. BCI will be a new form of machine control, perhaps not in everyday life tomorrow but in areas like medical research. Applications with BCI are considered a viable option for helping people with physical handicaps to become more independent.

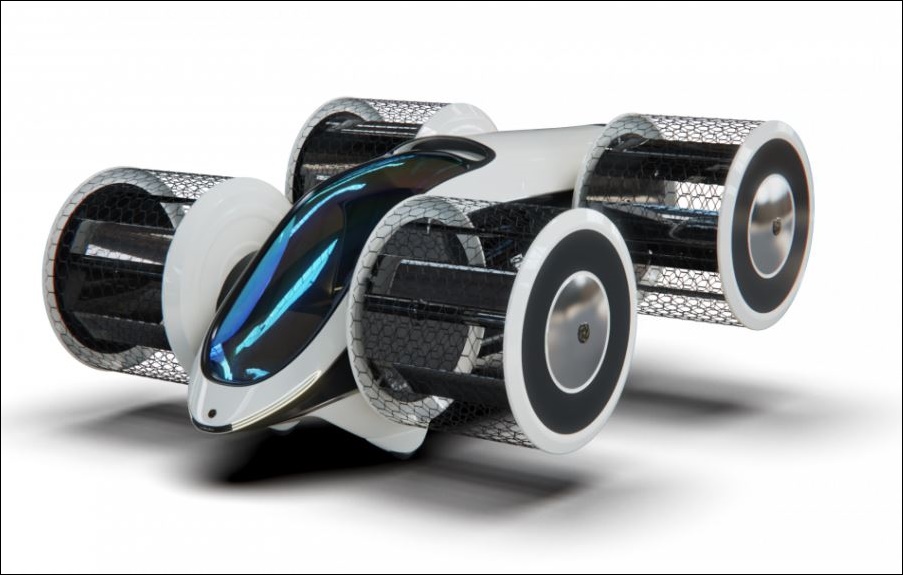

Integrated with VISION AVTR

Mercedes-Benz is also looking at the possibility of BCI with vehicles and has integrated it in the VISION AVTR concept vehicle which it first displayed in January last year. It will give a preview of mind control as a new dimension of human interaction with the vehicle. This will use a BCI device attached to the user’s head analyzes the measured brainwaves and triggers a defined function. At the IAA Mobility 21 event in Germany recently, visitors were able to experience controlling the user interface in the vehicle with their own thoughts and interacting with it in real-time.

“Mercedes-Benz is setting another milestone in the merging of man and machine with the research and development of brain-computer interface applications in cars. BCI technology has the potential to further enhance driving comfort in the future, for example,” said Britta Seeger, Member of the Board of Management of Daimler AG and Mercedes-Benz AG, responsible for Sales. “Mercedes-Benz has always pioneered intelligent, innovative solutions to provide our customers with the best product and service experience. BCI technology works completely independently of speech and touch. This opens up revolutionary possibilities for intuitive interaction with the vehicle.”

Directly connected to the brain

The biometric interaction with the vehicle is complemented by a direct connection to the human brain. At the IAA, the first approaches to mind control based on visual perception will be demonstrated in the visionary seat mock-up of the VISION AVTR. For this purpose, light dots are projected onto the fully digital dashboard. A BCI device with wearable electrodes attached to the back of the user’s head records brain activity and establishes a direct connection to the vehicle after a one-minute calibration. The brain reacts to the visual stimuli on the dashboard.

The BCI device measures the neuronal activity at the cortex in real time. It analyzes the measured brain waves and recognizes on which light points the user directs his focus and full attention (attention-sensing interface). The stronger the focus, the higher the neuronal activity. The device then triggers the targeted function in the vehicle.

Using several functions linked to BCI technology, visitors experienced how quickly their own brain connects with the vehicle – similar to the neuronal connection between the Na’vi and the nature in the visionary Hollywood blockbuster ‘AVATAR’. By focusing on points of light, they used the power of their thoughts to perform various functions in the digital VISION AVTR worlds displayed on the dashboard: for example, generate wind, grow plants, select parking spaces to charge or turn day into night.

Concept vehicle developed with Disney

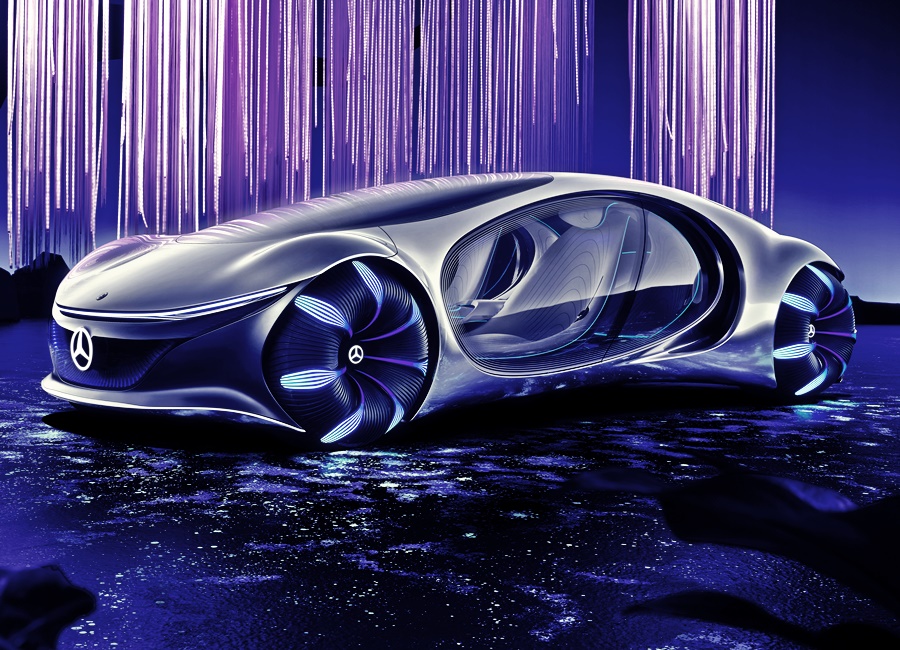

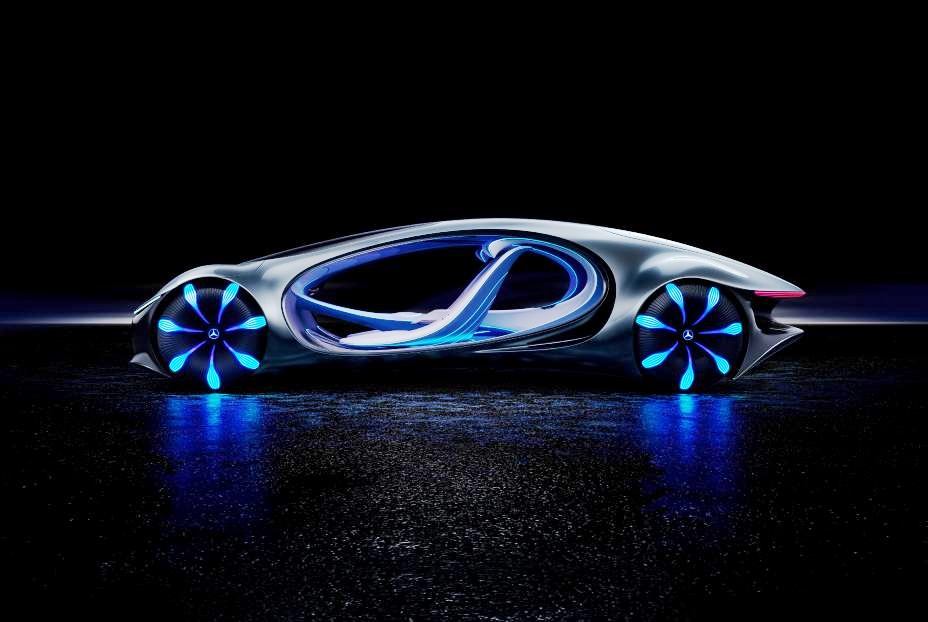

The VISION AVTR was previous presented at the 2020 CES in Las Vegas. It was the result of an extraordinary global collaboration between entertainment company Disney and Mercedes-Benz. The name of the concept vehicle stands for ADVANCED VEHICLE TRANSFORMATION which looks at mobility in the distant future.

The stretched ‘one-bow’ design and organic design language combine exterior and interior into an emotional whole. Sustainable materials such as vegan DINAMICA leather made from recycled materials, fast-growing Karuun (rattan) that can only thrive in biodiversity, and organic, compostable battery technology create a closed-loop economy.

33 bionic flaps on the back of the vehicle can communicate with the outside world – with and through the driver – using naturally flowing movements in subtle gestures. Instead of a conventional steering wheel, the VISION AVTR has a multifunctional control element in the centre console. By placing the hand on the control, the interior comes to life and the vehicle recognizes the passenger by their heart rate. Simply raising the hand projects a menu selection onto the palm of the hand, allowing the user to intuitively choose between different functionalities.

The biometric connection enables a completely new interaction between man, machine and nature in the autonomous-driving concept vehicle. Continuing development of the ‘Hey Mercedes’ voice assistant and the zero-layer concept of the MBUX Hyperscreen have already simplified vehicle operation. In future, BCI technology could make it possible to relieve the user even more, in order to be able to focus on the driving experience.