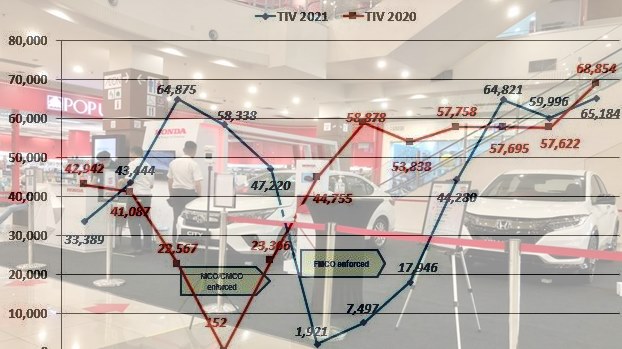

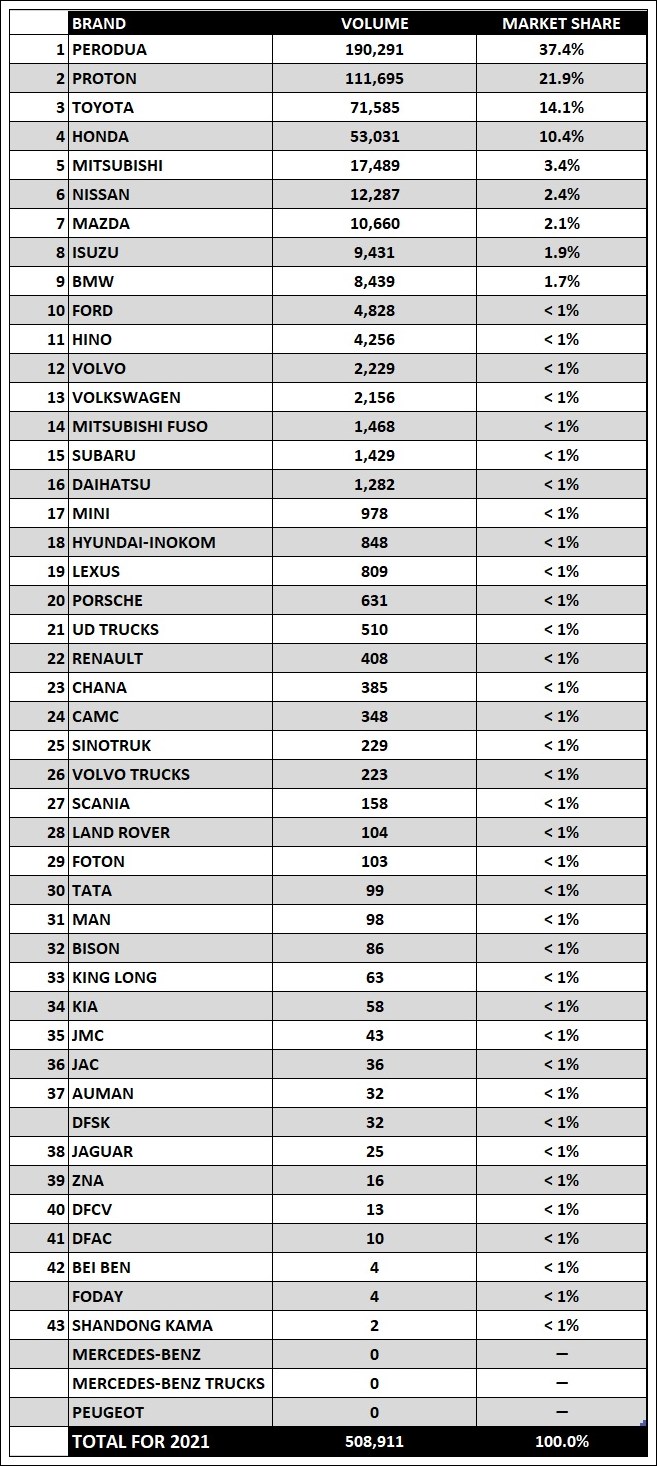

After two difficult years with disruptions caused by the COVID-19 pandemic, and then the global semiconductor shortage which started last year, Perodua is looking towards a stronger recovery in 2022. The Malaysian carmaker delivered 190,291 vehicles in 2021 – 13.6% lower than the volume reported in 2020 – but has set a target of 247,800 units for this year.

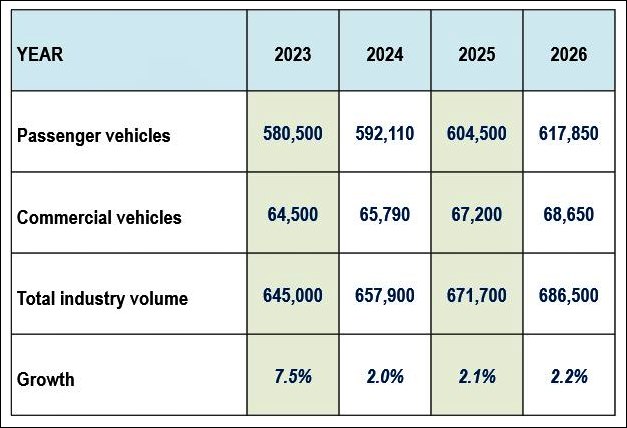

Speaking to the media during the annual press conference today, Perodua’s President & CEO, Dato’ Zainal Abidin Ahmad, said that this volume would amount to around 40.6% market share, based on Perodua’s own forecast of 610,000 units which is a bit higher than the 600,000 units forecast for 2022 by the Malaysian Automotive Association (MAA) recently. In 2021, Perodua, as market leader again, had a 37.4% market share.

Production target of 265,900 vehicles

With the target set at 247,800 units, Perodua plans to produce 265,900 vehicles during the year, which is 37.5% higher compared to 193,400 vehicles produced in 2021. The number is higher as the company produces extra as ‘buffer stock’ in case there are disruptions in production. The increase in production would also result in an increase in locally-sourced automotive parts by 41.5% to RM7.5 billion as compared with the RM5.3 billion purchased in 2021.

Commenting on the performance of 2021, Dato’ Zainal said the year was challenging as the country and its main industries had to cope with various crises throughout the year. “Demand remained strong for all our models with the Myvi leading the list with 47,525 units, followed by the Axia with 43,080 units, Bezza with 42,698 units, Ativa with 26,847 units, Aruz with 15,313 units and the Alza with 14,828 units,” he said.

Dato’ Zainal explained that the sales tax exemption initiative introduced by the government is still an excellent incentive for the consumer to purchase new cars. It was extended until June 30, 2022 and Perodua is hopeful that it might be extended again, which would have a positive effect on sales.

“Our order book for new vehicles is still quite healthy with the guarantee that the production will go uninterrupted will mean that we could fulfil the outstanding orders in a timely manner,” he said, adding that assurances by the government that the measures of containing the pandemic is showing success that another lockdown would not happen.

“With that being said, we have learnt a lot from this situation and have incorporated effective counter-measures to ensure that we will be able to face them better if they re-occur,” he said.

Over RM1 billion investment

During 2022, Perodua’s investments will go pass the 1 billion ringgit mark to RM1.326 billion. The development of a new model will take the biggest chunk of RM529.1 million, with improvements to manufacturing facilities and processes taking RM321.3 million.

Perodua will also spend RM46.6 million on digitalization which it sees as being very important in view of trends that show consumers making more use of online and digital services. This will encompass the entire company as well as its dealers and vendors and for customers, the initiative will be seen in the development of a Connected Vehicle as well as e-Manuals and more extensive use of online communications.

The digitalization move will also see the retail network being changed. Just as the banking industry has seen a steady reduction in branches over the past 10 years, Perodua’s outlets will also be adjusted accordingly. Nevertheless, physical showrooms will still exist even though online channels have been made available for communications and sales enquiries.

Upgrading dealerships

Additionally, the existing 1S/2S outlets will be upgraded to 3S outlets that provide a full range of sales and aftersales services to customers. Perodua is encouraging the small dealers to have a more entrepreneurial attitude and develop their businesses further so they can enjoy greater success. In fact, there is a special programme for this which 56 dealers are participating in to learn entrepreneurial skills, knowledge and business survival.

Exports over the past two years have been minimal due to the pandemic and as some of the overseas markets remain closed, no vehicles have been sent. However, some shipments have been made to Singapore, Brunei and Indonesia though they have been small in number. The company is interested in exports but not as a primary business. It also wants to ensure that wherever it exports to, it will have a proper understanding of market conditions and customer requirements to ensure that the products are right and can be well accepted.

Aiming to be regional production hub

While Proton has stated its aim to be a strong regional player in time to come, Perodua is aiming to become a regional hub, not in vehicle sales but in R&D. Since it started in 1993, it has been steadily building up its R&D capability which accelerated when the 2000s began. Its involvement in the development of the first Myvi, which was jointly developed with Daihatsu and Toyota, was a great opportunity to learn and today, Perodua has full capability for upper body development.

It has been given increasing responsibilities by Daihatsu in development work for ASEAN products and Perodua personnel have even been assisting Daihatsu in Indonesia in some product development work. Dato’ Zainal said that it is possible Perodua could eventually become the R&D hub in ASEAN for Daihatsu. This would be something like Toyota having moved its R&D activities for the Hilux out of Japan to Thailand (although in that move, it was to its own subsidiary).

Perodua EVs?

On the move towards electric vehicles, Dato’ Zainal sounded positive towards the aims of the government to shift towards electrified vehicles in the effort to address climate change. However, Perodua is still studying the matter to determine what approach to take and is having discussions with Daihatsu as well. “What is important is that if we offer electric vehicles, they must be affordable for Malaysians as that is what Perodua has always strived to do,” he said.

Perodua offers assistance to flood-affected customers with 50% discount on selected parts