The Toyota Eco Youth (TEY) program, organised and managed by UMW Toyota Motor (UMWT) for the past 19 years, will continue into its 20th edition with a longer program. Unlike previous years which have been completed within a year, the concept for this year’s TEY program is that it will run for 3 years. For this 20th edition of TEY, the winners will return as facilitator in the 2nd year to mentor the new batch and establish a TEY Apprentice Online Club. The winners will then continue with proof of concept and Intensive Prototype Development.

283 teams registered to participate

To date, it has involved 258 schools, 1,910 secondary school students and 762 teachers throughout the country. The program is open to secondary school students aged 13 – 16 years old and there is unlimited school participation. For this year, 283 teams from 177 schools have submitted registrations but only a maximum of 16 teams from schools will take part.

“The Toyota Eco Youth has been running continuously for 20 years and we hope that those who have participated continue to grow their creativity help propagate a greener future for all of us,” said Akio Takeyama, Deputy Chairman of UMW Toyota Motor.

For the 20th edition of TEY, UMWT is again collaborating with the Ministry of Education and will run state and national level competitions. Additionally, for this year, the Leaderonomics Community also joins as a working partner.

Activities conducted online

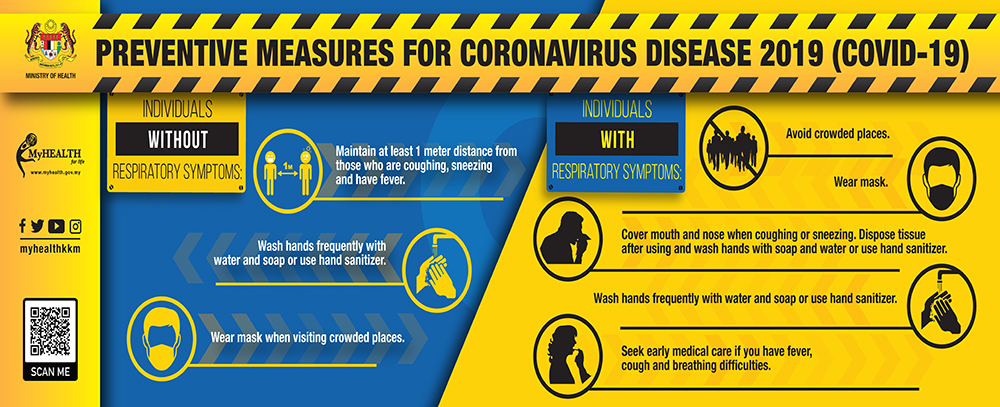

In view of the present COVID-19 pandemic situation, the official launch of the National-level competition took place online recently. UMWT Executive Director of Sales, Mohd Shamsor Mohd Zain, announced the teams which come from all over the country, including Sabah, Sarawak and Labuan.

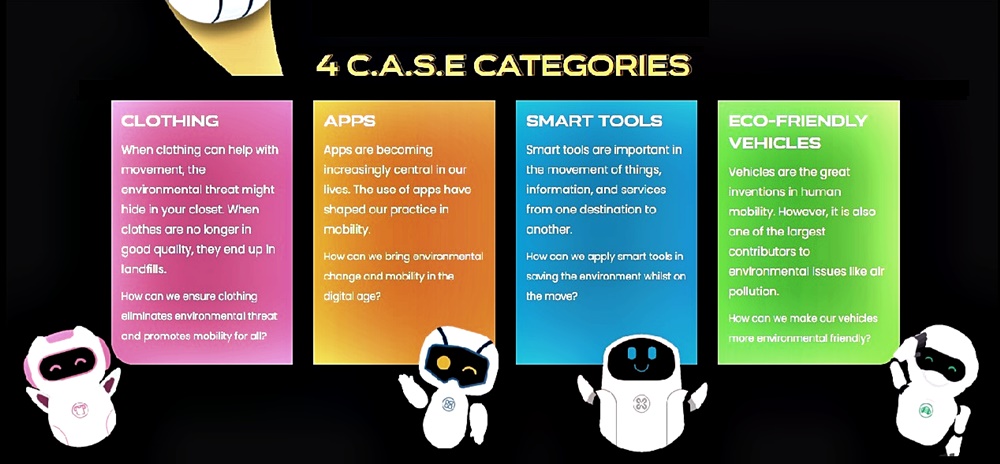

Encik Mohd Shamsor also introduced Agent M (Mobility), consisting of 3 – 4 members per team. Each Agent M will select a C.A.S.E. (Clothing, Apps, Smart Tools or Eco-Friendly Vehicles) and present solutions to environmental issues. Their solutions will be presented in a video uploaded for judging and public viewing.

‘Reimagining Mobility’ is the theme

The format of this program will be fully online, and the 16 teams will be equipped and trained with project management skills that incorporate Toyota’s Problem Solving Methodology. They will then be required to build a prototype solution based on the theme of ‘Reimagining Mobility’. This theme depicts the creation of safe and eco-friendly mobility solutions for the nation with a dual-pronged approach to ensure that they are both theoretically and practically comprehensive which includes the interactive e-learning lessons and workshops.

The final judging phase will require the team to showcase their progress through social media and livestream channels. The prize money has been doubled with the total pool of cash prizes amounting to RM64,000.

“Since the inception of Toyota Eco Youth, UMW Toyota Motor has spent over RM7 million on the program,” said Ravindran K., President of UMW Toyota Motor. “In spite of pandemic, we will not diminish our support for such programs as they are an important part of our Corporate Social Responsibility.”

For further information on the 2020/2021 Toyota Eco Youth Program and updates, the public can visit www.toyota.com.my/toyotaecoyouth.