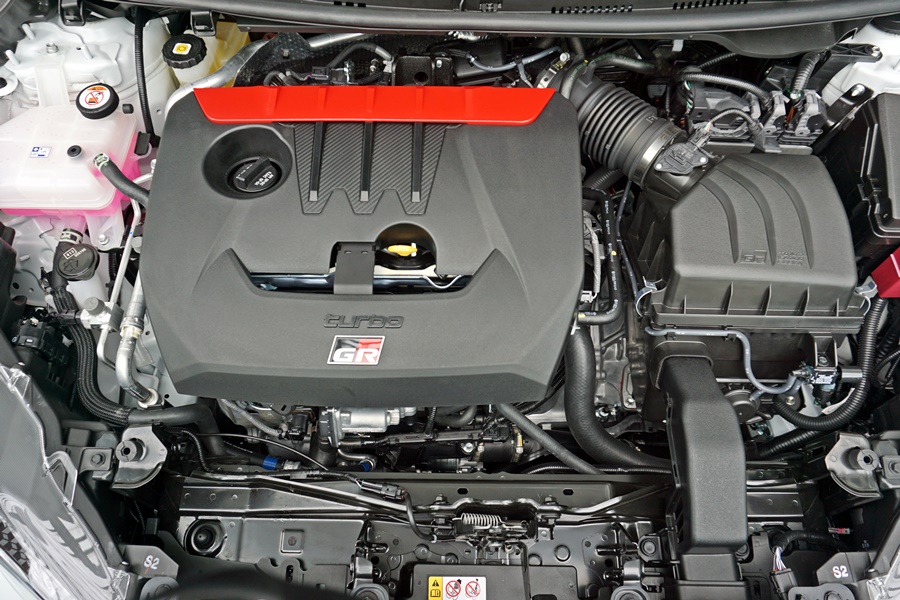

Honda Malaysia has introduced an upgraded range of Genuine Engine Oils, recommended specially for Honda vehicles, of course. The oil now has an API SP grade which provides stable performance and better fuel economy while prolonging engine lifespan as well as offers greater engine protection.

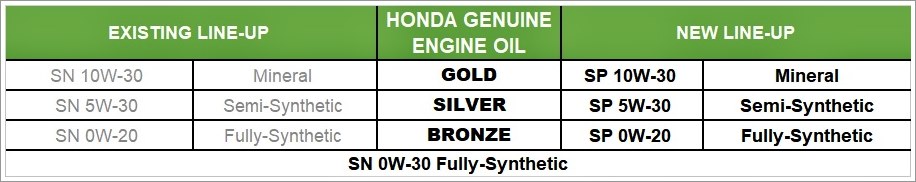

The new engine oil will replace the existing SN Grade range with mineral (Bronze), semi-synthetic (Silver) and fully synthetic (Gold) formulations. However, the SN grade 0W-30 viscosity fully-synthetic oil will still be available for cars with high performance engines such as the Civic Type R.

Suitable to be used for most petrol and turbocharged engines, the SP Grade engine oil is approved and recommended by Honda Research & Development (R&D). The new engine oil range is formulated to fulfil all operating requirements of Honda engines and also meet the latest standards issued by the American Petroleum Institute (API). It enhances protection against low-speed pre-ignition, an abnormal combustion phenomenon that can cause significant damage to the engine.

The SP Grade engine oil also comes with a timing chain wear protection to minimise timing chain elongation. In addition to improved high temperature deposit protection for pistons and turbochargers, it provides better sludge and varnish control, valve train and intake lifter wear protection, higher oxidation stability as well as emission control system protection. The lower-viscosity of 0W-20 fully-synthetic oil allows the engine to operate with maximum efficiency while very good protection for key engine components, even at extreme temperatures.

More information on the new Honda engine oil is available at any authorised Honda service centre, or at www.honda.com.my.

Why use a Genuine Oil?

There are engine oils and there are Genuine Oils but to the average motorist, it is hard to understand what can be so special about Genuine Oils sold by some car companies. It may seem like such products are created just to give the car company an extra source of revenue by using the brand name. After all, an oil is an oil, right? As long as it is from a reputable producer and meets the requirements of the carmaker (specified in the Owner’s Manual), it should be okay to use.

You won’t go wrong picking an oil produced by any of the reputable oil companies, but you may not get 100% lubricating performance with the engine in your vehicle. This is because each engine has its own characteristics and design features; some may have unique combustion chamber designs, more complex valvetrains or special oil passages. These are known to the engineers who design the engines but may not be understood by those in the oil companies who try to come up with an oil which ‘suits all engines’.

This is where the specifications for a Genuine Oil come in and they may have specific requirements to ensure proper lubrication in certain areas. In other words, the Genuine Oil will have a unique formulation which will work best with the engine for which it is recommended, and it will perform better than other oils [for that engine].

More customized for specific engines

The best analogy to this issue would be to think of clothes. You can go to a department store and buy a shirt with a famous brand name. You may get a choice of S/M/L/XL and one of the sizes will fit your body. Maybe you will be lucky and the sleeves will also be just the right length and the collar is not too tight. However, it is also possible that your arms may be just a wee bit longer and the sleeve length for size ‘M’ is not exactly matching for you.

Now you could also go to a tailor and made a shirt with a similar design but you would be able to have the sleeves just the right length to suit your arm and the collar will be comfortable instead of choke you each time you have to wear a tie. You feel comfortable wearing the shirt and its ‘specifications’ are exclusive to you.

That is basically the difference between a Genuine Oil and other oils: customization. While it may be that 99% of engine designs are similar, there may still be that 1% which is unique to each engine and only a Genuine Oil would be able to cover the lubrication needs of that 1% so you get optimum performance.

This is not to say you must use only Genuine Oil for your vehicle and that other oils are not good enough. As a consumer, you always have choices but as a Honda owner, if you want to give your vehicle the best at all times, then Honda Genuine Engine Oil would be the best to use.

Honda Insurance Plus owners can get up to RM1,500 allowance if their vehicle was damaged by floods