Everyone is going electric and so will Mercedes-AMG, the high-performance subsidiary of Mercedes-Benz AG. And it is no longer a change that will take place in the next decade – stricter regulations have forced carmakers to act quickly and most have already a few fully electric models on sale, with more in the pipeline during this decade.

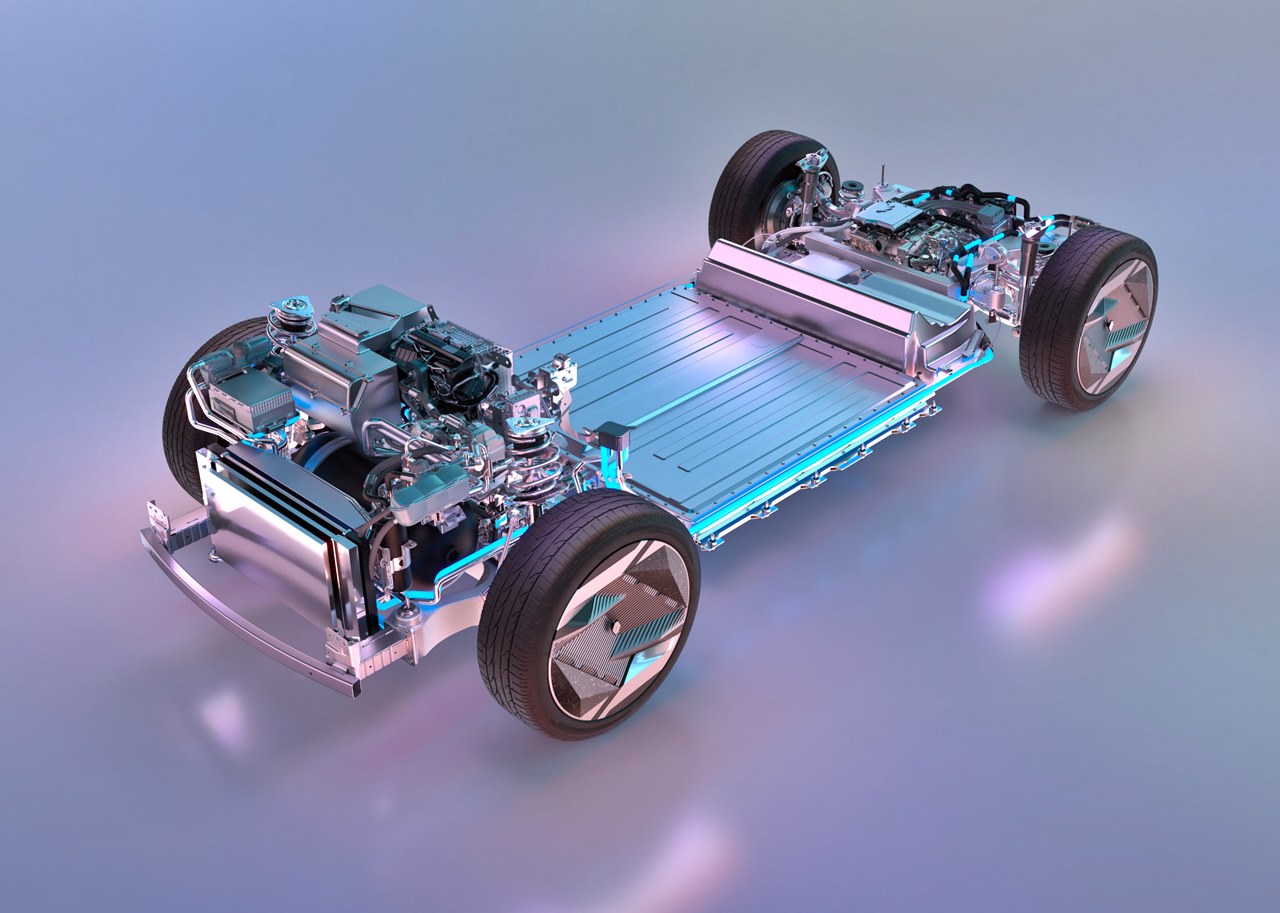

At Mercedes-AMG, it’s not just about switching to electric powertrains but doing so while retaining the high performance which the brand has built its reputation on. “We’re developing everything from scratch, from the dedicated AMG.EA platform to the revolutionary drivetrain technology with which we will take performance electric mobility to a whole new level,” said Philipp Schiemer, CEO of Mercedes-AMG GmbH.

“AMG is reinventing itself. As was once the case with our founding fathers, there has been an amazing feeling of new beginnings here in Affalterbach [the home base of AMG] for quite some time now. The course has been well and truly set for an electrified future, and we’ve set the bar high. That’s because our customers expect something very special from all-electric cars. We have already well and truly proven our expertise in this regard with the SLS AMG Electric Drive, our own E PERFORMANCE hybrid technology and the first Mercedes-EQ derivatives,” he said.

To provide a glimpse of what its future high-performance products will look like, it has built the Vision AMG showcar. Like the Vision EQXX concept presented by Mercedes-EQ earlier, the Vision AMG is a design study which is not the basis for a future model though its technologies will be used in a new sportscar that will be out in 2025.

Monolithic sculpture

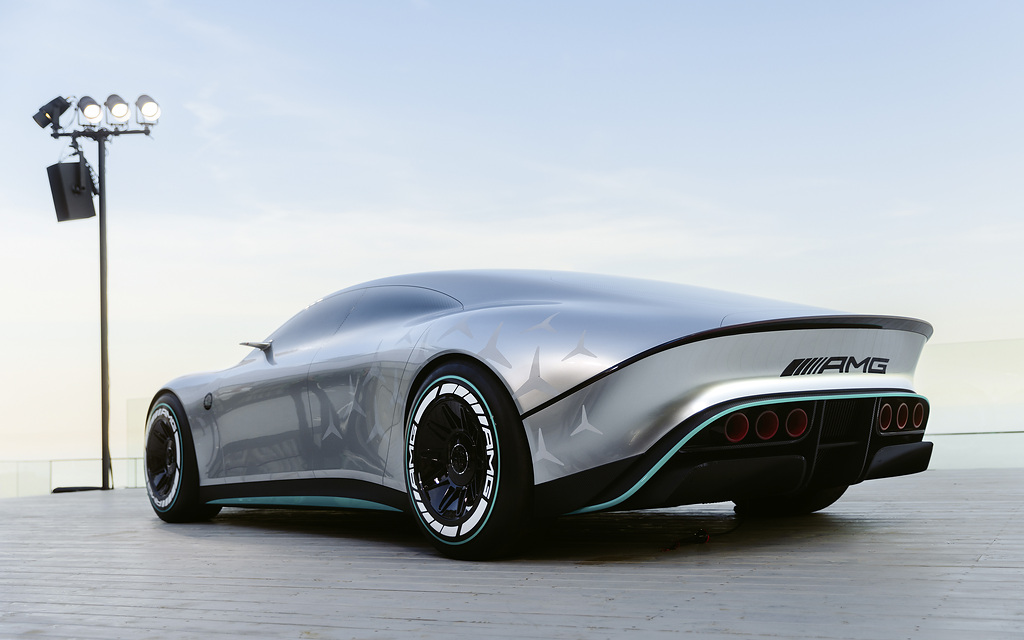

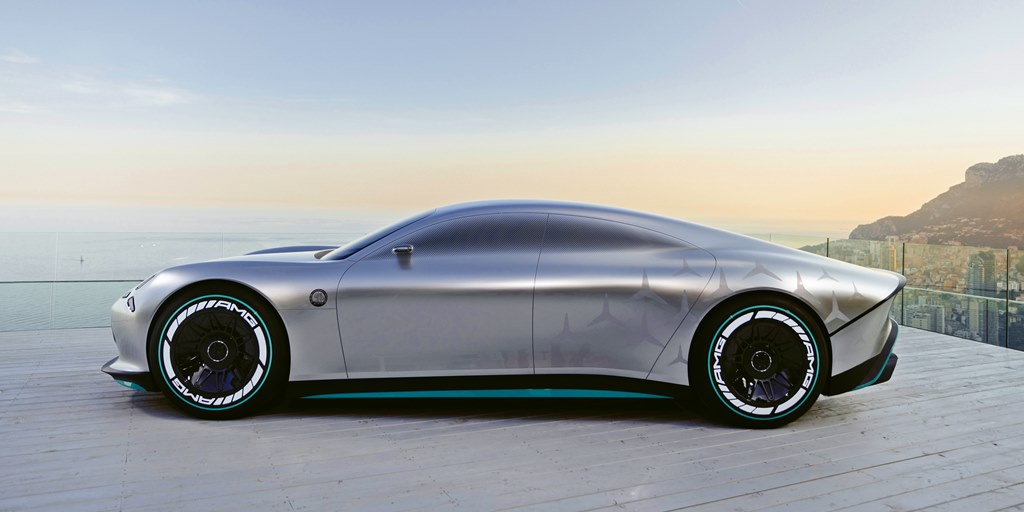

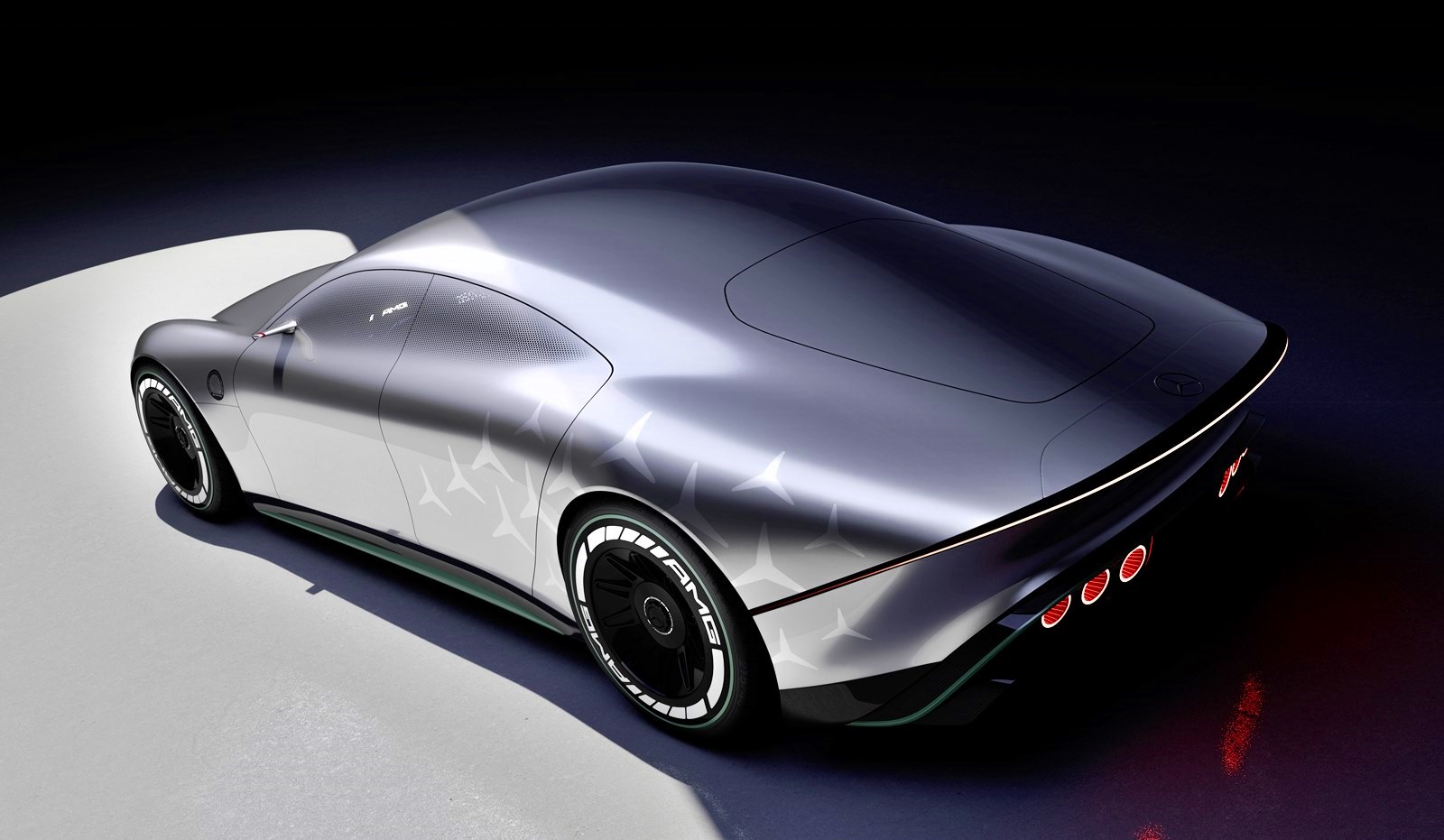

The proportions of the car are defined by a long wheelbase, and emphasised by short overhangs, powerful shoulders, large wheels, a distinctive rear spoiler and star-shaped headlamp signature. Joints and shut lines are reduced to a minimum, and the rear and side windows are painted in the same Alubeam silver as the car itself. The result is an overall look that reinforces the impression of a monolithic sculpture.

The graceful greenhouse is integrated into the flowing overall form and blends seamlessly into the low-lying silhouette. The roof tapers as its line drops elegantly towards the rear, flowing directly into the rear spoiler. The overall effect is a visually fascinating and aerodynamically advantageous teardrop form, not unlike that of the VISION EQXX.

The sharply angled tear-off edge at the rear incorporates an active spoiler, elongating the side view while at the same time improving the aerodynamics. It is framed by a precisely cut band of light that accommodates a variety of different light installations, providing an effective contrast with the large black AMG logo on the rear of the car.

Technical details are provided in general terms, with mention of a dedicated high-performance high-voltage battery pack and revolutionary drive technology. The powerful heart of the Vision AMG is its innovative Axial Flux Motor developed by Mercedes-Benz’ wholly owned subsidiary, YASA. With its compact and lightweight design, can deliver substantially more power than conventional electric motors.

Closed-off AMG grille

While an EV has no cooling requirements like a car with a combustion engine, the AMG grille with vertical bars is retained as a distinctive brand feature. The grille is therefore closed off, painted in body colour and fully integrated into the front end. As the visual focal point, the grille emphasises the futuristic look of the Vision AMG with its illuminated bars and three-dimensional exterior contour. The three-pointed star is positioned prominently on the bonnet.

Star-shaped light signature

The headlamp light signature is unique with 3 LED elements forming a stylised, three‑dimensional Mercedes star, ensuring the Mercedes and AMG branding is visible night and day. The two headlamps are visually connected via the horizontal band of light above the grille. This light band can display a variety of animations – ranging from a welcome signature to constant light.

The round lights at the rear have a light design that is new yet familiar. On each side, three LED rings are positioned in cylindrical tubes. Here, too, small stars link to the Mercedes brand. By way of contrast, the expressive rear diffuser is painted deep black.

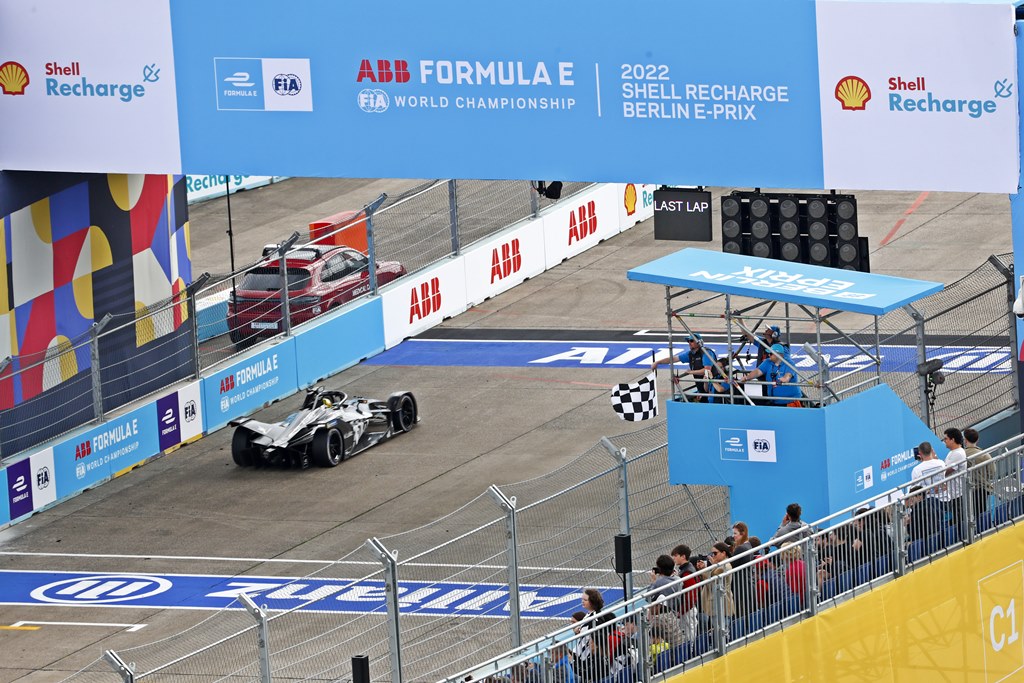

Connection to Formula 1

The Mercedes-AMG name is very prominent in Formula 1 with the Mercedes-AMG Petronas F1 team having won the world championship 8 times. The Vision AMG makes a direct connection in visual details. Examples are the silver paintwork with a large-format star pattern across the shoulders and rear wings; functional elements in exposed carbonfibre; the aerodynamic design of the 22-inch wheels with aero claddings; the AMG logo; and elements on the sills and diffuser in the PETRONAS colours.

30 years ago, the Mercedes-Benz F 100 showed the future of motoring