The automotive industry is changing faster than at any time in its history, with a convergence of trends and developments shaping the face of the sector beyond all recognition. Honda predicts that by 2030, the development of automobiles will be centred around electrification, automation and services. Environmental issues, such as climate change, are driving demand for cleaner mobility and accelerating the electrification of automobiles.

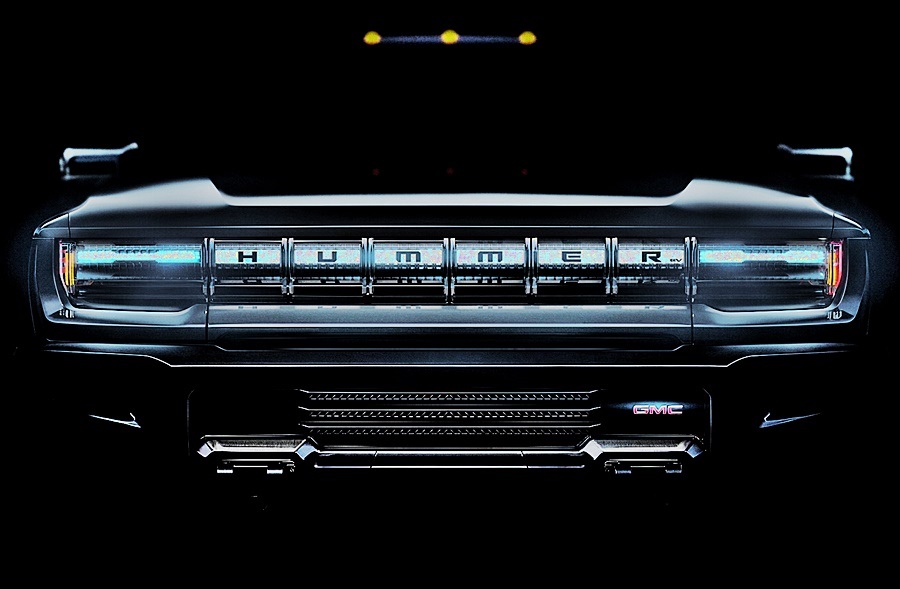

The new fully-electric Honda e is inspired by this 2030 prediction, engineered from the ground up to deliver a package perfect for the modern urban environment. It first appeared in concept form in 2017 as the ‘Urban EV’, followed by an almost production-ready prototype at the 2019 Geneva Motor Show.

Finally having its global debut in Frankfurt last year, the compact EV features cutting-edge technology and advanced intelligent connectivity to keep owners in sync with everyday life. The Honda e sets new technology benchmarks in the compact EV segment, with intuitive infotainment services and connected apps that seamlessly integrate with the owner’s modern lifestyle, accessed via the dual touchscreen displays, Honda Personal Assistant artificial intelligence or via the My Honda+ smartphone app.

Design-wise, the Honda e has a simple and clean modern appearance which somehow also brings to mind the original Civic. That Civic was a model of innovation in its time and the Honda e reimagines the identity of a small Honda for the next era of urban mobility.

Exemplifying such design philosophy is the Side Camera Mirror System (SCMS) that replaces conventional side view mirrors, with compact cameras that provide live images to two 6-inch screens inside the vehicle. The camera technology, a first in the compact segment, brings significant benefits for safety, aerodynamics and packaging.

The interior uses subtle, contemporary materials to create a relaxing lounge-like. The generous wheelbase allows passenger space comparable with that of cars in the segment above, with step-through access contributing to the spacious interior environment.

The Honda e also offers Single Pedal Control System to improve driving efficiency in urban environments. When activated, the system enables the driver to seamlessly accelerate, slow and stop the car using only the accelerator pedal. The Single Pedal Control System provides linear deceleration control that gives the car a more agile response. By decreasing in frequency the need to use both accelerator and brake pedals, it helps the driver feel more comfortable in stop/start congested city traffic.

The wide rear bench seat provides sofa-like seating, adding further to the ambience of a modern living space. Ceiling spot lamps above the occupants’ heads and out of direct eyesight contribute further to the comfortable and sophisticated feel, like you are switching on your living room light, and are activated by a button on the B-pillar.

The Honda e provides the most comprehensive range of driver aids in its class, addressing the demand for more safety provisions that is topping consumer expectations today. An enhanced suite of safety features sees the addition of three new safety technologies. These are Collision Mitigation Throttle Control, preventing sudden acceleration in either reverse or drive upon starting the car when there is an obstacle in the way; Low Speed Brake Function which applies emergency braking while driving at low speed, and Lead Car Departure Notification System which notifies the driver when the car in front has started moving.

Providing additional support to drivers is the Honda Parking Pilot, which continues the theme of user-focused technology. The system assists the driver in locating an appropriate space and then manoeuvring the car efficiently into it. It does this through the use of 4 cameras and 12 sonar sensors. A multi-view camera detects the white line of a parking spot, while the sensors recognise the actual parking space. The system can execute up to 5 parking patterns which covers virtually all parking scenarios.

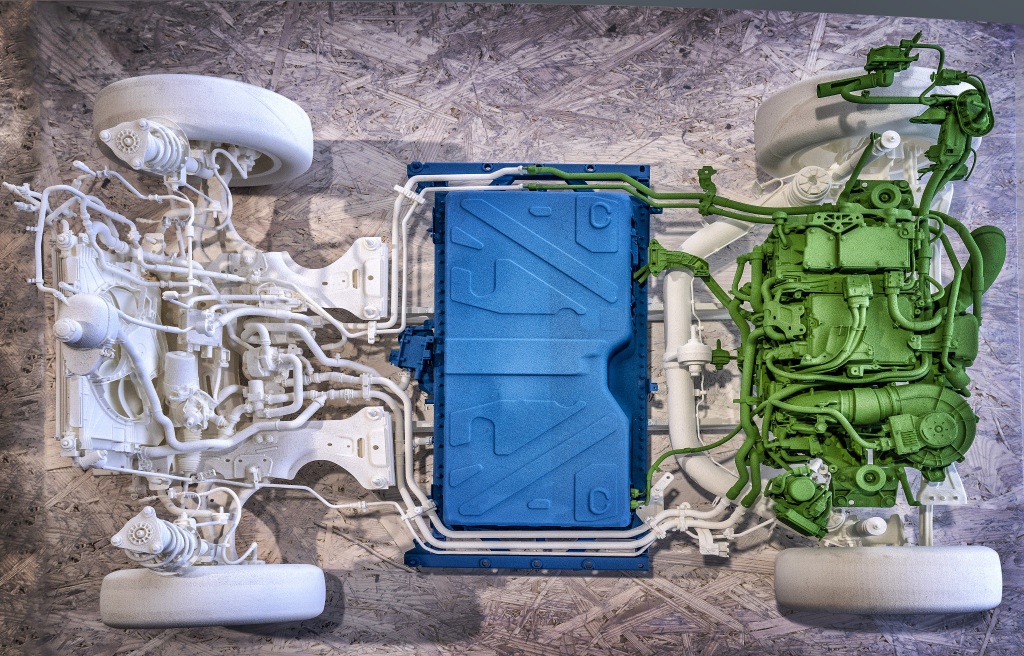

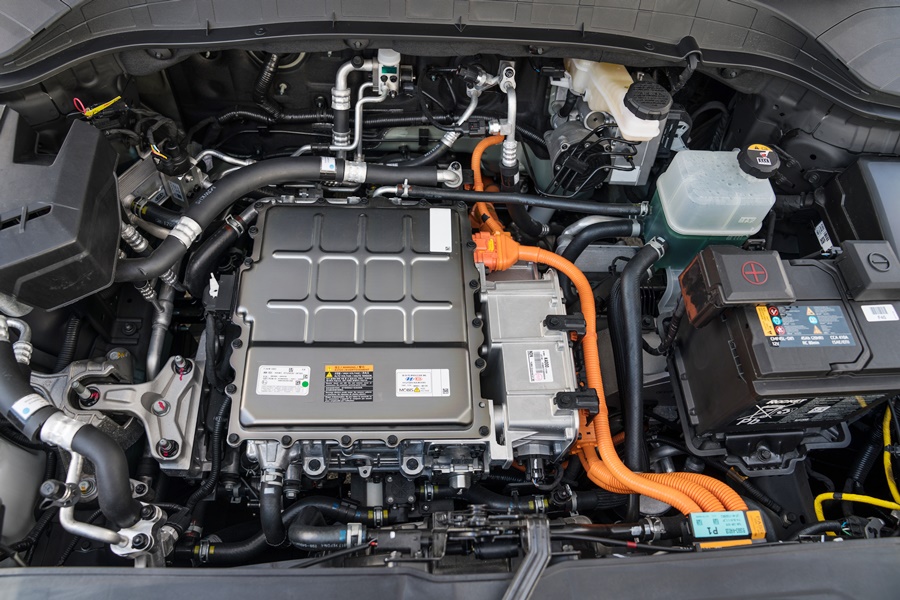

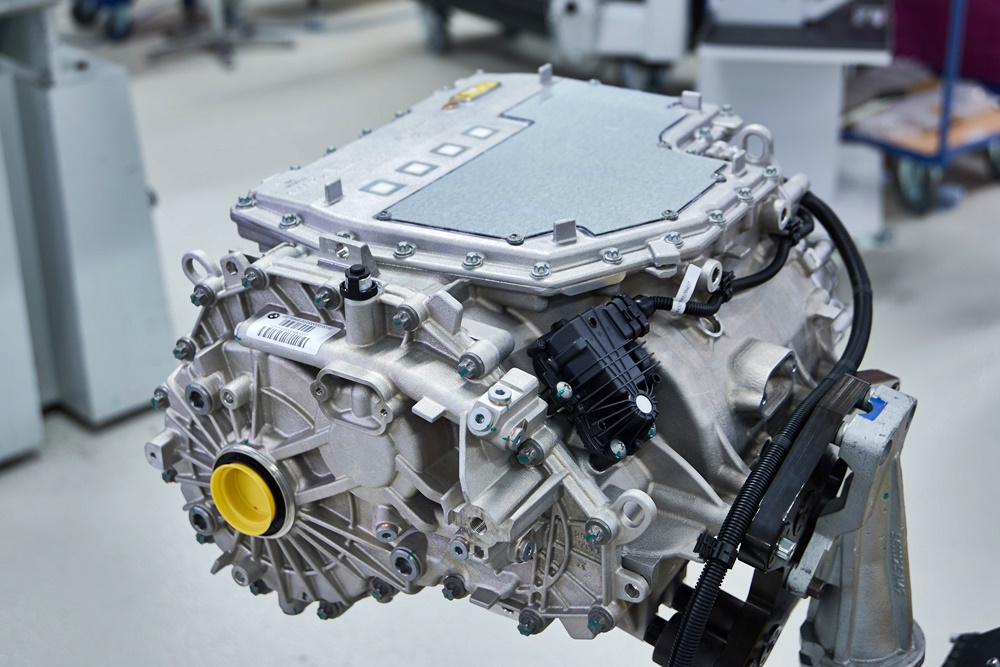

The all-new EV-specific platform (with rear-wheel drive) has been engineered to deliver fun and effortless electric performance (154 ps/315 Nm) with exceptional driving characteristics in urban environments. The claimed acceleration time from 0 to 100 km/h is 8.3 seconds, with a 136 ps variant doing it in 9 seconds.

The 35.5 kWh lithium-ion battery pack provides a claimed range of 222 kms, and 80% of charge can be ‘refuelled’ within 30 minutes in rapid charging mode. Reinforcing the function-led design approach, the car’s advanced charging port is integrated centrally in the bonnet for ease of use from either side of the car. The lid is made of high-strength glass and operated via the key fob or My Honda+ app. LED lighting visible through the sleek cover welcomes the driver upon approach to the car, and communicates by illuminating blue when charging, or red if the charging system detects an error.

In the UK market, the Honda E with the more powerful powertrain will cost £28,660 (about RM152,000) while the lowered powered on will be around 9% cheaper. The prices are after a rebate is given as an incentive for purchases of EVs. The Nissan LEAF, which is the world’s most widely sold EV, costs around £32,500 (RM173,000) even with a rebate but it has a higher-capacity 62-kWh battery pack.

The Honda e is the start of the carmaker’s electrification offensive in Europe. Over the next 36 months, there will be all-new hybrid-only Jazz, a SUV and an additional battery electric vehicle. Honda’s new ‘e: Technology’ branding will unify all its electrified products under the same global name. Ahead of its European 2022 electrification goal, Honda will expand the application of its e:HEV dual-motor hybrid system to the entire line-up of Honda vehicles in Europe, starting with the next-generation Jazz, available from the middle of 2020.

Honda e previews connectivity features you could get tomorrow