With the accelerating move towards electrification by the auto industry, it’s inevitable that high-performance brands will also follow the same trend. While purists will say that electric motors cannot replace powerful internal combustion engines where sheer performance and driving experience are concerned, the companies that are making such cars are going to prove otherwise.

High-performance hybrid

Mercedes-AMG is one of them and its new GT 63 S E PERFORMANCE is a high-performance hybrid that draws on technologies from Formula 1. As a preview of its electrified future, the E PERFORMANCE model uses a combination of 4-litre V8 biturbo combustion petrol engine and a 105 kW electric motor to generate a system output of 843 ps and maximum system torque of more than 1,400 Nm.

This is the most powerful series production model from Mercedes-AMG to date with acceleration from a standstill to 100 km/h claimed to take 2.9 seconds, and 0 to 200 km/h can be reached in less than 10 seconds. From there, acceleration continues strongly right up to 316 km/h.

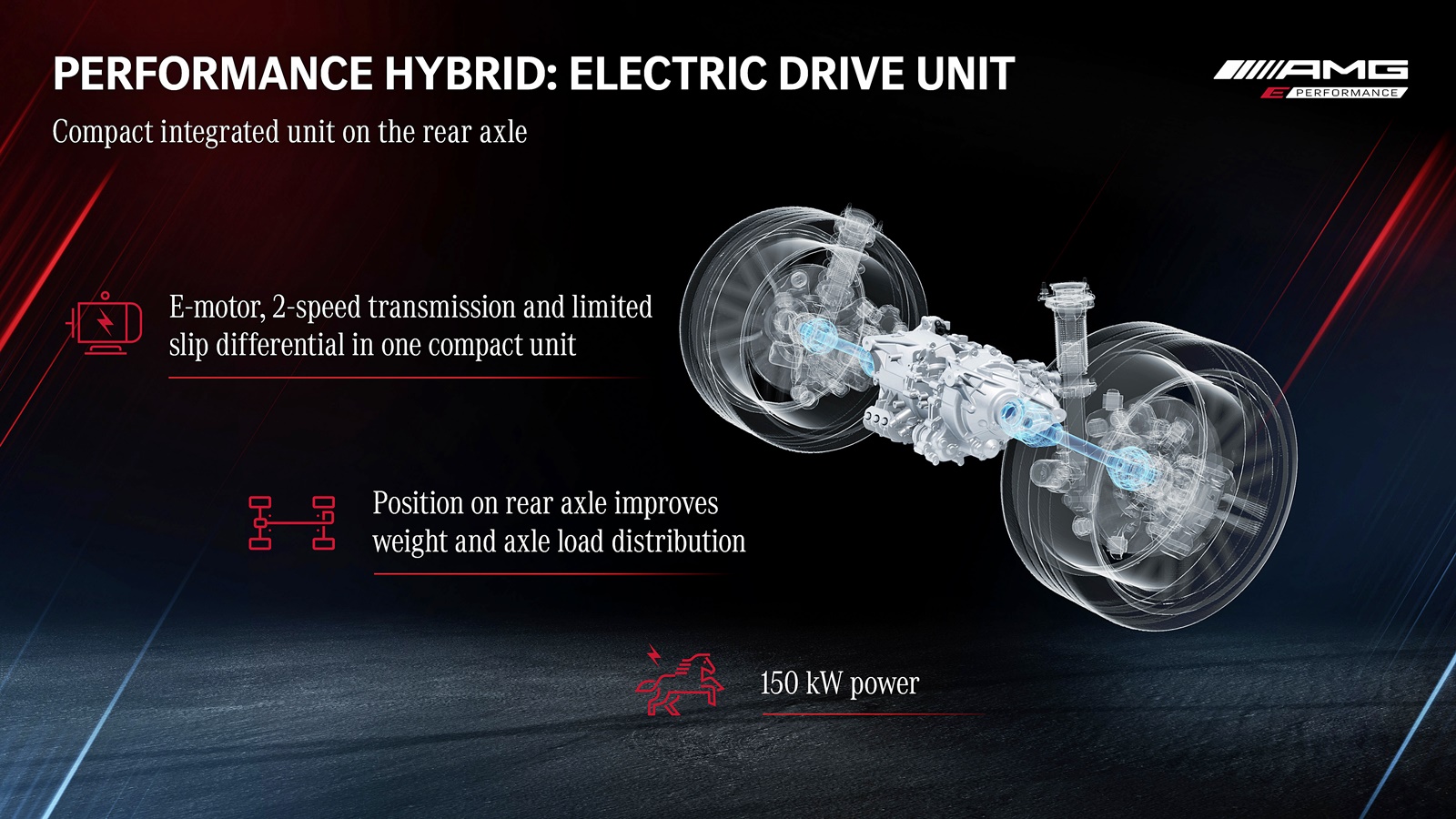

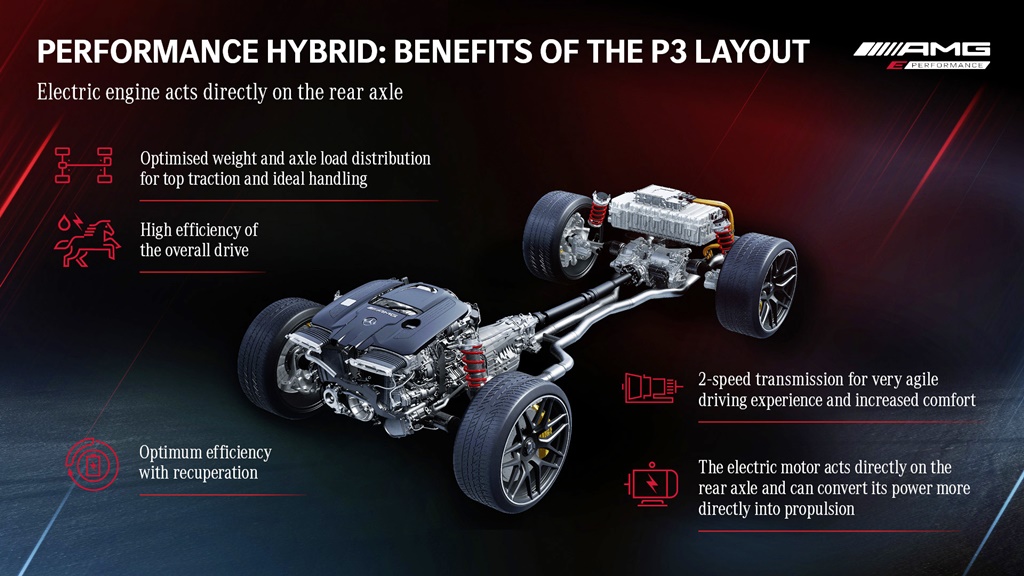

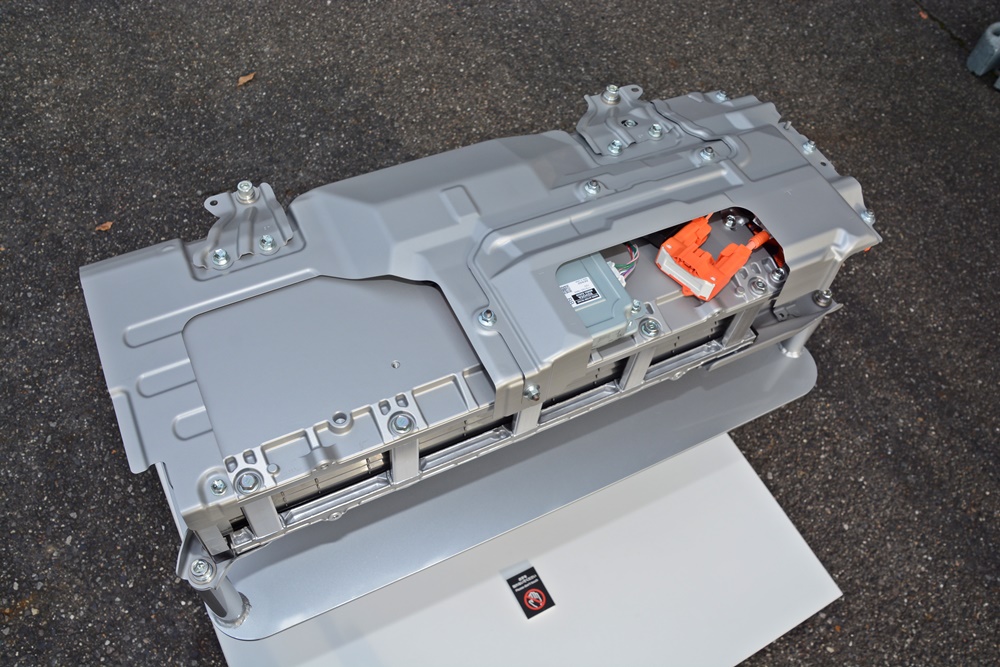

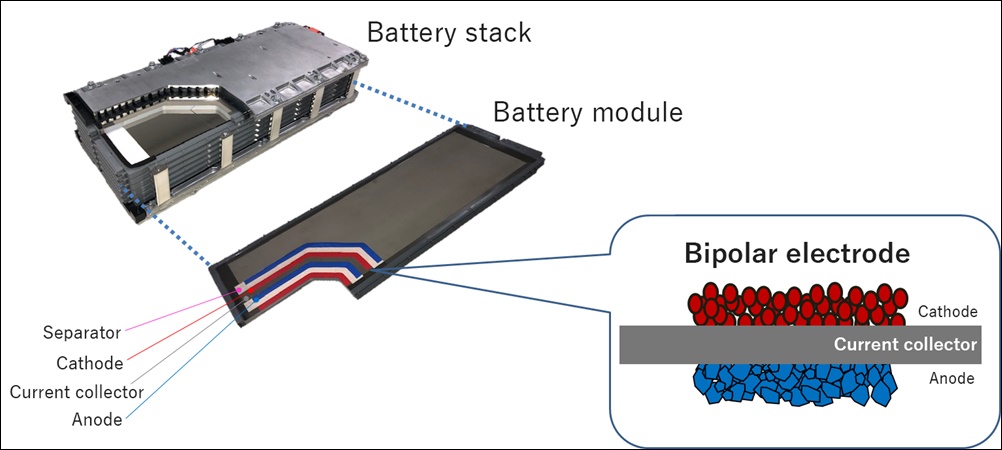

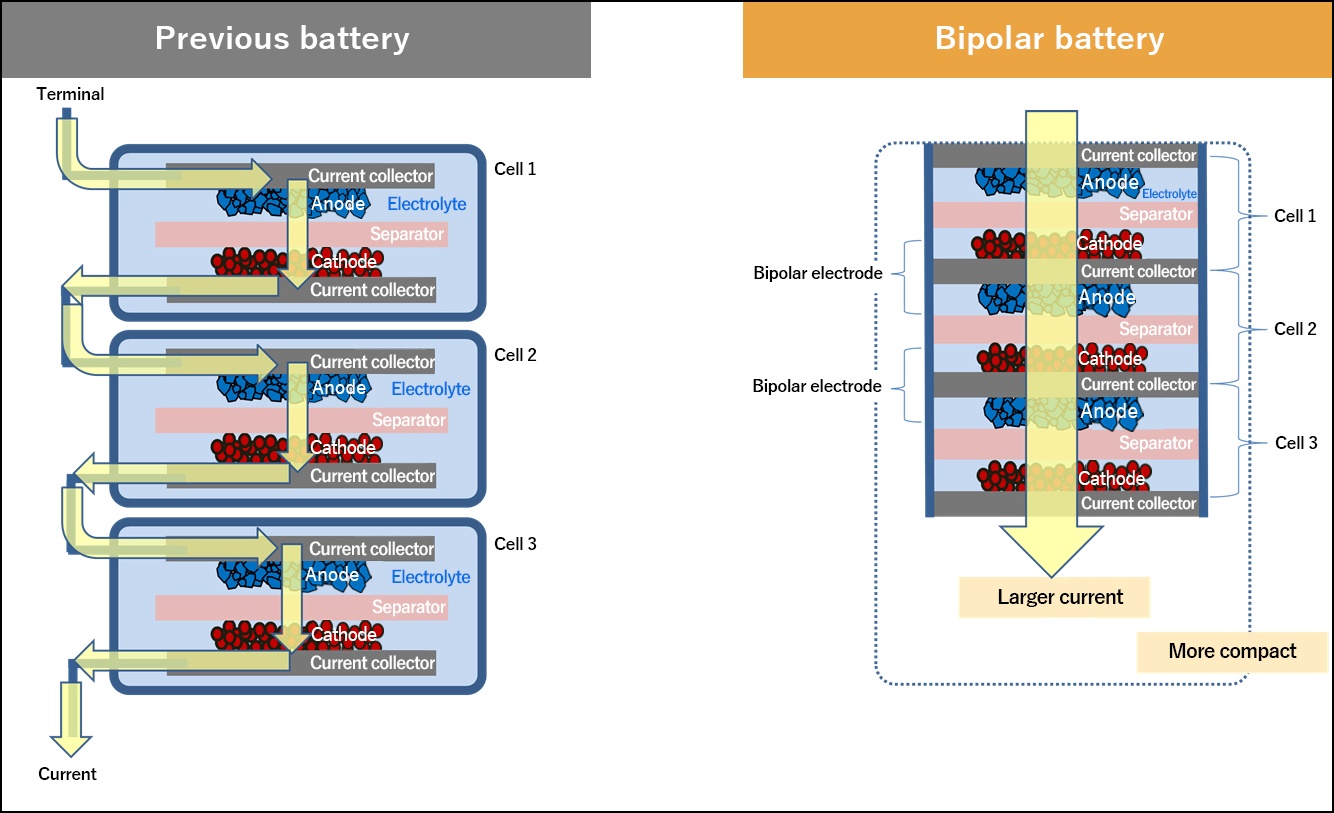

The high-performance 400V battery pack has been developed in-house and, along with the electric motor, is installed on the rear axle. This not only enhances response which is immediate with rapid torque build-up but also improves weight distribution. As with all hybrid vehicles, it is also possible to run on just electricity for a limited range; in the case of the E PERFORMANCE, it is claimed to be 12 kms which would be useful when looking for a parking space or slowly cruising around residential areas with almost no noise.

Electric motor influences vehicle dynamics

The control of vehicle dynamics also benefits from the hybrid drive. Instead of braking intervention by ESP, the electric motor can also control traction as soon as a wheel signals too much slip. To do this, the intelligent control system reduces the drive torque of the electric motor that is transferred to the wheel via the limited-slip rear differential. The result is that ESP does not have to intervene at all, or only later.

This provides a useful advantage in that the combustion engine can be operated with higher torque, which both improves agility afterwards and increases efficiency. In addition, the power otherwise ‘destroyed’ during braking can be used to charge the battery in a regenerative process.

Because the battery pack is always maintained always within the optimum temperature window of around 45 degrees, thanks to direct cooling, regeneration can also be optimised. Regeneration starts when a driver takes his foot off the accelerator pedal, ie in overrun mode without touching the brake pedal. This charges the battery and creates a strong braking torque; the wheel brakes are subjected to less wear or, depending on the regeneration level and traffic situation, do not have to be applied at all.

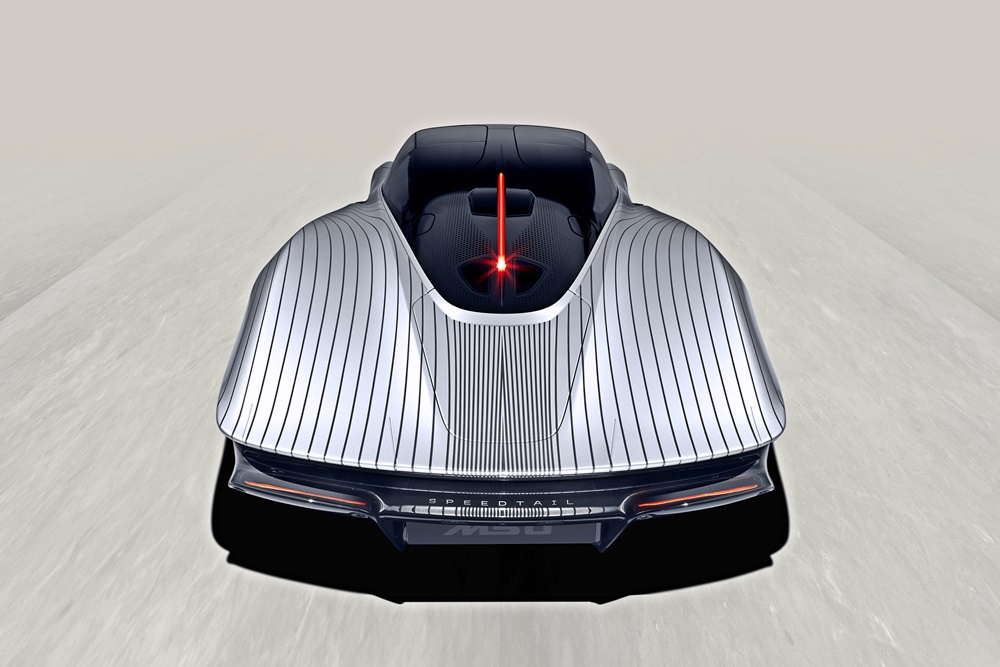

4-door GT coupe styling

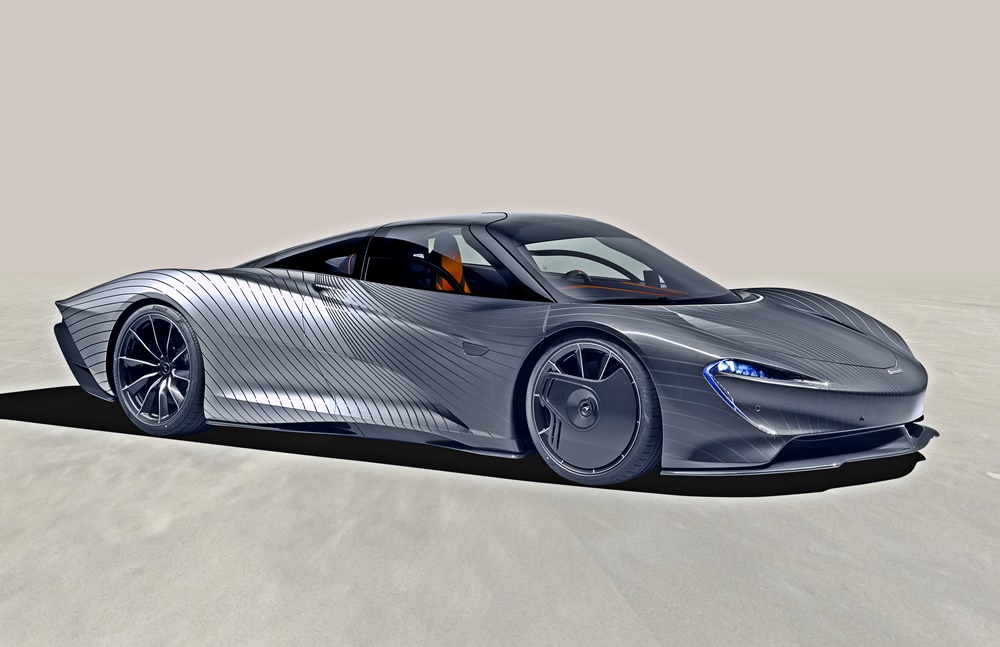

The hybrid model has a similar appearance at the 4-door coupe with the characteristic front apron which is based on the design of the 2-door AMG GT. The outer air intakes are wider and more pointed towards the centre of the car, and the airflow is channelled to the wheel arch coolers by three vertical fins.

Exclusive identification features at the rear are the rear apron with integrated plug-in charging flap and the model designation highlighted in red. With the hybrid, AMG is also introducing externally fluted trapezoidal twin exhaust tailpipes. Customers can personalise their car with the new AMG Night Package II or a combination of the Night Package and Carbon Package.

Flagship of the model series

As the new flagship of the model series, the E PERFORMANCE will be extensively equipped. It has all the upgrades of the latest model facelift, including the AMG RIDE CONTROL+ suspension with a new damping system. Also standard are the adapted AMG ceramic high-performance composite brake system and the latest MBUX multimedia system.

The standard Widescreen Cockpit features the latest MBUX multimedia system with AMG hybrid-specific displays and functions. In the instrument cluster, the driver can read the electric range, the power consumption, the output and torque of the electric motor and the temperatures of the battery and electric motor. High-quality graphics on the multimedia display visualise the power flow of the entire drive system, rpm, output, torque and temperature of the electric motor, as well as the temperature of the battery. The rear-seat passengers can also view information on the energy flow as well as the power and torque of the electric motor on their optional multimedia display.

The standard AMG Performance steering wheel with its distinctive twin-spoke design and integrated control buttons is fitted. The three rounded twin spokes combine strength with lightness, while the buttons have brilliant displays and an efficient turn-and-press operating logic. This allows important driving functions and all driving modes to be controlled without having to take one’s hands off the steering wheel. As a new feature, it is possible to select the regeneration levels of the hybrid drive via the steering wheel buttons.

AMG sound

When driving on all-electric power, the legally required Acoustic Vehicle Alerting System warns the surroundings that the car is approaching. A specially composed low-frequency, speed-dependent AMG sound is emitted to the outside via single loudspeakers at the front and rear. The sound can also be heard at a subdued level in the interior, as acoustic feedback for the passengers.

At higher speeds, the customer can select the sound experience between ‘balanced’ and ‘powerful’ using the sound buttons in the centre console or on the steering wheel. When the combustion engine starts, the selected setting influences the sound of the exhaust system. In every situation, one thing remains the same: under all conditions, the E PERFORMANCE will be immediately recognisable as an AMG by its sound.

“With the new Mercedes-AMG GT 63 S E PERFORMANCE, we are transporting our brand DNA into an electrified future. In doing so, we are following our own technical path, which is what has always made AMG so special and desirable. Developed entirely in Affalterbach, the performance hybrid offers a fascinating level of driving dynamics and rightly bears our new technology label E PERFORMANCE. With this new concept, we are also opening up to new target groups who will experience Mercedes-AMG as the performance luxury brand of the 21st century,” said Philipp Schiemer, Chairman of the Board of Management of Mercedes-AMG GmbH.

Brand ambassador is will.i.am

Mercedes-AMG is breaking new ground in communication on electrification together with brand ambassador will.i.am. The well-known musician and multiple Grammy Award winner from the Black Eyed Peas contributed to the marketing campaign concept and wrote an exclusive song for the release video.