Although the Nissan Kicks, inspired by the streets of Brazil, has been around since 2016, it has not been available in ASEAN. To make up for that, the carmaker has launched the e-POWER version and it’s actually a world debut which took place in Thailand. The model is built at the Nissan factory in the country as well.

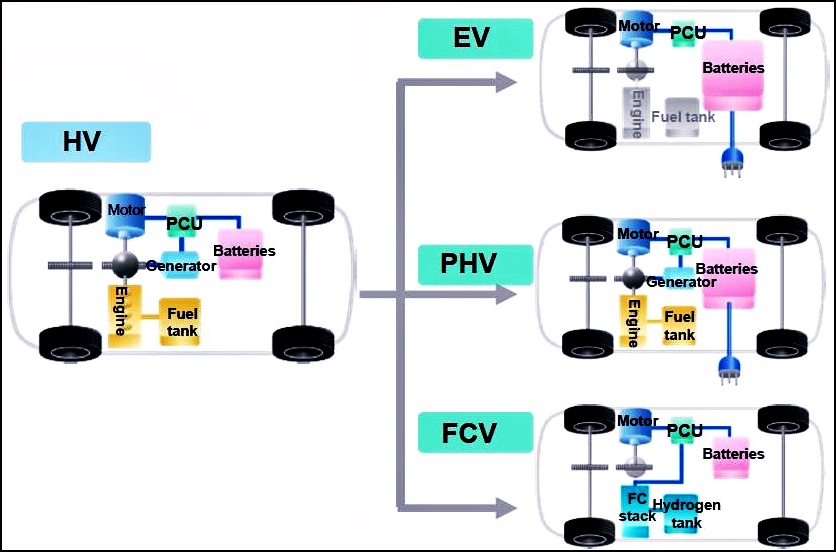

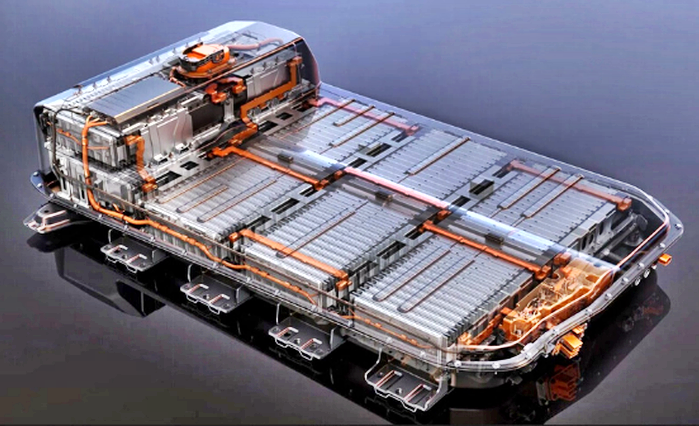

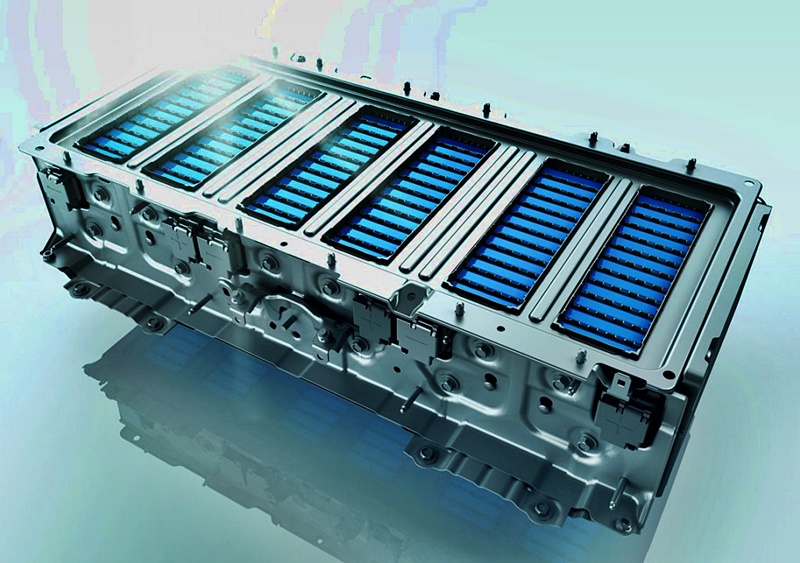

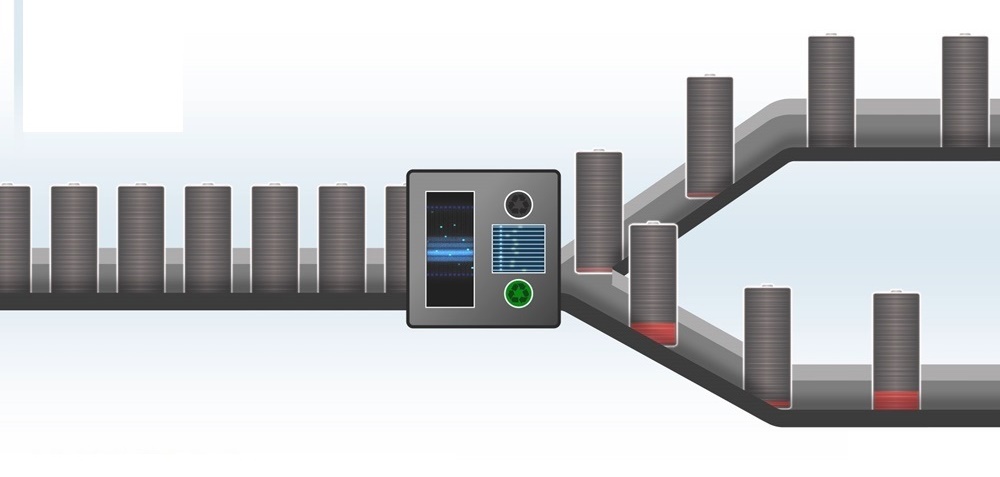

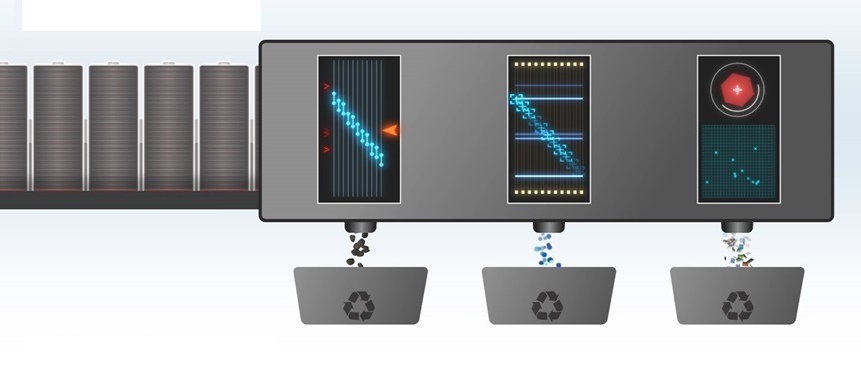

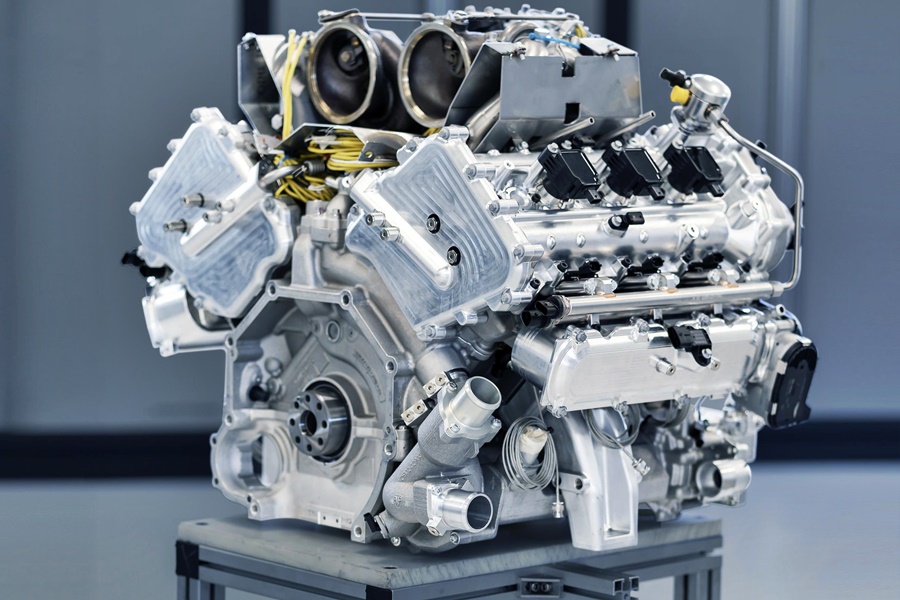

The Kicks e-POWER, as the ‘e’ suggests, uses an electrified powertrain. The technology used in e-POWER has been proven in Japan where it has been available for the past few years. The compact hybrid powertrain uses an EM57 electric motor, generator and inverter that generates electricity from its 1.2 litre DOHC 12-valve 3-cylinder petrol engine. Electricity is stored in a 1.57 kWh lithium-ion battery pack

The e-POWER system can generate a maximum power output of 95 kW/129 ps, with up to 250 Nm of torque. Unique to e-POWER technology, when extra acceleration is required or when climbing a steep hill, the electric motor receives power from both the battery and the engine to enhance its performance. During deceleration, the engine stops running, and regenerative power is used to charge the battery until the vehicle comes to a complete stop, wasting no energy generated from deceleration.

The driving experience is also enhanced by intelligent accelerator technology. Its one-pedal technology (also found in the latest LEAF EV) allows drivers to launch, accelerate, decelerate, or stop the car by using only the accelerator pedal. By using only one pedal, tasks such as judging the distance between cars, decelerating, and stopping when going downhill or stopping for traffic lights are greatly simplified.

The driver can choose from 4 driving modes: Normal, S, Eco and EV. In Normal, the car produces strong acceleration off the line and stopping power (lifting off the acceleration pedal) that is claimed to be on par with the braking of its conventional petrol-powered counterparts. In S, the car accelerates quicker with enhanced stopping power. Eco is the fuel-saving mode which is regulated by battery power. EV mode uses stored battery electric power only, allowing a quiet drive experience without the petrol engine operating.

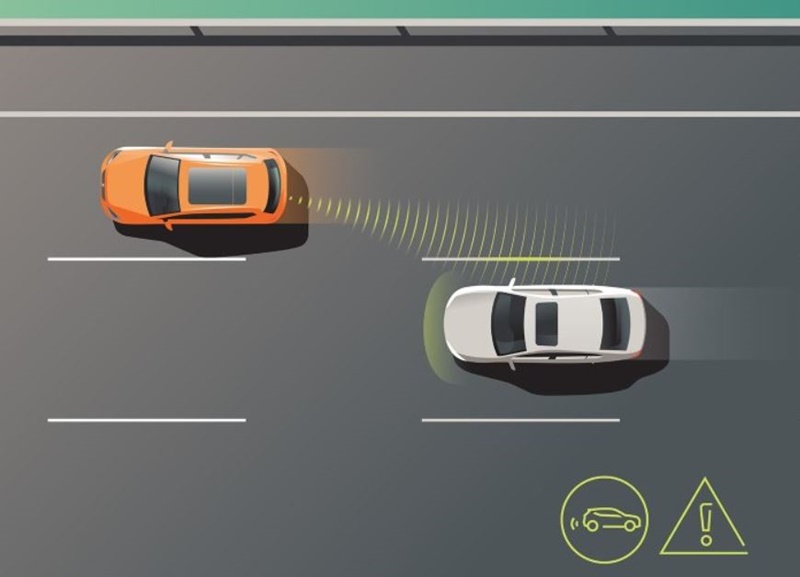

The Kick features 14 best-in-class Nissan Intelligent Mobility technologies. These include Intelligent Cruise Control, Intelligent Forward Collision Warning, Intelligent Emergency Braking, Blind Spot Warning, Rear Cross Traffic Alert, Intelligent Around View Monitor with Moving Object Detection and Intelligent Rear View Mirror.

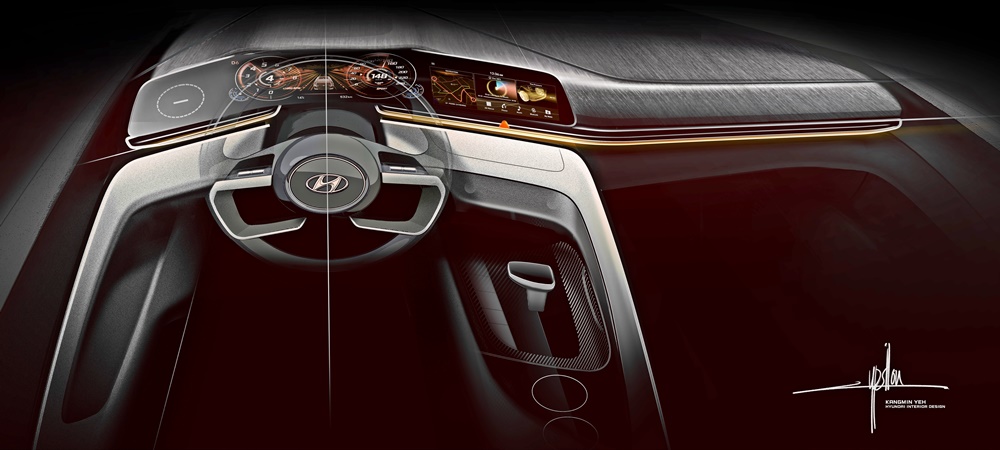

Inside the Kicks

Inside, the passenger cabin features high-quality design and refinement, including the modern and simple ‘Gliding Wing’ instrument panel design that is dominated by a centrally-mounted 7-inch full-colour display housing a comprehensive infotainment system.

Intelligent Integration elements are powered by Nissan Connect, a multi-infotainment system with 8-inch touchscreen Colour Display Audio. It keeps customers ahead of the curve by bringing infotainment, navigation, safety and security under a single platform with a seamless connection via smartphone (Apple CarPlay for iOS).

“The launch of the all-new Nissan Kicks e-POWER in Thailand represents the disruptive and innovative DNA of Nissan that we continue to bring to the region,” said Yutaka Sanada, MC Chairman and Regional Senior Vice-President, Nissan Asia & Oceania. “This is an exciting day for Nissan and Thailand, as a key global production and export hub for Nissan and regional leader driving the company’s vision for electrification of mobility.”

In Thailand, the price range for the four versions start from 889,000 baht and goes up to 1,049,000 baht (RM120,650 – RM142,360). The battery pack is designed to last for up to 10 years and the electric system for up to 5 years. This is complemented by a factory warranty of 3 years or maximum of 100,000 kms.

Coming to Malaysia?

Last year, Edaran Tan Chong Motor (ETCM) did some promotion of EVs and also launched the second-generation LEAF EV as well as the X-Trail Hybrid. With the Almera already long in the market, it would seem like a good idea to replace it with the Kicks. However, whether the e-POWER variant will be offered or just with a conventional powertrain remains to be seen. Typically, ETCM is tight-lipped about new models although it has mentioned that this new model will be offered in future.

Visit www.nissan.com.my to know more about the LEAF and X-Trail Hybrid.