Brake Assist (BA) is a feature which is listed among the active safety systems of many cars today but how it works and why it enhances stopping may not be known by most motorists. BA, which appeared in the second half of the 1990s, is a supplementary brake system which can also be considered a driver assistance system.

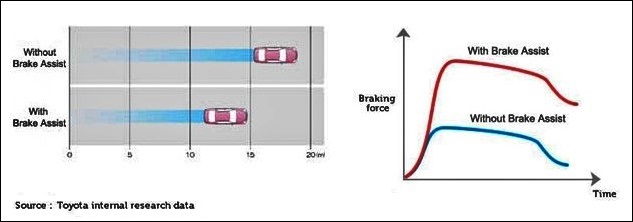

A simple explanation of BA would be that it boosts braking pressure to the maximum available as this can have a positive effect on the stopping distance, especially with anti-lock braking systems, better known as ABS.

Helping older people brake better

When Toyota first introduced it in 1997 in the Raum model, it said that one of the reasons for developing BA was to help older drivers. These drivers might not apply full pressure on the brake pedal in an emergency, or may not have sufficient strength. Thus, the system will detect when there is emergency braking, eg sudden pressure on the pedal, and boost the pressure to maximum.

Emergency braking can save lives. However, many drivers then step on the brake pedal quickly but not forcefully enough – this is what Mercedes-Benz engineers discovered in the early 1990s during tests in the company’s own driving simulator. Their answer was BAS, considered one of the key links in the chain of important Mercedes-Benz safety developments.

BAS evolved from ESP

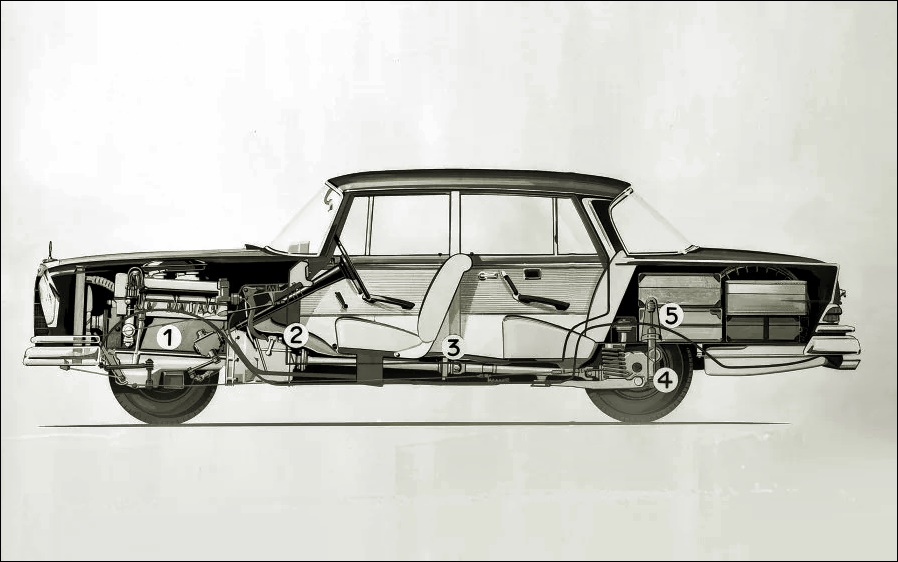

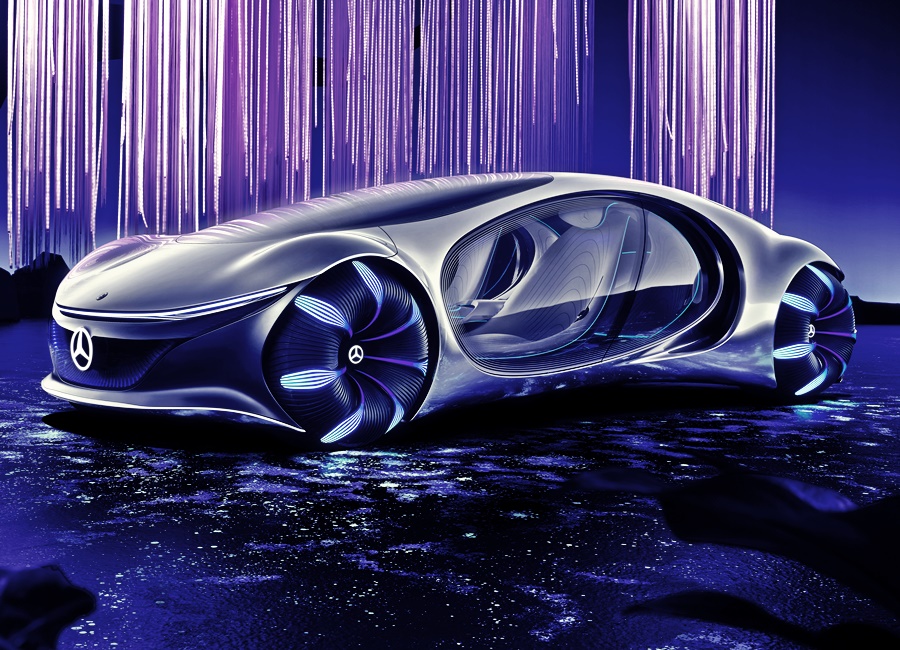

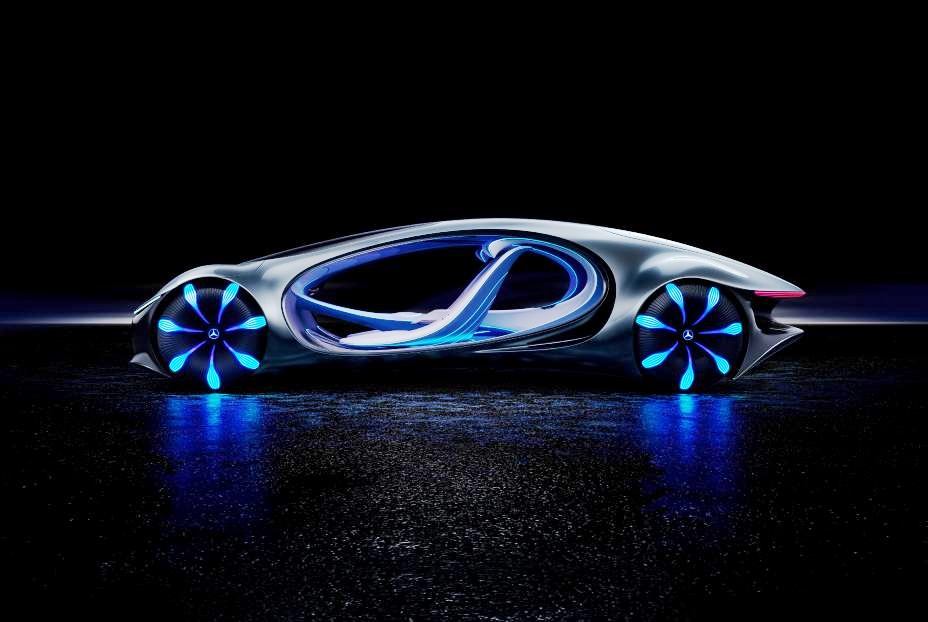

Mercedes-Benz introduced their version of Brake Assist, which they referred to as BAS, in late 1996. It was standard initially in the S-Class (W 140) and SL (R 129) and built upon the functions of the Electronic Stability Program (ESP), or vehicle stability control as it is also known.

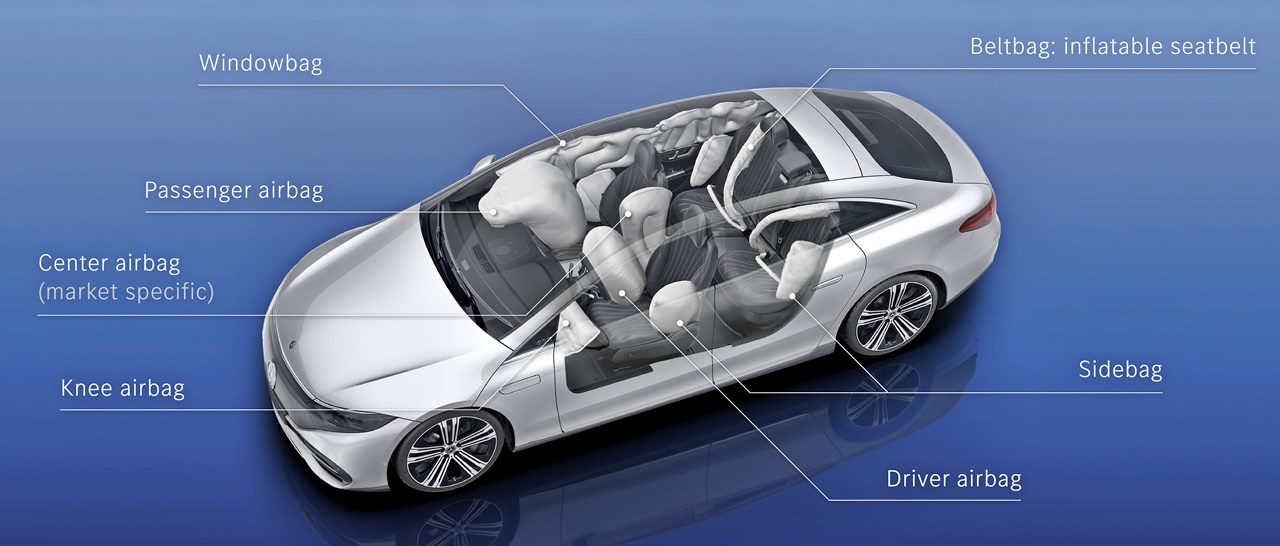

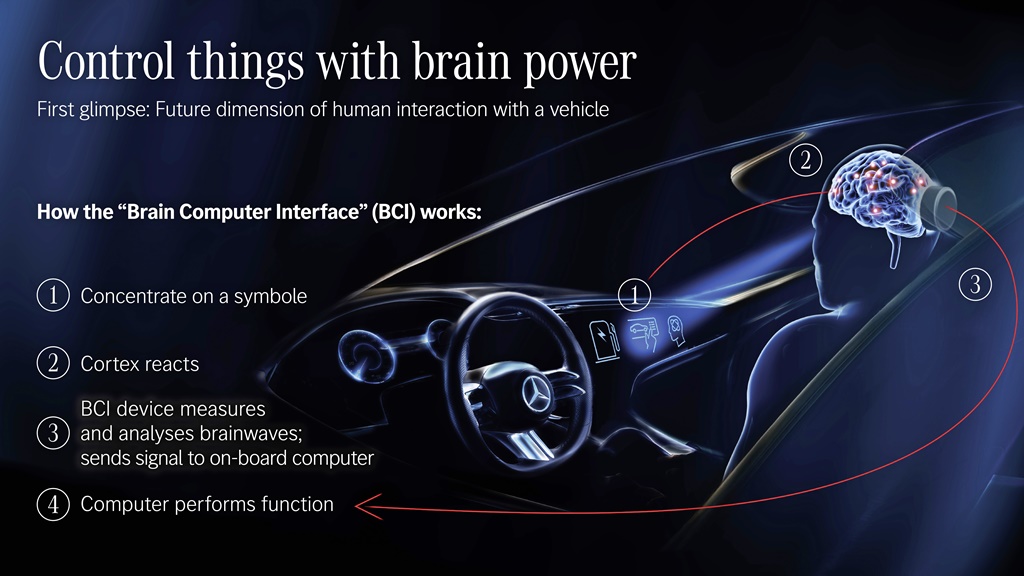

These advanced systems not only use the sensors installed in the car but also state-of-the-art radar technology in order to capture the scene in front of the car and to identify a situation in which an accident is imminent. Mercedes-Benz offers very similar systems for its commercial vehicles known as Active Brake Assist (in the Actros heavy-duty truck).

How well does BAS work?

BAS interprets a certain speed at which the brake pedal is depressed as an emergency situation and builds up maximum brake boost within fractions of a second. This significantly shortens the braking distance – at 100 km/h on dry roads, for example, by up to 45%. Mercedes-Benz investigated its effect in the driving simulator and found that BA was able to mitigate or even prevent rear-end collisions.

It also made an effective contribution to pedestrian protection. In a series of experiments, 55 car drivers drove through a town at 50 km/h when suddenly a child ran onto the carriageway. Only full braking prevented the accident.

Additional functions with BAS PLUS

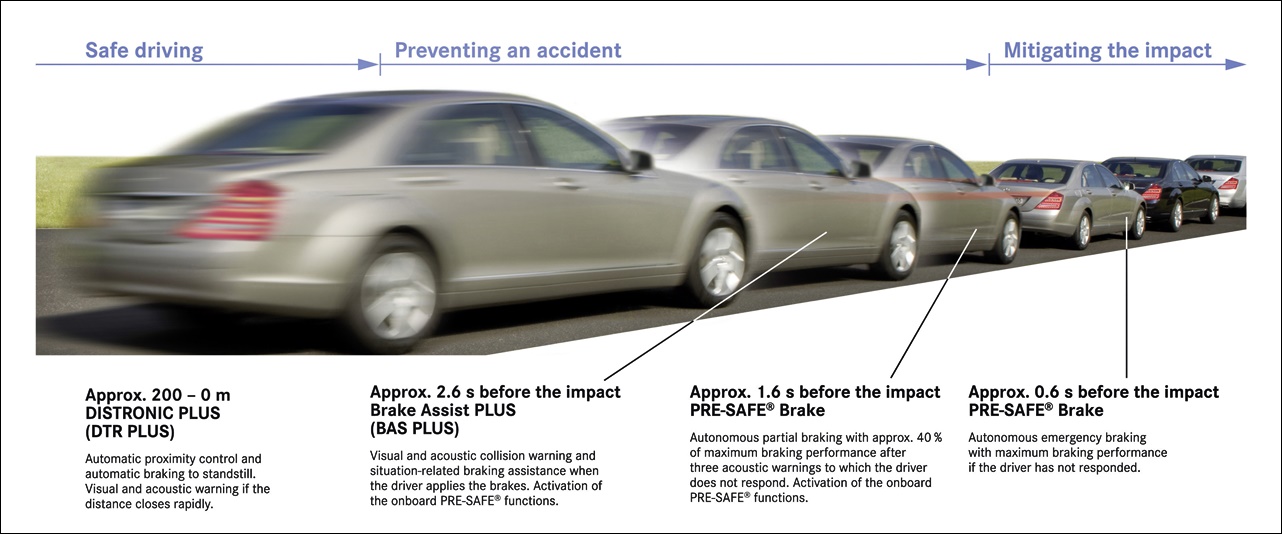

The next evolutionary stage by the German carmaker was Brake Assist PLUS which made its debut in the S-Class from the W 221 series in late 2005. Besides warning the driver of an imminent head-to-tail crash by means of visual and acoustic signals, it automatically computes the brake pressure required to prevent the accident.

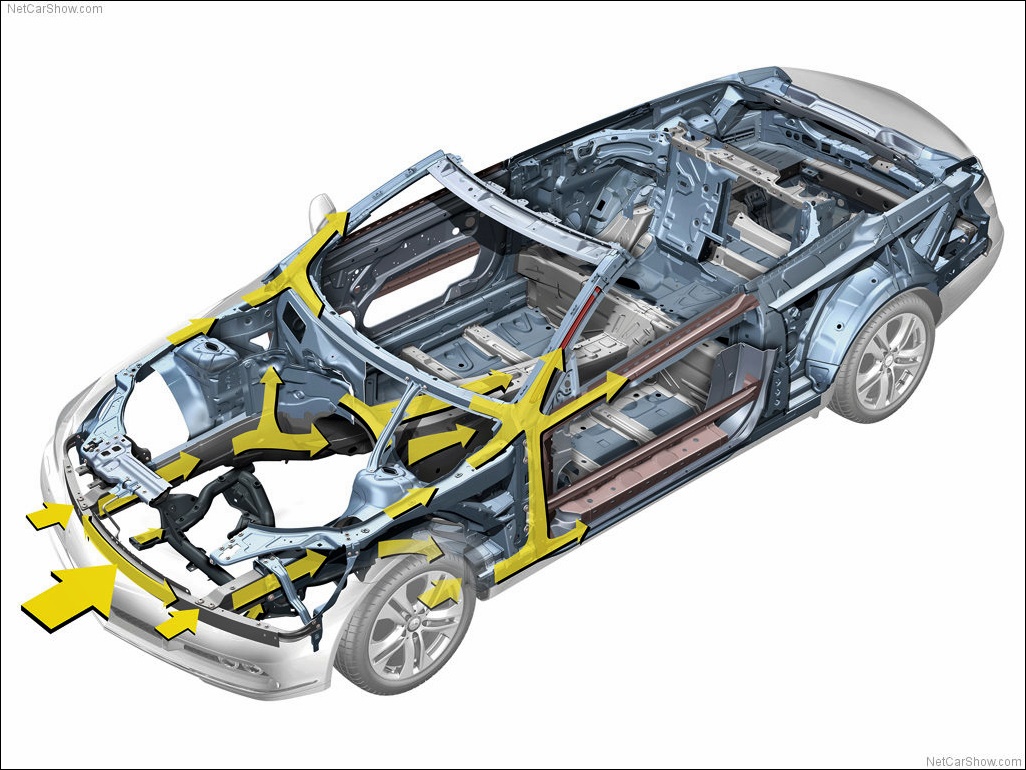

BAS and BAS Plus are integrated in the PRE-SAFE brake system that is today available in every Mercedes-Benz car. PRE-SAFE can automatically brake the car if a collision is predicted, and the PRE-SAFE brake works together with the BAS PLUS, the latter making its brake boosting effect available as soon as the driver steps on the brake pedal. If the driver does not react to the warning signals emitted by BAS PLUS, the PRE-SAFE brake initiates automatic partial braking to decelerate the car with some 40% of the maximum brake power.

Radar technology made the advanced capability of BAS PLUS possible. It detected the distance to cars ahead, warned the driver of insufficient distance and calculated the necessary braking assistance in the event of an imminent collision. If traffic came to a standstill and the driver actually had to step on the brake pedal, BAS PLUS built up the brake pressure calculated for the respective situation instantly.

BAS PLUS uses two radar systems: a 24-gigahertz short-range radar scanning the surroundings in front of the vehicle with an aperture angle of 80 degrees and a range of 30 metres. In addition, the 77-gigahertz radar of DISTRONIC scans 3 lanes of a motorway up to a distance of 150 metres with an aperture angle of 9 degrees. Tested in the driving simulator, the results were impressive: while the accident rate in tests with conventional braking technology was 44% on average, it dropped by three quarters with the help of BA PLUS.

Braking systems remain essential for road safety. In addition, emergency braking systems triggered on the basis of detecting potential accidents are an important foundation for the highly automated vehicles to come, and thus an essential part of the vision of accident-free driving.

Data for Road Safety initiative in Europe provides advance warning of dangers ahead