Even before the excitement with the all-new Honda City Hatchback has died down, Honda Malaysia is preparing to launch another all-new model – the 11th generation of the Civic. It will be launched in the first quarter of 2022, and those who want to be the first to own one can place a booking now at any authorized Honda dealer nationwide. Prices and variants have not been revealed (although we know there will be an RS variant for the first time), but sales tax will not be charged till after June 30, 2022.

Evolutionary styling changes

The new Civic has undergone an evolutionary styling change that gives it a ‘New Age Identity’. The focus on the new exterior design is to give the driver and occupants a more expansive view from within, enhancing the feeling of spaciousness. This has been achieved by expanding the glass area with windscreen pillars repositioned further back.

The Civic RS, flagship of the new range, will come with black finishing for the housings of the door mirrors, Shark Fin antenna, Outer Door Handles, boot spoiler and also the 18-inch alloy wheels. The new lighting units use LEDs and have new designs while the Civic’s styling DNA is reflected in the rear lights.

Longer and wider body

Measuring 4678 mm in length, 1802 mm in width, with a height of 1415 mm and a wheelbase of 2735 mm, the new Civic is larger and wider with the rear track also widened to provide a low and wide stance. The factory in Melaka will use Honda’s advanced manufacturing technique employing Lazer Brazing technology (a Civic-first) which gives a sleeker roofline and strengthens body rigidity.

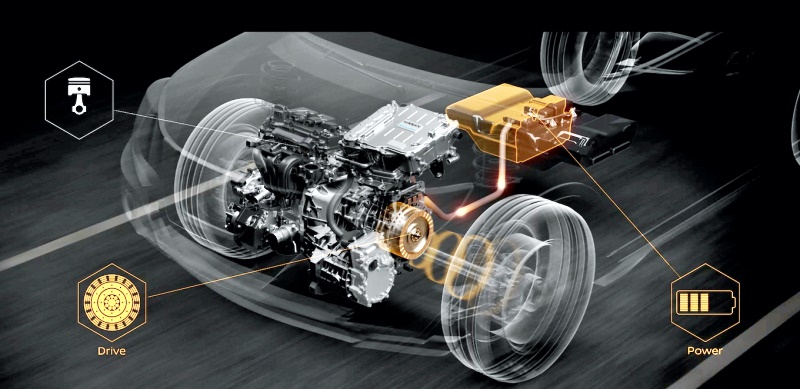

The familiar and proven VTEC 1.5-litre turbocharged 4-cylinder engine will be used again. The latest version generates higher power output which is a maximum of 182 ps, with 240 Nm of torque. That’s even more powerful than the 2.4-litre engine that powered the Accord.

5 stars from ASEAN NCAP

ASEAN NCAP has already tested the new Civic and it received a maximum overall score of 5 stars. It is the first Honda model to be assessed under the new ASEAN NCAP 2021-2025 protocol which includes requirements for protecting motorcyclists.

Honda SENSING will be offered with the Civic RS and the driver assistance package is said to have improved functionality by offering natural and smooth steering operation. The Honda SENSING suite has 9 active safety systems which can help the driver avoid an accident or reduce the effects of one. A new addition is Lead Car Departure Notification System which alerts the driver when the vehicle ahead moves off. There is also a Driver Attention Monitor which will reduce the dangers of a fatigued driver losing attention by alerting the driver if unusual driving behaviour is noticed.

A segment leader

“The Civic has a strong identity and is one of the favourite Honda models for Malaysians who love a car with exceptional styling and powerful performance. Since 2001, we have sold close to 148,000 units of Civic and this legendary model continues to expand its fan base in the country. The iconic 10th Generation Civic, which was launched in 2016, has contributed more than 66,600 units to the total Civic sales and continues to lead in the C-segment with 71% market share as of October 2021,” said Honda Malaysia’s Managing Director and CEO, Madoka Chujo.

“The 11th Generation Civic, which is a modern interpretation of the classic, offers a piece of the future. It raises the benchmark of a C-segment sedan in every way while maintaining the best of the Civic DNA which is loved by Malaysians. The All-New Civic is truly A Legacy, Reborn!” she added.

To locate an authorised Honda dealership for more information or to make a booking, visit www.honda.com.my.

New Honda Civic gets top safety rating from ASEAN NCAP (w/VIDEO)