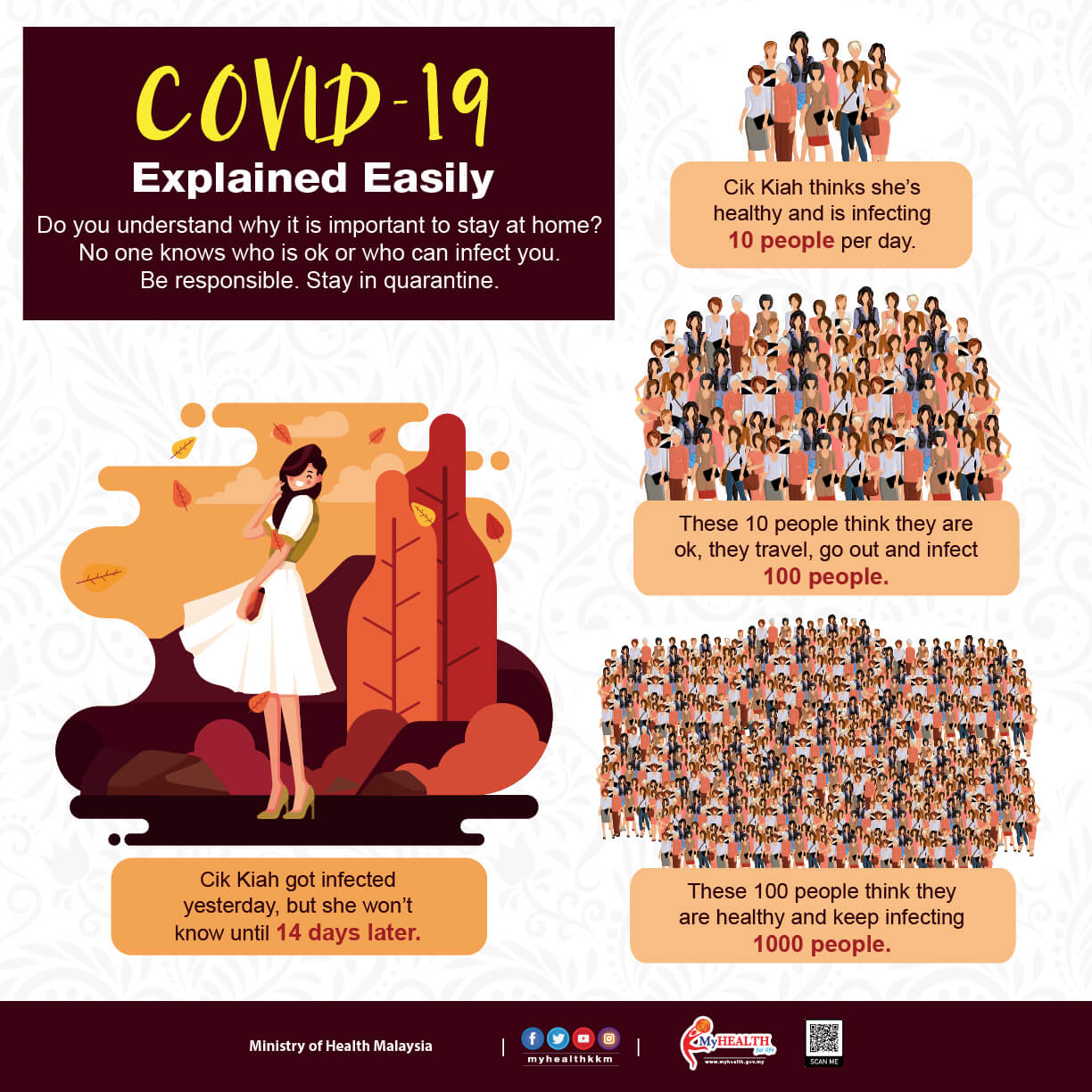

With a year still to go before its market launch at the end of 2021, the BMW Group is providing a first look ahead to the future BMW iX, the production reality of the BMW Vision iNEXT. Currently undergoing extensive development work, the iX is the first model based on a new, modular, scalable future toolkit developed by the Group.

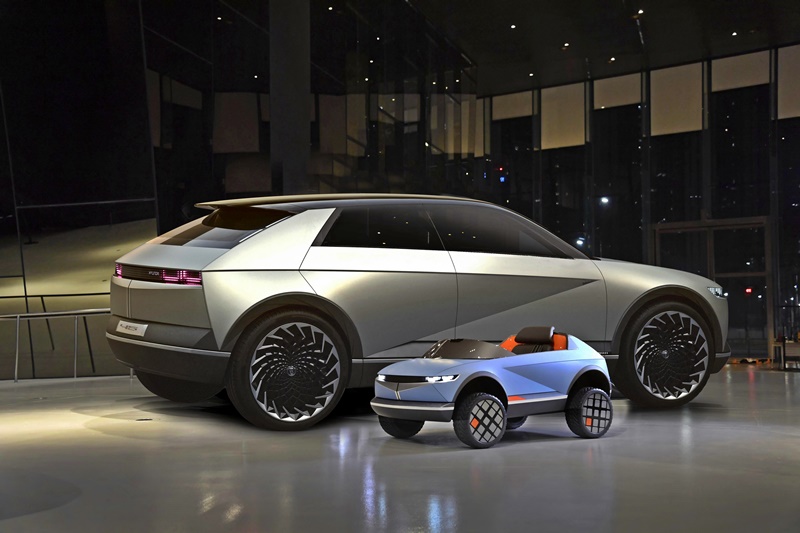

Conceived from the outset for purely electric mobility, the iX sees BMW redefining the Sports Activity Vehicle (SAV) concept that it introduced in the late 1990s with the X5. Just as the X5 was a pioneering model for the carmaker, so too is the iX which is the first representative of what the company promises to be ‘a trailblazing generation of cars’.

The iX harnesses the latest innovations in the fields of electrification, automated driving and connectivity to deliver a mobility experience with people at its core. To this end, its design has been developed from the inside out to provide quality of life and wellbeing for drivers and passengers.

BMW Group’s new technology flagship

The design and technology of the iX form an overall package that lays the foundations for what is in many respects a new kind of driving experience. In so doing, it comprehensively embodies the character of the BMW i brand, whose mission is to transform personal mobility. BMW i plays a central role at the BMW Group as a ‘workshop for the future’ and driver of innovation across the company.

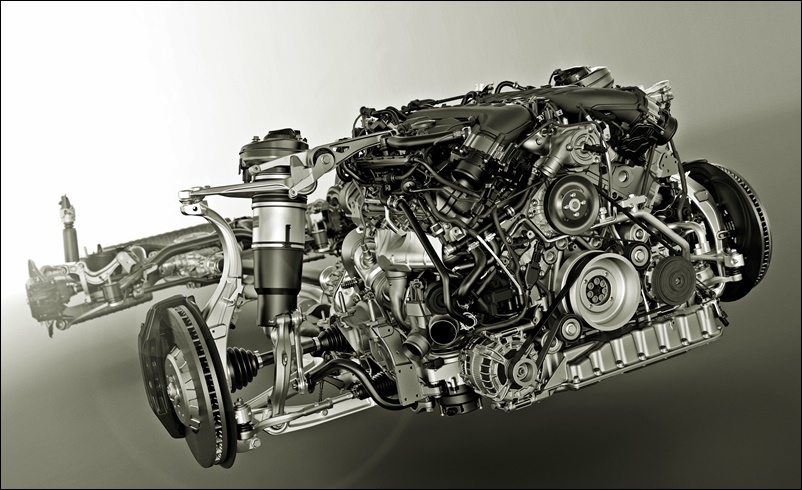

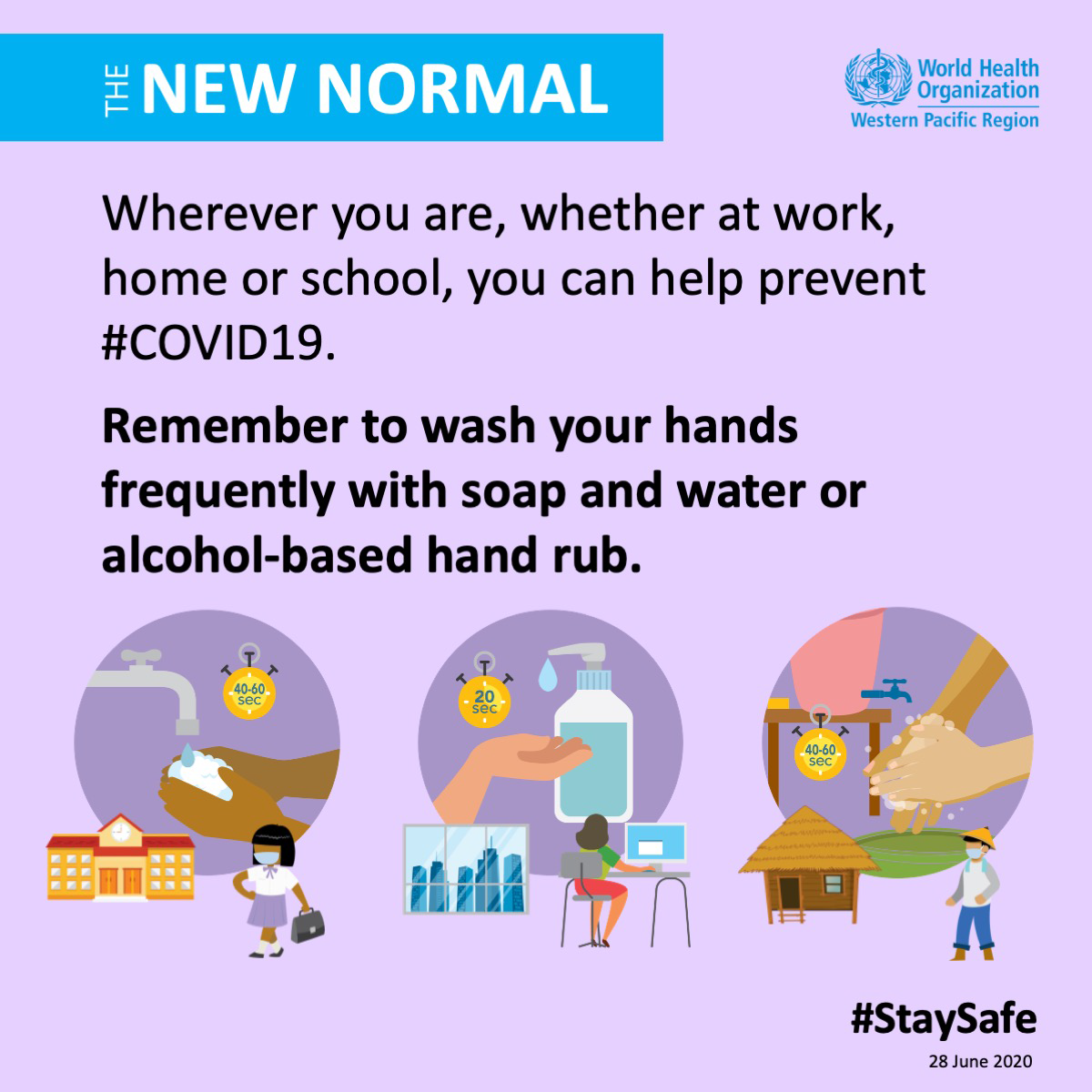

Testing the BMW eDrive systemThe iX will go into production at BMW Plant Dingolfing from the second half of 2021 as the BMW Group’s new technology flagship. It brings together the company’s latest developments in the strategic innovation fields of Design, Automated Driving, Connectivity, Electrification and Services. Added to which, the vehicle concept and design of the iX are rooted in an all-embracing approach to sustainability. This is reflected in areas of the car such as its optimised aerodynamics, intelligent lightweight design and extensive use of natural and recycled materials

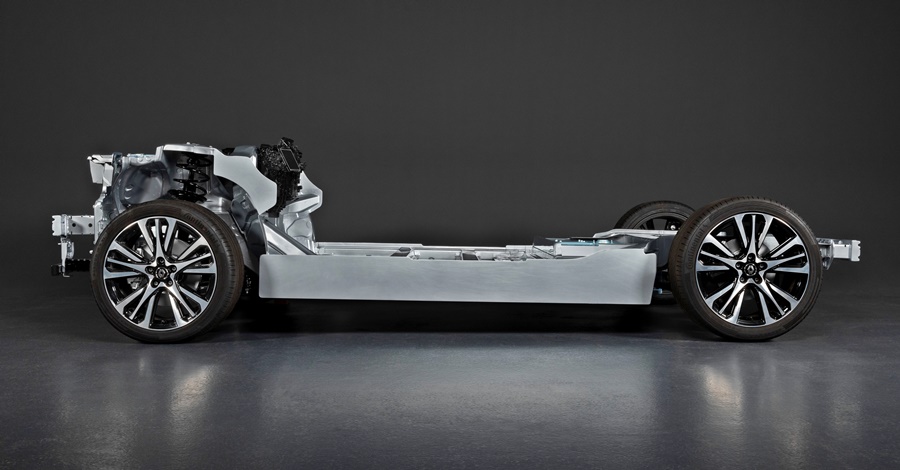

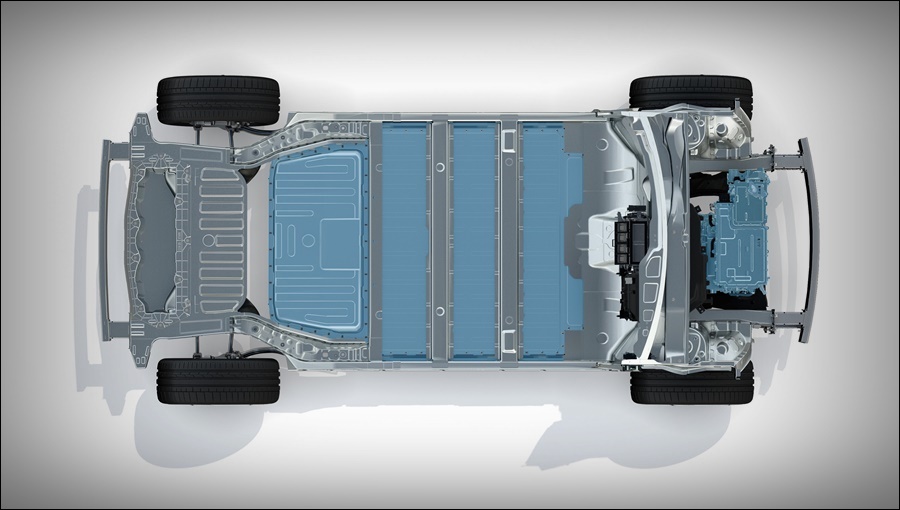

Fifth-generation BMW eDrive technology

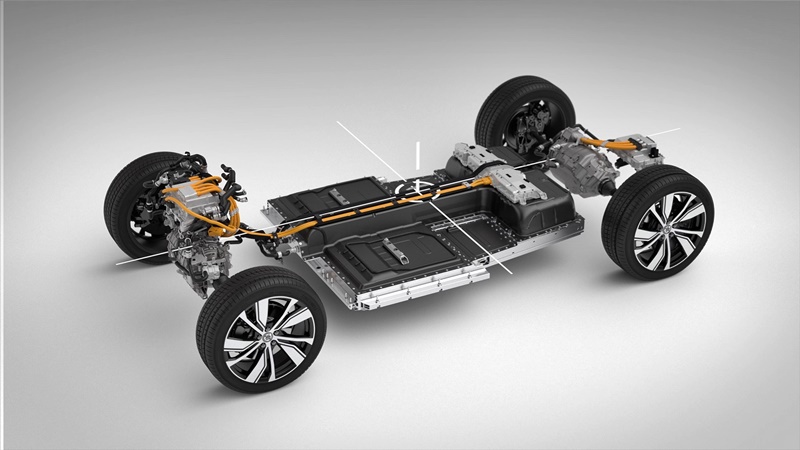

The iX will adopt the BMW eDrive technology and the fact that this technology is in the fifth generation shows how far the BMW Group has come in the field. The eDrive comprises two electric motors, the power electronics, the charging technology and the high-voltage battery – and guarantees exceptional operating and running efficiency.

The power unit developed by the BMW Group has been manufactured sustainably without the use of critical raw materials known as rare earths and will, by the most recent calculations, develop maximum output of more than 370 kW – equivalent to 500 hp. That will power the iX from 0 to 100 km/h in less than 5.0 seconds, it is claimed.

At the same time, the vehicle’s clear aim is to post an exceptionally low combined electric power consumption figure for its segment of less than 21 kWh per 100 kilometres in the WLTP test cycle. A gross energy content of more than 100 kWh should enable the latest-generation high-voltage battery to record a range of over 600 kms in the WLTP cycle. That equates to more than 480 kms according to the US EPA’s FTP-75 test procedure.

10 minutes for over 120 kms range

The new charging technology of the iX enables DC fast charging at up to 200 kW. In this way, the battery can be charged from 10% – 80% of its full capacity in under 40 minutes. For those who are in a hurry and cannot spend too much time on recharging, 10 minutes of recharging will provide a range of over 120 kms (this of course depends on driving conditions). It is projected to take less than 11 hours to charge the high-voltage battery from 0 to 100% at 11 kW from a Wallbox.

The battery pack fitted in the iX is designed as part of a long-term resource cycle and enable an exceptionally high recycling rate. The power used to produce the battery cells for the battery pack as a whole come exclusively from renewable sources.

New technology toolkit

The new technology toolkit making its debut in the iX also provides the platform for significant progress in the areas of automated driving and digital services. For example, the level of computing power has been developed to process 20 times the data volume of previous models. As a result, around double the amount of data from vehicle sensors can be processed than was previously possible.

“We are setting new industry standards with the technology in the BMW iX. The iX has more computing power for data processing and more powerful sensor technology than the newest vehicles in our current line-up. 5G-capable, it will be given new and improved automated driving and parking functions and uses the high-performing fifth generation of our electric drive system,” said Frank Weber, Member of the Board of Management of BMW AG, Development.

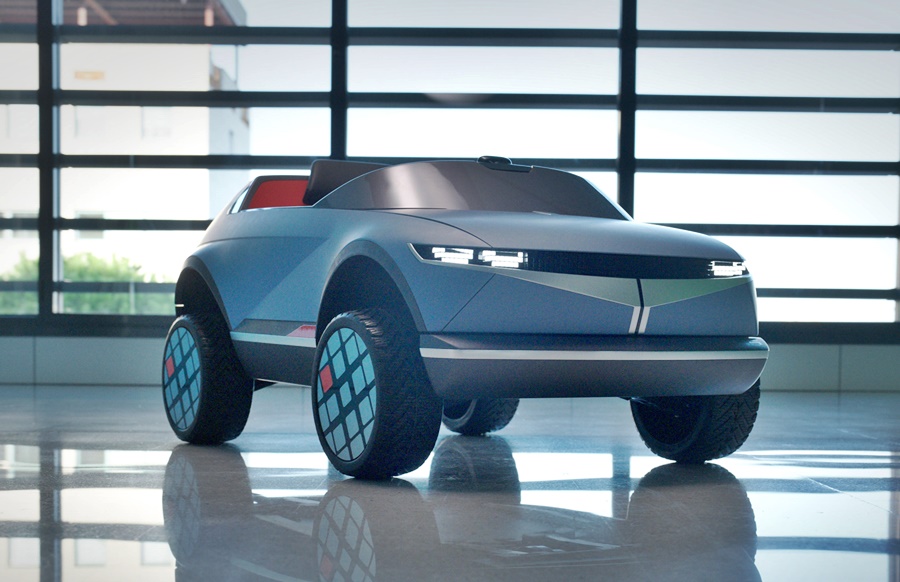

Familiar but fresh design

50 years ago, when cars of the future were displayed at motorshows, they either looked way too extreme or were small bubbles on wheels. However, the iX, while having a pioneering character, has familiarity in its design. It is not extreme, but the exterior represents a distinctive re-imagining of the proportions of a large BMW SAV.

The iX is comparable with the X5 in length and width, and is almost the same height as the X6 on account of its flowing roofline. The size of its wheels would bring to mind the larger X7. The minimalist use of character lines and generously shaped surfaces conjure an aura of supreme assurance. The crisp lines, clear structure and almost rectangular contours around the wheelarches contribute to an imposing body design with optimised aerodynamics.

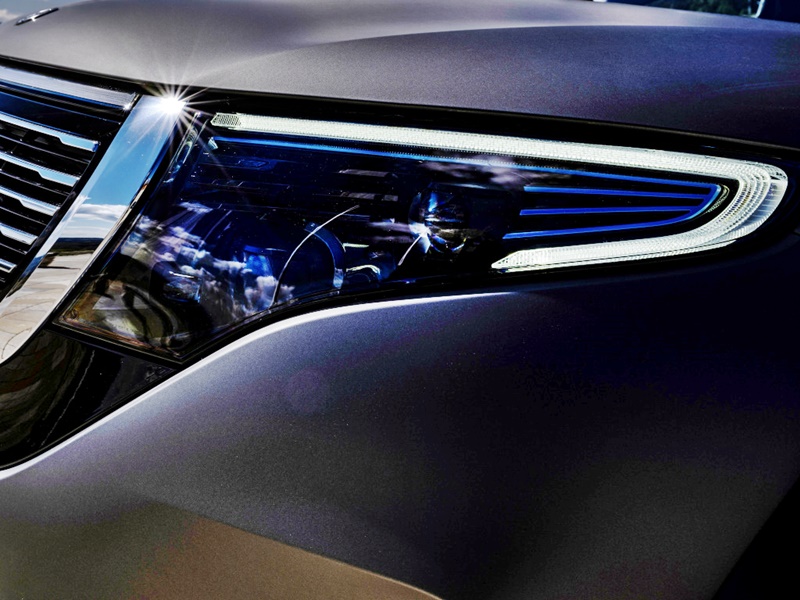

At the centre of the front end stands the prominent, vertically emphasised kidney grille. Since the electric drive system requires only a small amount of cooling air, the kidney grille is completely blanked off. Its role has duly turned digital and here it functions as an ‘intelligence panel’. Camera technology, radar functions and other sensors are integrated into the grille behind a transparent surface.

Developed and produced at the BMW Group’s LuTZ lightweight design and technology centre, the kidney grille for the BMW iX presents a technologically lavish advertisement for intelligent mobility. The grille has reinvented itself as an innovative and multifunctional high-tech interface for the advanced driver assistance systems with which the iX paves the way for automated driving.

Discreetly integrated technology

The exterior design highlights also include the slimmest headlight units ever to feature on a volume-produced model from BMW; the flush-fitted door openers (operated at the press of a button); the frameless side windows; the tailgate (which has no separation joints and extends across the whole of the rear) and the likewise extremely slim rear lights.

The BMW kidney grille is not the only example of how the principle of ‘shy tech’ has been integrated into the design of the BMW iX: an array of other cameras and sensors are likewise positioned discreetly, the filler neck for the windscreen washer fluid is concealed under the BMW logo on the bonnet and the rear-view camera has been integrated into the BMW logo on the tailgate. The technology stays in the background and only becomes apparent as and when the relevant functions are called into action.

“The BMW iX shows how we can give new technologies a very modern and emotionally engaging design. The car is technologically highly complex, but it feels very clear and uncomplicated,” explained Adrian van Hooydonk, Senior Vice-President BMW Group Design. “The BMW iX offers a mobile living space in which people will feel at ease and the car’s intelligence is always available without becoming obtrusive.”

Interior design: people at centre stage

A high level of spaciousness, a mixture of high-quality materials, newly developed seats with integral head restraints and an exceptionally large panoramic glass roof immerse all 5 seats of the cabin in a luxurious, lounge-like ambience. The all-new architecture of the iX cabin underpins a perfectly clear and straightforward functionality that revolves entirely around the needs and emotions of the driver and their fellow occupants.

The drive concept means there is no centre tunnel, adding to the open, airy feel while also allowing extra legroom in the front and rear, sufficient space for storage facilities, and a centre console crafted to look like a high-quality piece of furniture.

The displays and controls are all stripped down to the essentials, further reinforcing the impression of an uncluttered cabin offering a place of relaxation. The technology used intelligently and only becomes visible when it is needed. This makes it intuitive to use rather than seeming overly complex.

The Head-Up Display’s projector is discreetly recessed into the instrument panel, so it is almost invisible. The hexagonally shaped steering wheel, a rocker switch for gear selection and the BMW Curved Display – which forms part of the next-generation BMW Operating System – clearly advertise the futuristic cockpit.

Intelligent lightweight design

The energy and range of the iX benefit from innovative solutions in the areas of lightweight design and aerodynamics. Its body structure, featuring an aluminium spaceframe and innovative Carbon Cage, can claim extremely high torsional stiffness, which in turn enhances agility and maximises occupant protection, while minimising weight. The intelligent material mix, with a variety of materials employed exactly where their specific properties can be utilised to best effect, is unique in this segment.

Together with the superior aerodynamics (0.25 Cd), the intelligent material mix helps to endow the iX with remarkably composed, relaxed driving characteristics combined with instant, precise response to every movement of the accelerator and turn of the steering wheel.