The Malaysian market is greatly appreciated by Honda Motor as this is one of the global markets where the brand enjoys a strong position. It has achieved this success for many years now because it understands that Malaysians like new and advanced technologies and features in their cars. This has led to Malaysia being the first market to launch a new product or technology outside Japan.

With the latest 5th generation Honda City RS e:HEV, Honda again gives Malaysian such an honour. This is the first time in the Asia & Oceania region that Honda is introducing its e:HEV (Hybrid Electric Vehicle) with an advanced 2-motor hybrid system using an intelligent Multi-Mode Drive (i-MMD).

Another first for Malaysia

This follows other firsts by Honda Malaysia over the past 8 years. It was the first company to assemble hybrid cars locally (and the third country among Honda globally after Japan and USA) and the only country outside of Japan to introduce the Sport Hybrid i-DCD (intelligent-Dual Clutch Drive) with the Jazz Hybrid and previous City Hybrid as well as the HR-V Hybrid.

Malaysia gets the honour of being first because this is where Honda sells the most hybrid models in its Asia & Oceania region. Over the past 5 years, 40% of its hybrid models sold in the region have been in Malaysia. So, as part of its plan to increase e:TECHNOLOGY, it is introducing the new City with i-MMD.

Hybrid technology advanced

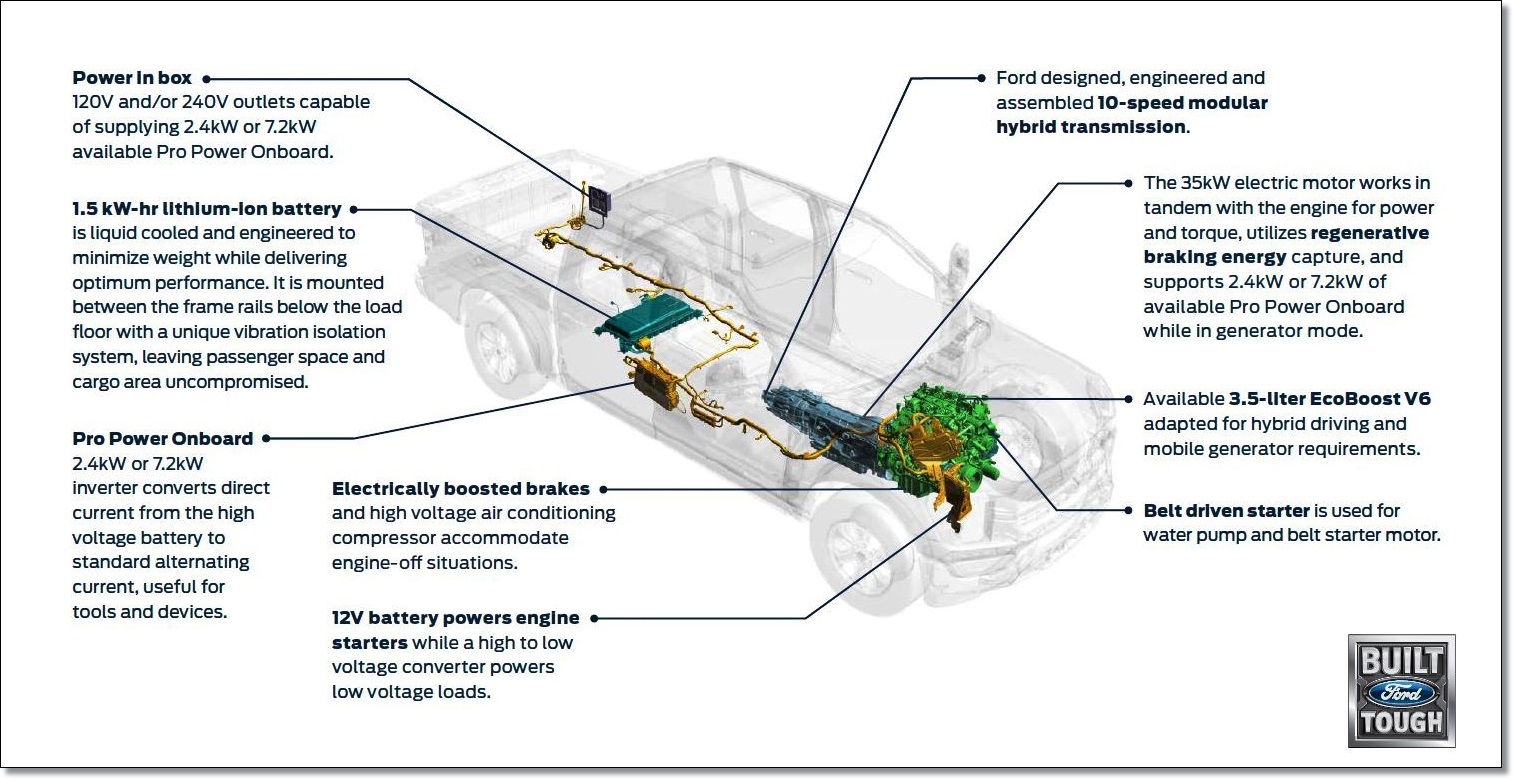

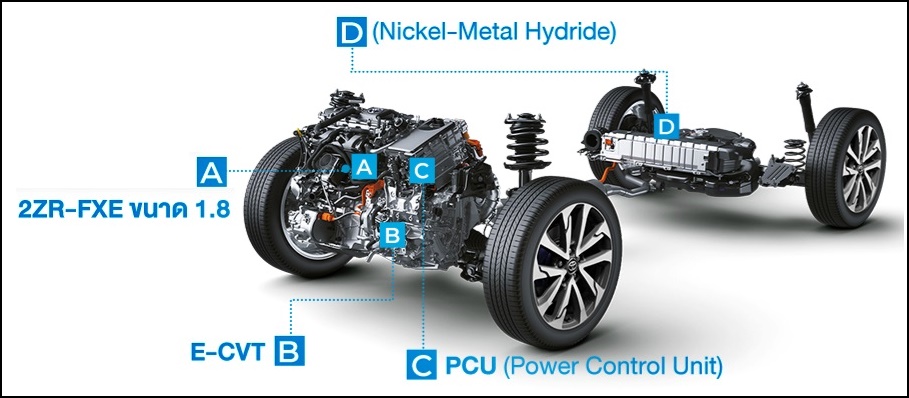

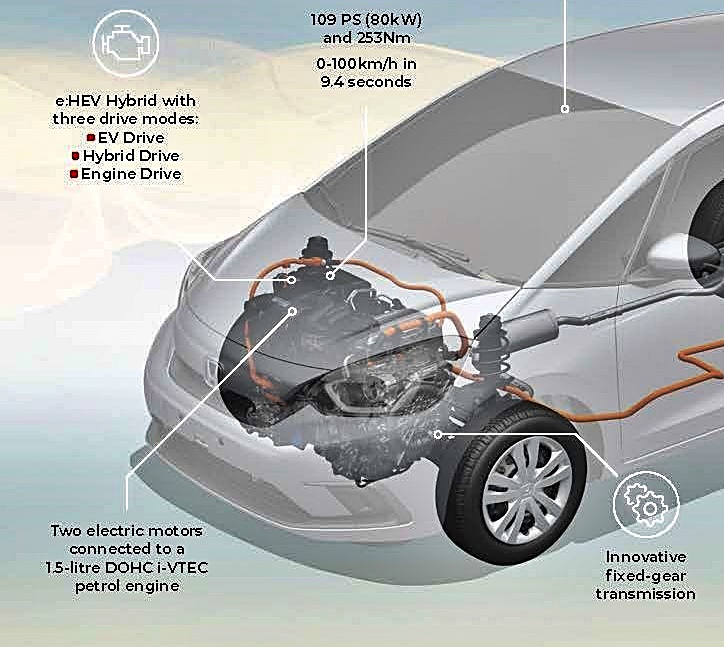

Hybrid technology uses both an internal combustion engine, with a 1.5-litre displacement in the new City, and an electric motor. An Intelligent Power Unit (IPU) seamlessly manages power flows in three modes: EV Drive which is purely electric; Hybrid Drive which combines use of both engine and motor; and Engine Drive which draws power only from the engine.

The choice of modes depends on driving conditions as well as the available energy in the lithium-ion battery pack which is also continuously recharged while driving. EV Drive is usually used when starting off and cruising steadily, while Hybrid Drive optimizes running efficiency. Engine Drive will activate at higher speeds, during which time the battery pack will also be recharged.

An electric motor can generate maximum torque the moment the car starts moving off, and this means the driver has up to 253 Nm of torque available right away. This great amount of torque – highest in its class and even more than cars with bigger engines – is generated up to 3,000 rpm so acceleration remains strong. Overtaking can be done quickly and safely and with a system power output of 108 ps, the City can reach its top speed of 173 km/h very quickly.

For added efficiency, the i-MMD uses an Electric CVT to transmit power to the front wheels. The optimum ratio is computer-selected but the driver can manage deceleration more effectively with a Deceleration Selector Pedal, reducing the need to use the brakes.

Exclusive styling for the RS

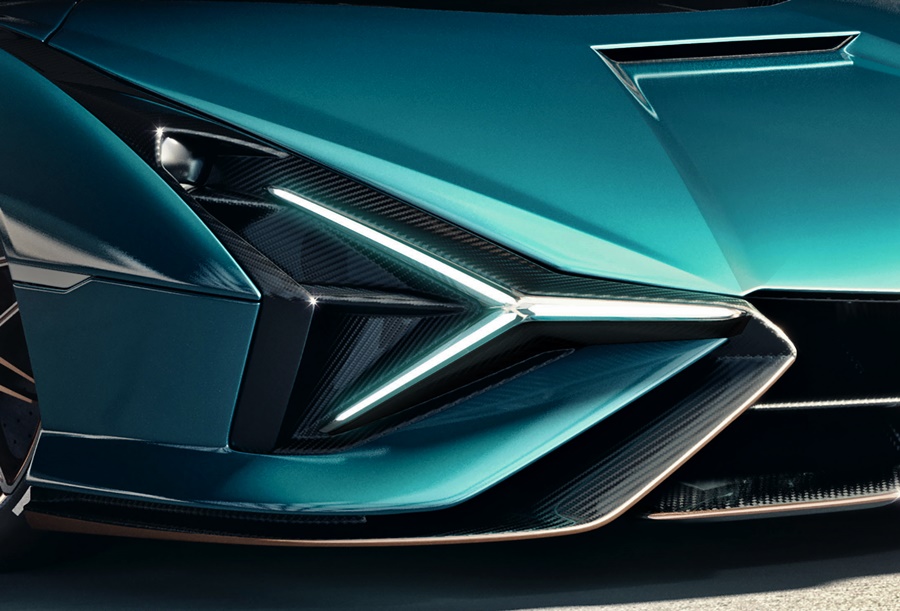

Naturally, with such advanced technology, Honda Malaysia also wants the City RS to stand out more distinctly. This is achieved by giving exclusive styling features to the variant. The grille has a high-gloss Piano Black finish with the RS badge clearly identifying the variant. The slim LED headlights have an eye-catching design and incorporate LED Day Running Lights (DRLs) that give a specific lighting signature. The headlamps can be set to come on automatically whenever lighting conditions are dim, an added convenience.

At the rear, the LED combination lamps also create a distinct lighting signature that immediately identifies this as a special City variant. The wraparound design enables illumination to be spread over a wider range for driving safety.

Emphasizing the sportiness of the City RS is a slim Piano Black spoiler on the edge of the bootlid. Apart from the looks, this helps to manage airflow as it departs from the car body, reducing turbulence that causes drag.

As to be expected, the City RS gets its own exclusive lightweight alloy rims with a multi-spoke design. 16 inches in diameter and with a dual-tone finish, they are fitted with 185/55 tyres that have been chosen by Honda engineers for this car.

Premium look and feel within

The cabin, more spacious with the increased size of the new generation, has become more refined, with increased sophistication and a premium feel on every surface. Switchgear is placed within easy reach with the aim of allowing the driver to keep eyes on the road ahead. For example, the controls for adjusting the automatic air-conditioning system are rotary knobs which are easy to operate even without looking, while the Electric Parking Brake is easily operated with just a press or pull of a finger.

The icons on the full colour 8-inch display are also large, making selection easy. The infotainment system, which includes an 8-speaker surround-sound audio system, easily connects with compatible smartphones using Apple CarPlay or Android Auto. This allows favourite apps to be mirrored on the screen, from which they can be managed. With Waze or Google Maps accessible from the dashboard, driving will become easier as traffic conditions are visible and warnings can be heard too.

A 7-inch TFT screen is used for the instrument panel, giving sharp and clear displays in all lighting conditions. A tripcomputer provides driving information with a real-time fuel consumption bar to help the driver achieve economical motoring. The left dial shows power generation and also the chare level of the battery pack.

The premium image is enhanced by the upholstery for the seats – Ultrasuede, a synthetic ultra-microfibre fabric with a soft, elegant texture and feel. Red stitching and sports pedals with polished metal finish add a sporty touch.

For convenience, there’s keyless entry with pushbutton starting/stopping of the engine. The driver can also start the engine from outside the car using the key fob. This allows running of the air-conditioning system so that the cabin can be cooled down before entry – certainly a welcome feature in our climate!

Honda SENSING comes to the City

It’s not just powertrain technology that is advanced in the new City RS. The new model now has Honda SENSING assistance technologies to help the driver. There are seven systems, all of which use a wide-view camera mounted at the top of the windscreen. Images captured in real-time are analysed by the on-board computer to determine hazardous situations and conditions that have a risk of an accident.

When Adaptive Cruise Control (ACC) is on, the car will travel at a set cruising speed, However, when another vehicle is detected ahead, the speed will be adjusted so that a safe gap is maintained. If there is no longer a vehicle ahead, the set speed will be resumed automatically.

When ACC is not used, Honda SENSING will still monitor the road ahead and if there is a risk of a collision with a vehicle ahead, the driver will be alerted. Should no action be taken (like braking or slowing down), the system will take over and activate the brakes to reduce speed and stop the car. This will help in avoiding a collision in case the driver has lost concentration, and it can also help reduce damage and repair cost as the early deceleration will reduce the impact speed.

As the car is moving, Honda SENSING monitors the lines on the road and notes the position of the car within the lane. Should the driver become drowsy and not maintain full steering control, the car may start to move out of its lane. When this happens, the system will vibrate the steering wheel to alert the driver. In some cases, the system will also gently apply corrective force to steer the car back to the centre of the lane.

There is also the possibility of the car being driven too close to the edge of the road. Honda SENSING is also programmed to detect this and besides alerting the driver, will use steering control and even the brakes to correct the car’s movement.

Auto High Beam is another system in Honda SENSING which gives the driver maximum illumination of the road ahead when possible. Whenever there is no oncoming vehicle, the headlights will switch to the brighter and longer-range high beam, automatically dipping to low beam if a vehicle is detected. This will avoid blinding and irritating the other driver, contributing to safety.

While Honda SENSING is a new feature, exclusive to the City RS, other safety systems such as Vehicle Stability Assist, ABS, EBD and Hill-Start Assist are also present. Additionally, besides dual front SRS airbags, the City RS also has side and window curtain airbags for added protection during side collisions. There is also an Auto Brake Hold feature to make driving in a traffic jam less stressful.

Honda LaneWatch

For the first time, the City gets Honda LaneWatch, an innovative camera-based system which provides the driver with a real-time view of the blind spot along the left side of the car. The advantage of this system is that the driver does not need to turn the head so much to see the traffic situation (unlike having to turn a lot to see the door mirror). The LaneWatch display automatically comes on whenever the signal indicator is activated.

While LaneWatch provides a view of the left side, a Multi Angle Rear View Camera covers the back of the car. This helps the driver position the car properly in a parking bay by showing three different views – wide, normal and high-angle. Each view can be chosen at the touch of a button, appearing clearly on the display even at night when lighting conditions are low.

With so many safety systems to help the driver, plus the G-FORCE CONTROL (G-CON) body structure, it is not surprising that the City can score maximum points from ASEAN NCAP. The G-CON structure dissipates the energy of a collision before it can reach the occupants and cause serious injuries.

Joy of Buying and Owning

Honda Malaysia often talks about giving customers the Joy of Buying with its products, and complementing this would be the Joy of Owning. This comes in many ways that will give peace of mind to the owner. Reliability and durability are a given with any Honda, along with high quality of assembly. The warranty will be for a full 5 years as there is no limit on mileage, and a further 3 years for the hybrid battery pack.

The all-new Honda City RS e:HEV will be available in January 2021 but authorized Honda dealerships nationwide will be happy to accept a booking now. To locate a showroom nearest to you, visit www.honda.com.my or by calling 1-800-88-2020.